Camera process protecting film

A protective film and camera technology, which is applied in the direction of synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve the problems of affecting the clarity of the ingested picture, increasing the operating cost of the enterprise, reducing the life of the camera, etc., to save production Maximization of man-hours, benefits, and the effect of improving assembly capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

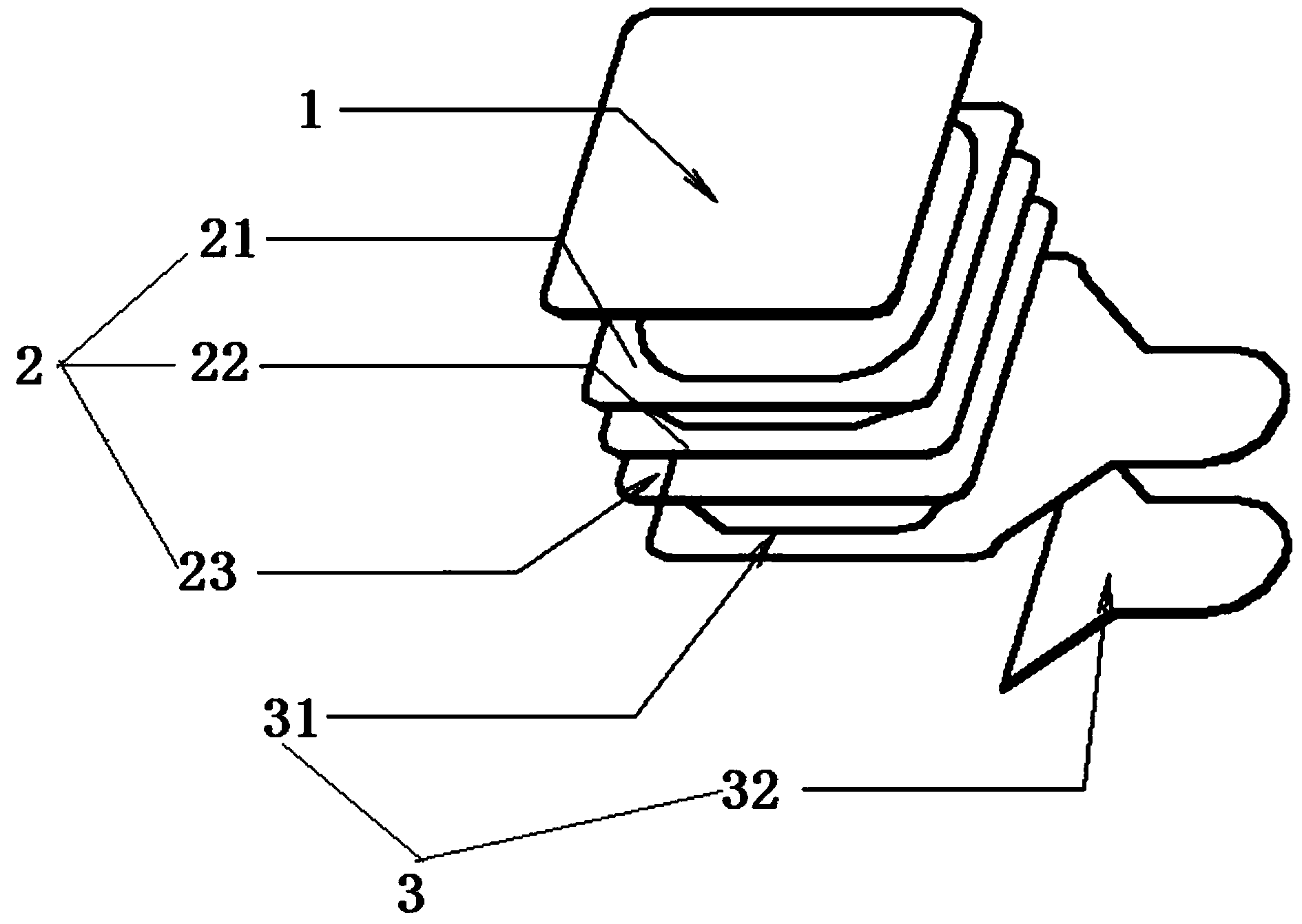

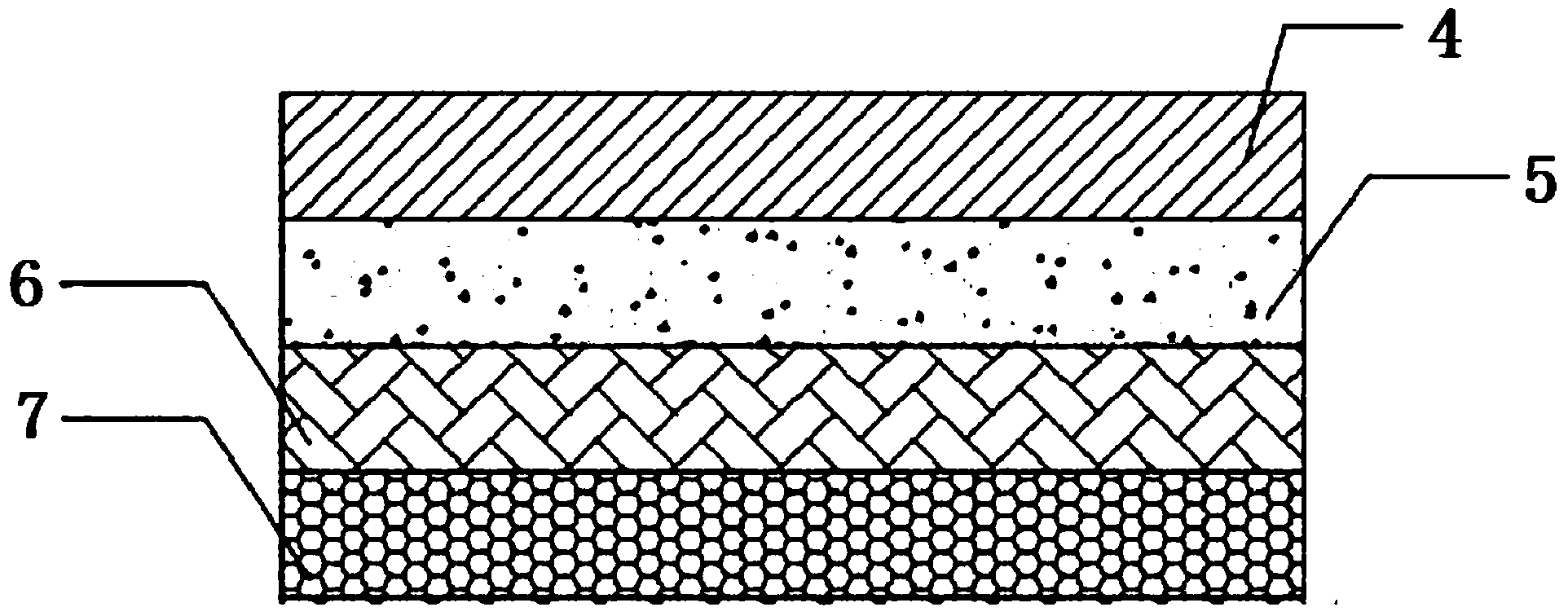

[0016] Such as figure 1 and figure 2 As shown, it is a camera process protective film in accordance with the present invention, which includes from top to bottom: a first protective layer 1, a PET support layer 2 and an adhesive layer 3, and the PET support layer 2 includes a first protective layer from top to bottom. A double-sided adhesive film layer 21, a PET film layer 22 and a second double-sided adhesive film layer 23, the adhesive layer 3 includes a silicone protective film layer 31 and an adhesive-free ear portion 32; wherein the first double-sided adhesive film Layer 21, the PET film layer 22, the second double-sided adhesive film layer 23, and the center of the silica gel protective film layer 31 are all provided with a hollow area, the shape of the hollow area matches the camera, and the PET The thickness of the film layer 22 is 0.1 mm, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com