Chip package dispensing head

A technology of rubber head and chip, which is applied to the device and coating of the surface coating liquid, to achieve the effects of flexible operation, convenient replacement of syringes, and easy adjustment of posture and posture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

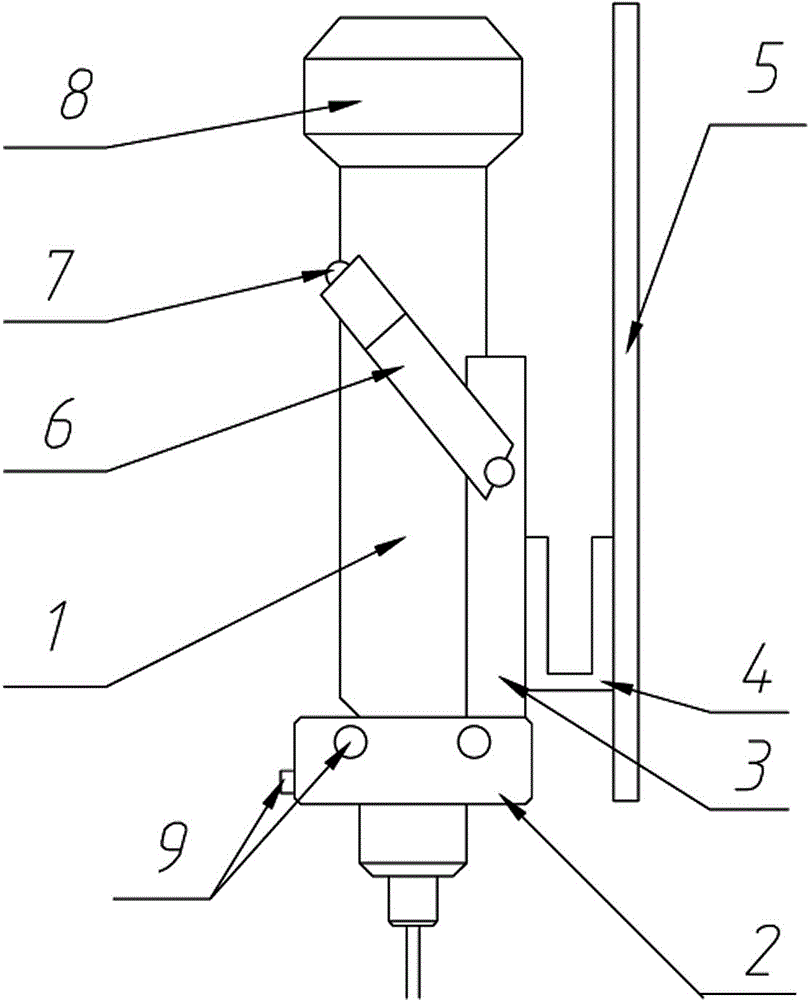

[0010] The chip packaging dispensing head of the present invention includes a syringe 1 and a supporting plate 2, a dovetail groove is opened at the center of the supporting plate 2, a back plate 3 is arranged on one side of the supporting plate 2, and the other side of the back plate 3 is connected The plate 4 is connected with the baffle 5, the head of the syringe 1 passes through the dovetail groove and fixes the syringe head 1, a U-shaped spring clip 6 is arranged on the back plate 3 to fix the tail of the syringe 1, and the end of the U-shaped spring clip 6 An adjusting screw 7 is provided, and a sealing ring is provided at the end of the syringe 1 . Two pairs of eccentric bolts 9 are arranged on the supporting plate 2. The axes of the two pairs of eccentric bolts 9 are perpendicular to each other, and the central axes of the two pairs of eccentric bolts 9 are not on the same plane. The head of the syringe 1 is located between each pair of eccentric bolts 9. between. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com