Dual-fuel bulk cargo ship

A bulk carrier, dual-fuel technology, applied in the direction of bulk cargo, hull, ship construction, etc., can solve the problems of limited fuel tank space, restricting the overall layout, ship design problems, etc., to save the weight of the hull and optimize the overall layout. , the effect of reducing the difficulty of layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the present invention more obvious and understandable, the preferred embodiments are described in detail as follows in conjunction with the accompanying drawings:

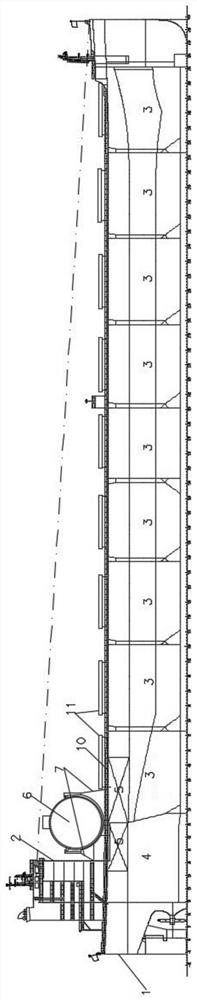

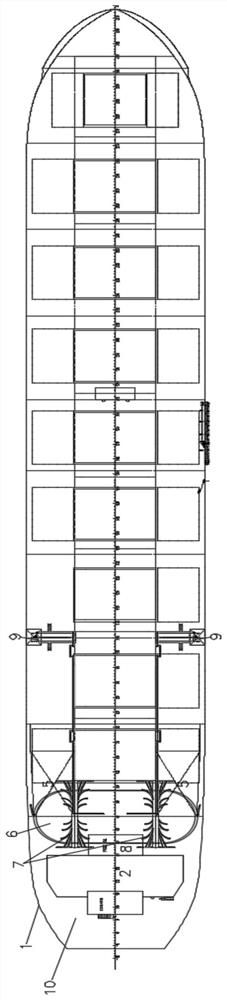

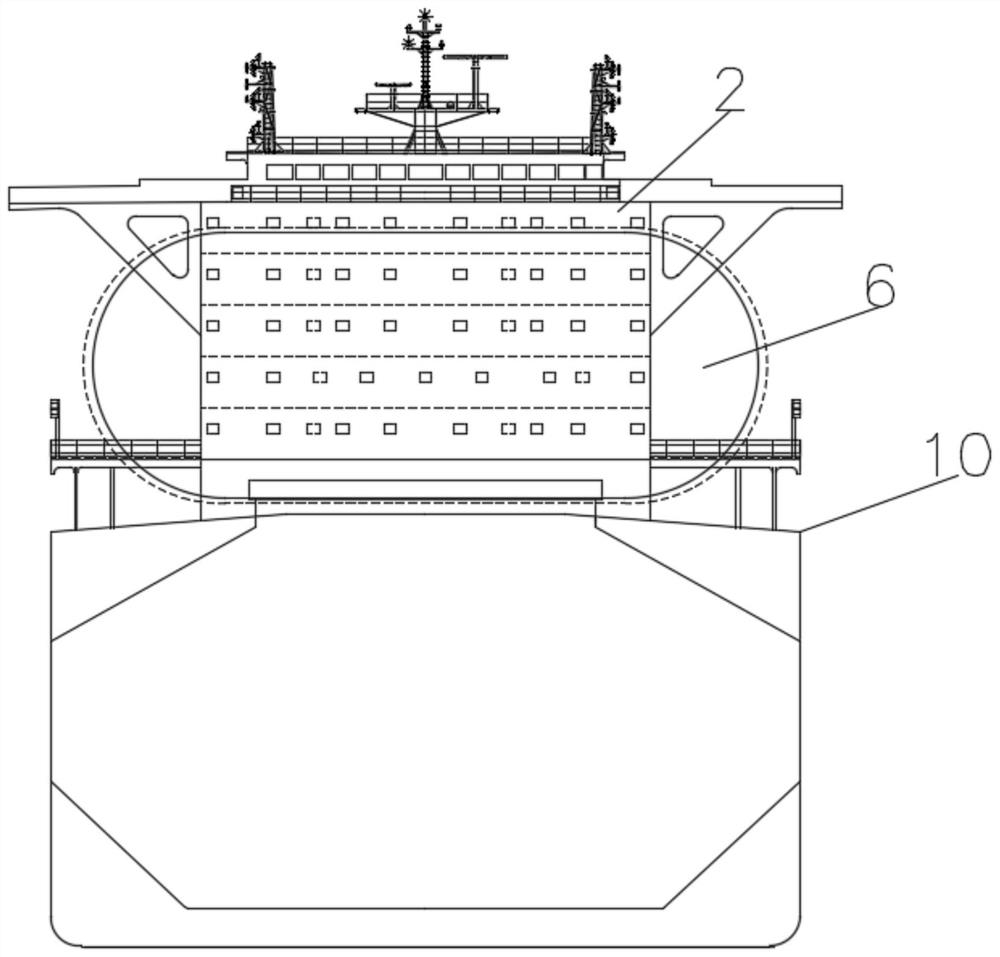

[0030] Such as Figure 1-3 As shown, the present invention provides a dual-fuel bulk carrier, including a superstructure 2, an upper deck 10, a gas fuel tank 6, a fuel oil storage compartment 5, a cargo hold 3 and an engine room 4; the upper deck 10 of the dual-fuel bulk carrier near the stern A superstructure 2 is arranged on it, and an engine room 4 is arranged inside the hull 1 below the superstructure 2, and a cargo hold 3 is arranged inside the hull 1 between the engine room 4 and the bow of the dual-fuel bulk carrier; A gas fuel tank 6 is arranged on the upper deck 10 , and a fuel oil storage tank 5 is arranged inside the hull below the gas fuel tank 6 . A fuel oil storage compartment 5 is arranged between the top of the engine room 4 and the cargo compartment 3 and the upper deck 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com