Automatic rice noodle selling machine

A vending machine and rice noodle technology, applied in the fields of application, food preparation, food science, etc., can solve the problems of hard work, poor sanitation and environmental conditions, and labor-intensive workers, so as to reduce staff, improve sanitation, and save manpower. effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

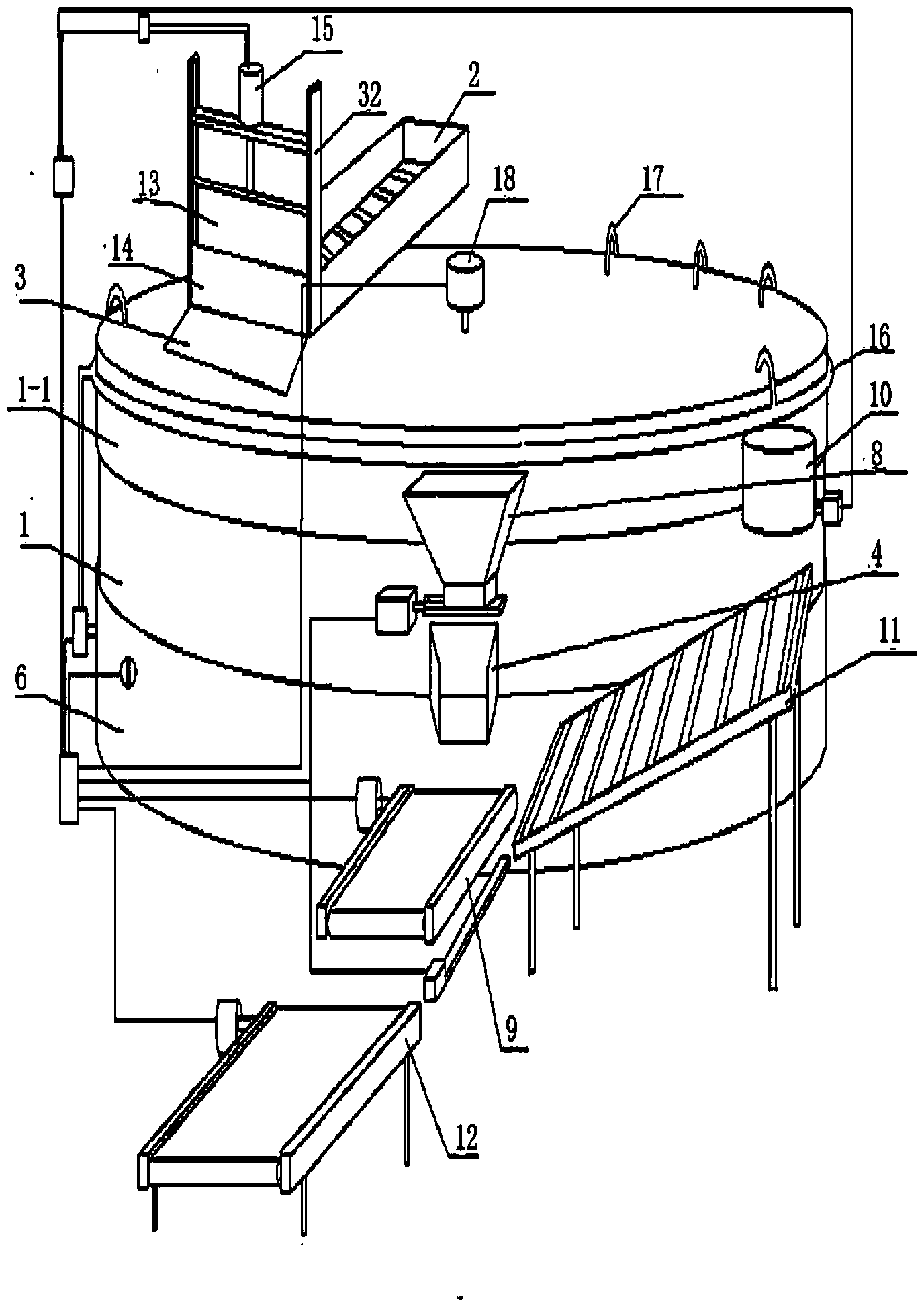

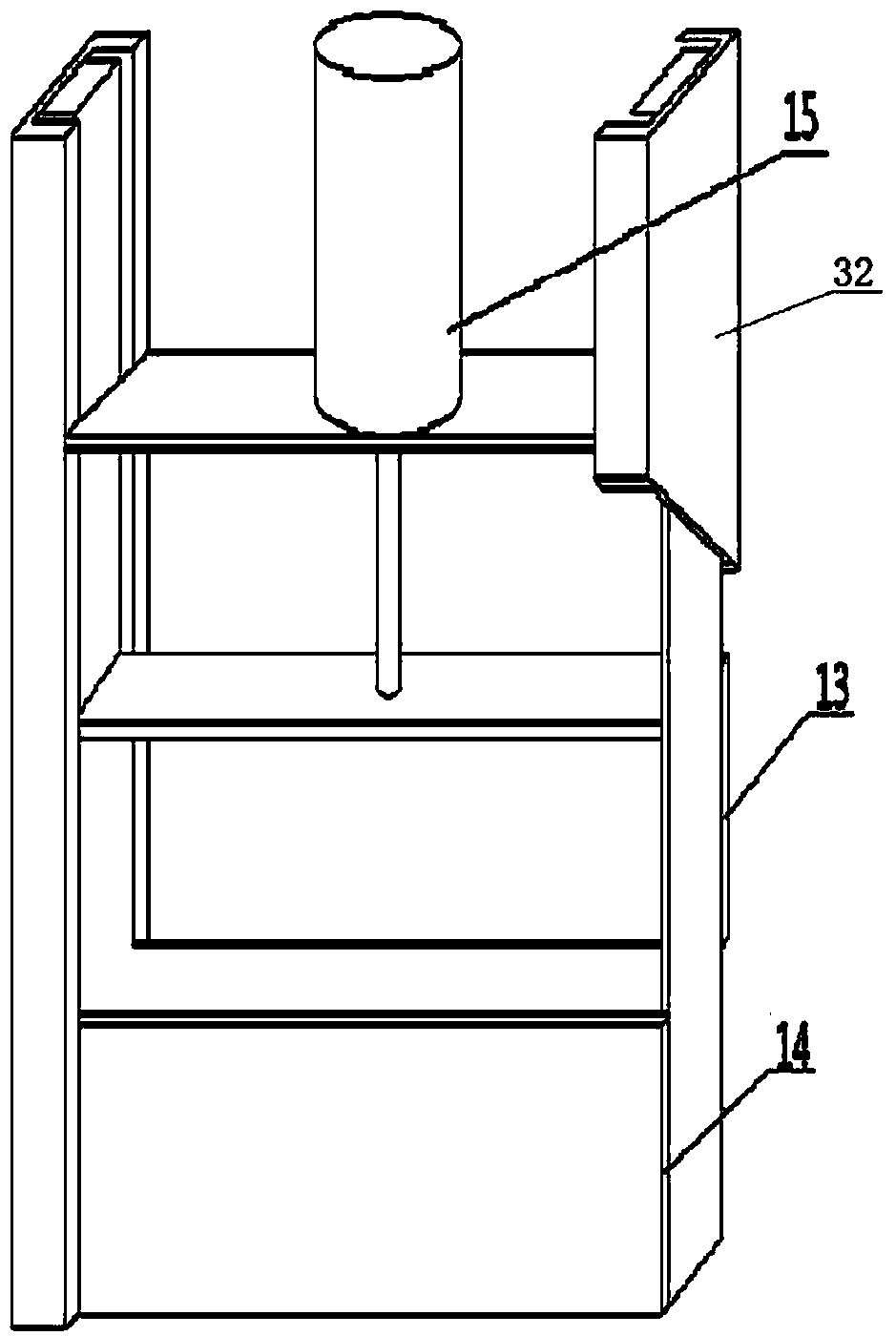

[0039] The automatic rice noodle vending machine of the present invention is mainly composed of a powder cutter, a steam box 1 (round), a hot water tank 6 (round), a meat and vegetable feeder 8, a bowl divider 10, a powder receiving conveyor 9, and a bowl feeding conveyor Constituted with powder outlet conveyor 12.

