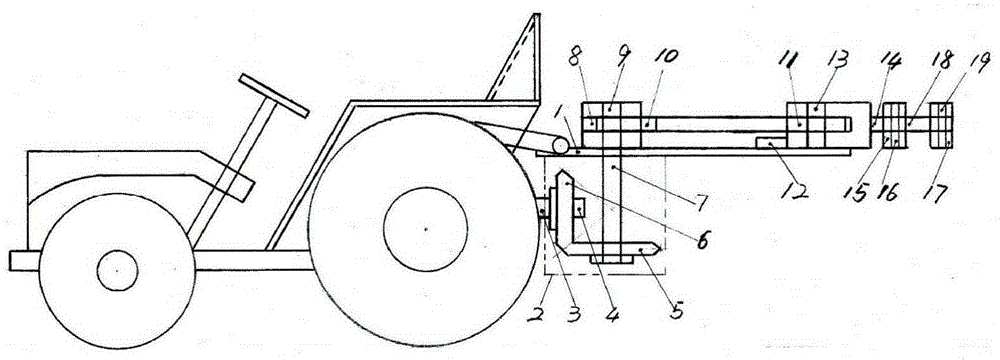

Self-propelled mechanical reciprocating soaked walnut harvester

A technology for soaking walnuts and harvesters, which is applied to agricultural machinery and implements, pickers, harvesters, etc., can solve problems such as troublesome selection of fulcrum rubber cushions, inability to form large swings, and reduced operating efficiency, saving work. Time, easy operation, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

