Internal combustion locomotive double-heading traction drive device

A technology of traction drive and internal combustion locomotive, which is applied to transmission devices and locomotives driven by electric motors. It can solve the problems of large investment, high maintenance costs, and large locomotive dimensions, so as to improve passing capacity, reduce operating costs, and improve The effect of operating economics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

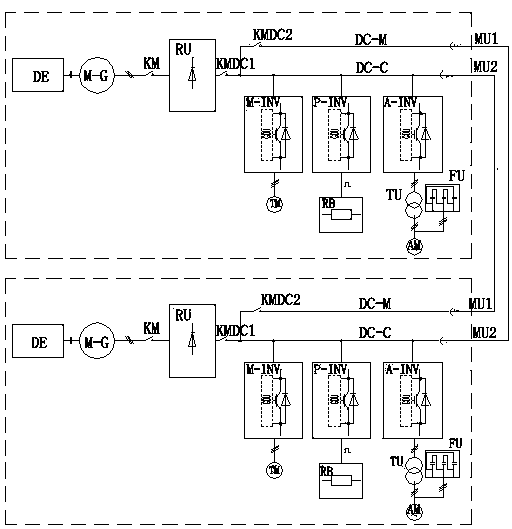

[0025] Such as figure 1 As shown, a double-coupled traction transmission device for a diesel locomotive includes two sets of locomotive main transmission systems, and each set of locomotive main transmission systems includes engine DE, traction generator M-G, distillation unit RU, traction converter M-INV, resistance system Dynamic converter P-INV, auxiliary converter A-INV, traction motor TM, resistance braking device RB, isolation transformer TU, filter device FU, auxiliary electrical equipment AM, the generator DE, traction generator M-G , the rectifying device RU, and the first DC contactor KMDC1 are sequentially connected, and the first DC contactor KMDC1 is then divided into two branches of the locomotive reconnection DC bus DC-M and the locomotive DC bus DC-C, and the locomotive DC bus DC There are three branches on -C, one is connected with the traction motor TM through the traction converter M-INV, one is connected with the auxiliary electrical equipment AM through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com