Solid forms of an epidermal growth factor receptor kinase inhibitor

A form of solid technology, used in plant growth regulators, biocides, animal repellants, etc., to solve problems such as dose-limiting toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0227] Preparation Form A

[0228] Approximately 120 mg of Compound 1 was weighed into a vial and slurried in approximately 2 ml of acetonitrile. This slurry was temperature cycled between about 0°C and ambient (about 22°C) in a 2 hour cycle with stirring for a period of 2-3 days. Keep samples at about 2-5°C overnight. The solid material was separated and allowed to dry under vacuum for 7 days.

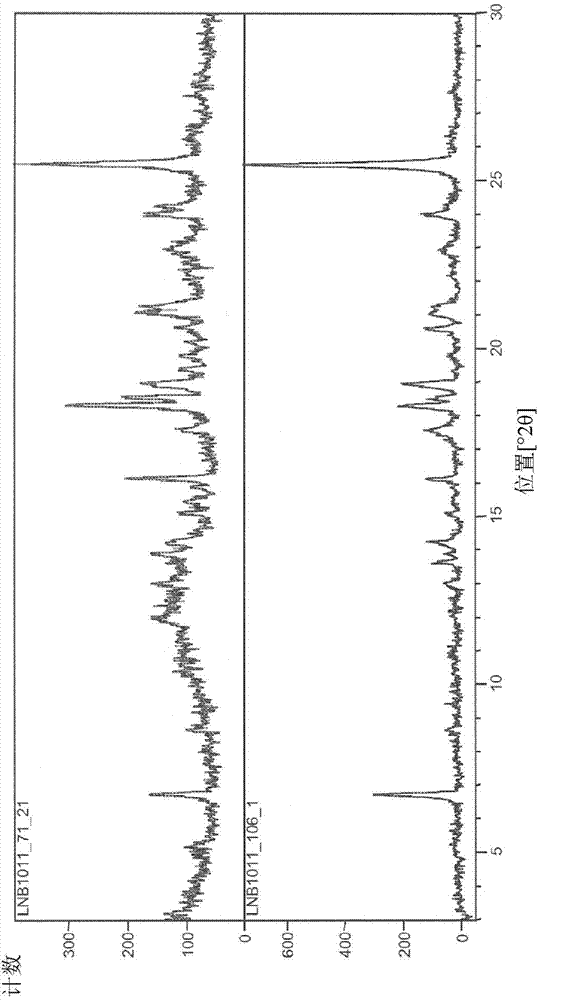

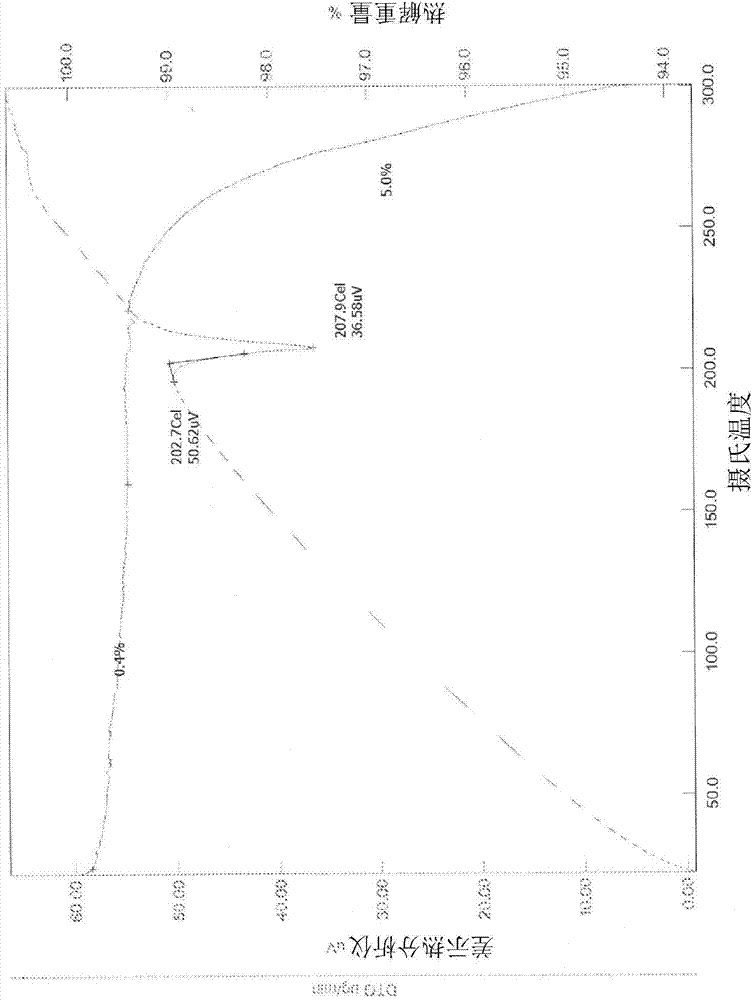

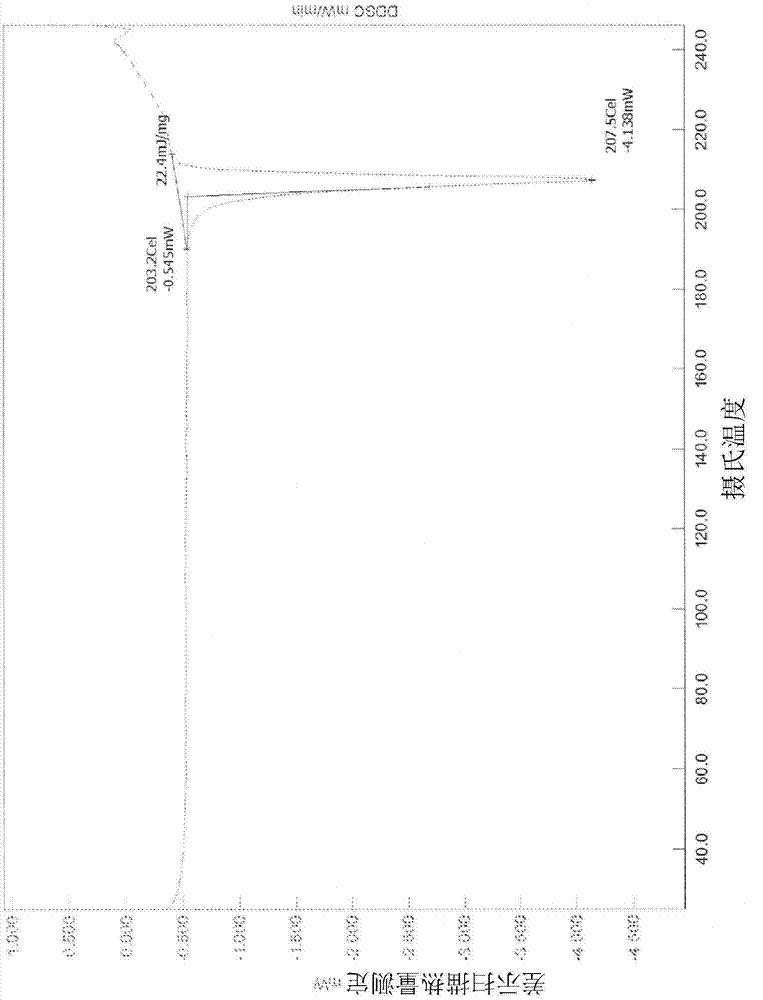

[0229] XRPD analysis ( figure 1 ) shows that the material is crystalline. PLM analysis (not shown) indicated very fine birefringent needles. TGA / DTA ( figure 2 ) shows a 0.4% weight loss from start to about 150°C, probably due to unbound solvent. No significant weight loss was seen prior to degradation. DSC analysis ( image 3 ) shows a single endotherm at onset about 203.2°C (peak 207.5°C) due to melting. IR analysis ( Figure 4 ) is consistent with the input free base substance. in deuterated DMSO 1 H NMR (not shown) showed a spectrum consistent with the input free bas...

example 2

[0232] Preparation Form B

[0233] About 120 mg of compound 1 was weighed into a vial and slurried in about 2 ml of tetrahydrofuran. This slurry was temperature cycled between about 0°C and ambient (about 22°C) in a 2 hour cycle with stirring for a period of 2-3 days. Keep samples at about 2-5°C overnight. The solid material was separated and allowed to dry under vacuum at ambient for 7 days and at 40° C. for 2 days.