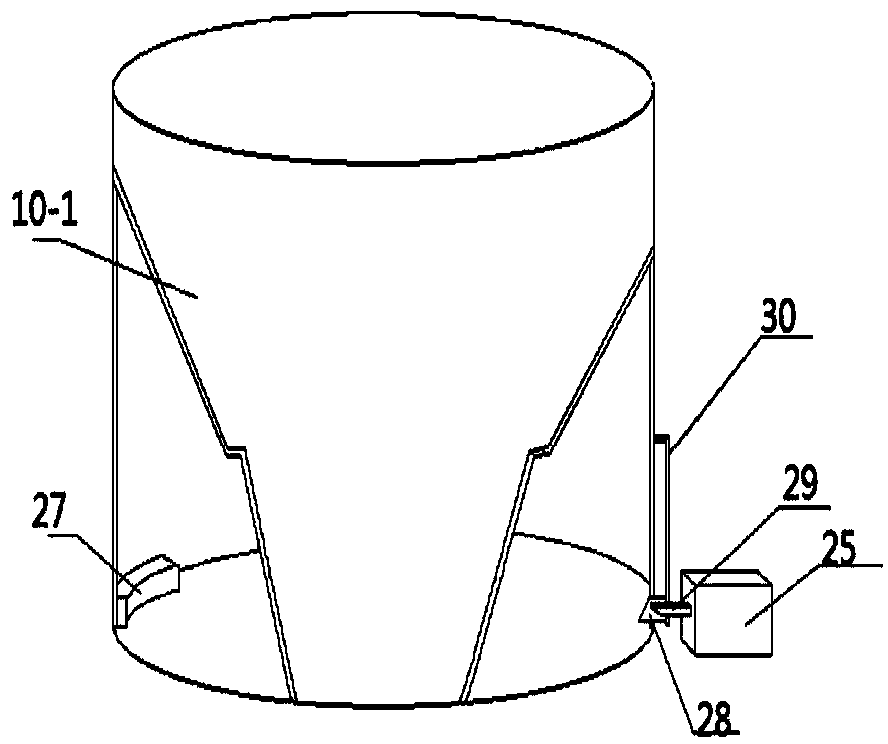

[0040]The steam box 1 and the hot water tank 6 are arranged according to the upper and lower positions, and the lower opening of the steam box 1 and the upper opening of the hot water tank 6 are connected to form a whole, and the upper opening of the steam box 1 is covered by a box cover 1-1, The box cover 1-1 is provided with a powder inlet 3, and an annular water pipe 16 is arranged around the outer circumference of the box cover 1-1. A plurality of water spray pipes 17 communicating with the annular wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com