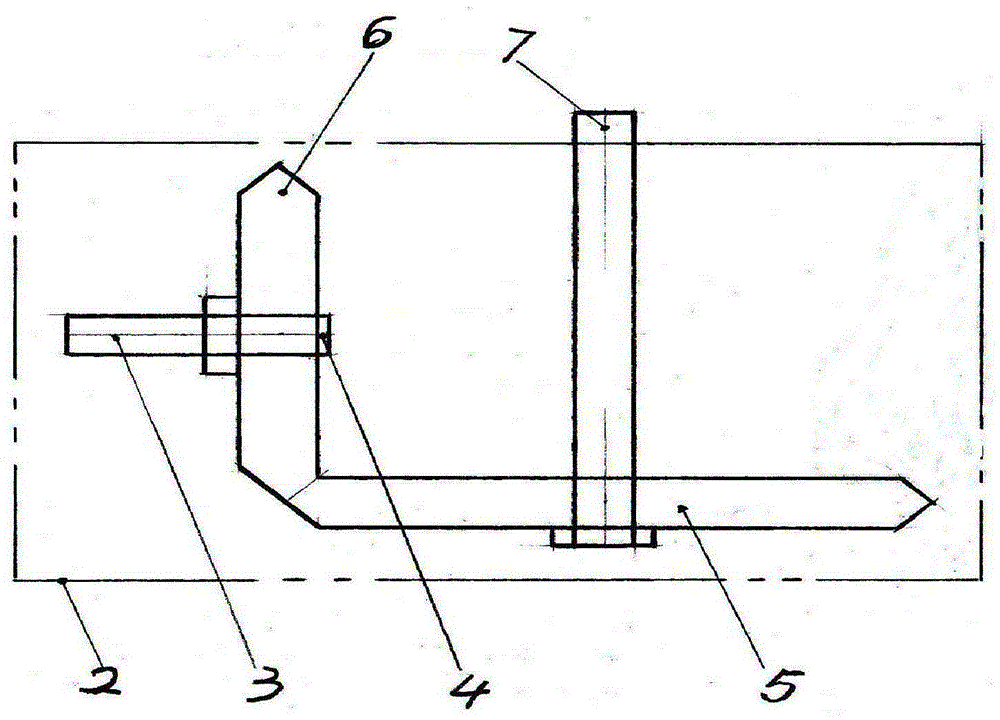

Method used

Image

Examples

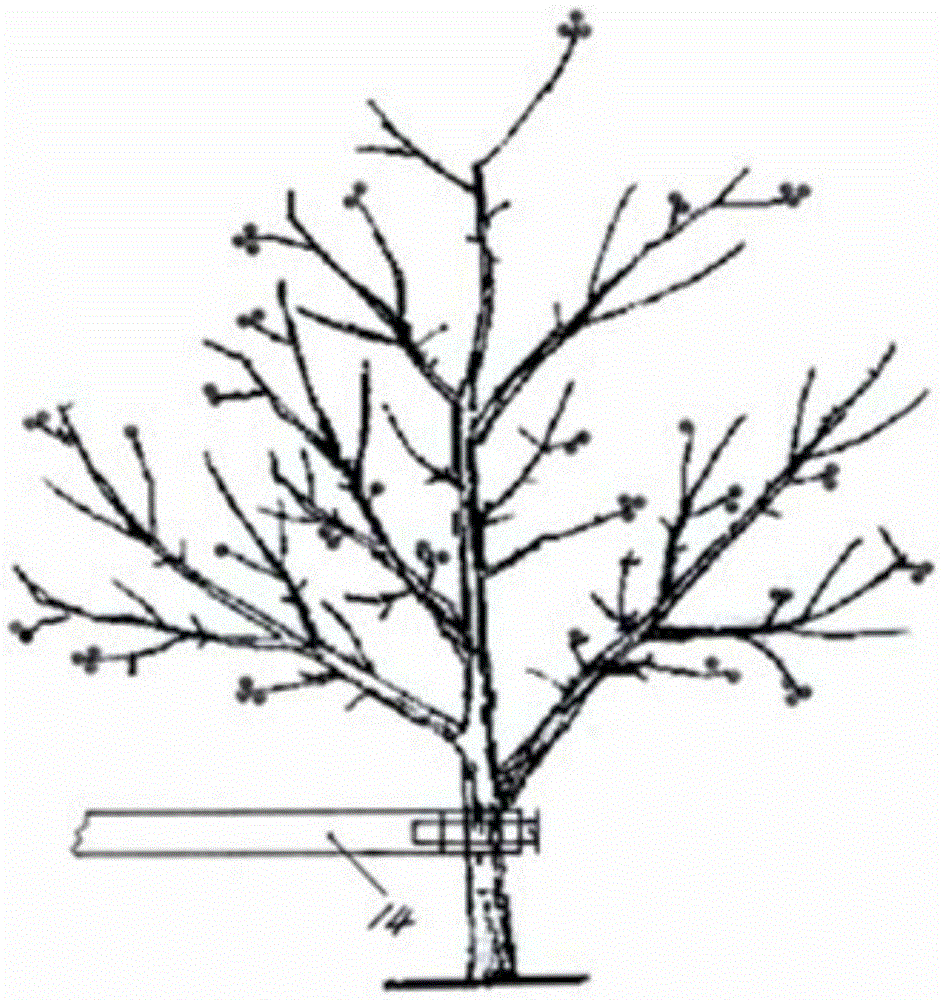

Embodiment 1

[0035] Embodiment 1: This harvester uses four-wheel drive, hydraulic power steering, dry land type, and a medium-sized agricultural tractor with a supporting power of 36.76kw to harvest the soaked walnuts that grow on terraced land, trunk diameter 164mm, and tree age of 8 years. The holding device is located at a distance of 1160mm from the main stem of the soaked walnut plant to the ground. Using the rated operating speed of the engine, the clamping position of the soaked walnut plant can swing up to 50mm, with an average reciprocating swing of 8 times per second, and the whole plant of soaked walnut fruit can be completed once in 13 seconds. sexual harvesting. A total of 609 fresh fruits were harvested, 5 were not harvested, and the recovery rate was 99.2%.

Embodiment 2

[0036] Embodiment 2: This harvester uses a four-wheel drive, hydraulic power steering, dry land type, and a large-scale agricultural tractor with a supporting power of 52.94kw to harvest the pickled walnuts that grow next to the country road, with a trunk diameter of 252mm and a tree age of about 21 years , the clamping device is located at a distance of 1740mm from the main body of the soaked walnut plant to the ground, and the rated operating speed of the engine is used to make the clamping position of the soaked walnut plant swing up to 30mm, with an average reciprocating swing of 8 times per second, and the whole plant of soaked walnut fruit is completed in 15 seconds. one-time harvest. A total of 2752 fresh fruits were harvested, 27 were not harvested, and the recovery rate was 99.0%.

Embodiment 3

[0037] Embodiment 3: This harvester adopts a large-scale agricultural tractor with four-wheel drive, hydraulic power steering, dry land type, and a supporting power of 58.82kw to harvest the pickled walnuts that grow beside the country road, have a trunk diameter of 337mm, and are about 40 years old. , the clamping device is located at a distance of 1910mm from the main body of the soaked walnut plant to the ground, and the rated operating speed of the engine is used to make the clamping position of the soaked walnut plant swing up to 25mm, with an average reciprocating swing of 8 times per second, and the whole plant of soaked walnut fruit is completed in 15 seconds one-time harvest. A total of 3720 fresh fruits were harvested, 47 were not harvested, and the recovery rate was 98.75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com