[0234] XRPD analysis ( Figure 6 ) shows that the resulting material is crystalline. PLM analysis (not shown) indicated birefringent rod crystals. TGA / DTA ( Figure 7 ) shows no significant weight loss before degradation after 7 days of ambient drying under vacuum and a further 2 days at 40°C. DSC analysis ( Figure 8 ) shows an endotherm at onset 153.6°C (peak 157.6°), followed directly by an exotherm at peak 161.3°C, indicating a polymorphic transition. There was another small endotherm at peak 186.0°C, followed by a final endotherm at onset 203.9°C (p...

example 3

[0238] Preparation Form C

[0239] Approximately 120 mg of Compound 1 was weighed into a vial and slurried in approximately 100 μl DMF. The slurry was temperature cycled between about 0°C and ambient (about 22°C) in a 2 hour cycle with agitation. After about 2 hours, another 300 μl of DMF was added. The temperature cycle was continued for a period of 2-3 days. Keep samples at about 2-5°C overnight. The solid material was separated and allowed to dry under vacuum at ambient for 7 days and at 40° C. for 2 days.

[0240] XRPD analysis ( Figure 12 ) shows that the material is crystalline. PLM analysis (not shown) indicated birefringent rod crystals. TGA / DTA ( Figure 13 ) showed a weight loss of about 8.2% after 7 days of ambient drying under vacuum and a further 2 days at 40°C (the monosolvate required 11.6 wt% DMF). DSC analysis ( Figure 14 ) showed a broad endotherm between 85-125 °C, consistent with weight loss in TGA. A final endotherm was seen with onset at about...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com