Ship engine room ventilation assembly

A technology for engine rooms and ships, which is applied in hull ventilation/heating/cooling, ship components, ship construction, etc. It can solve problems that affect the sight and health and safety of construction workers, poor exhaust effect, and dust cannot be discharged quickly and effectively. To achieve the effect of ensuring normal operation and physical health and safety, reducing noise pollution and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

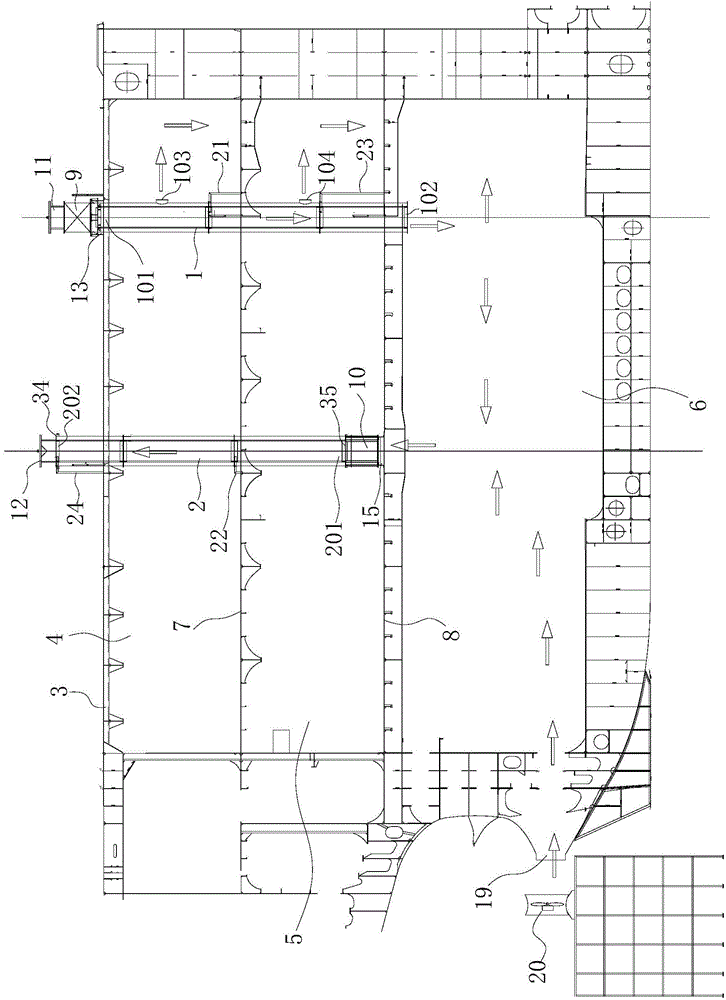

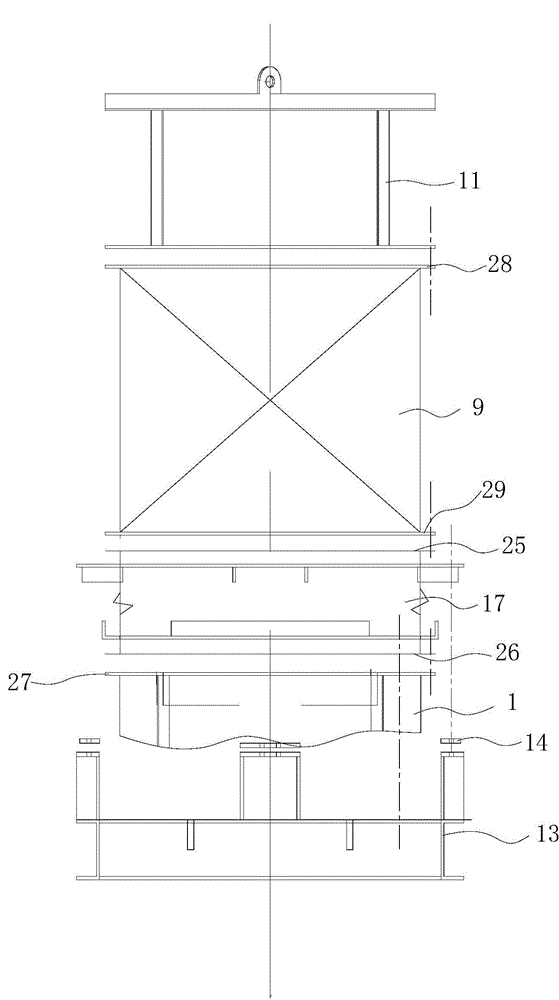

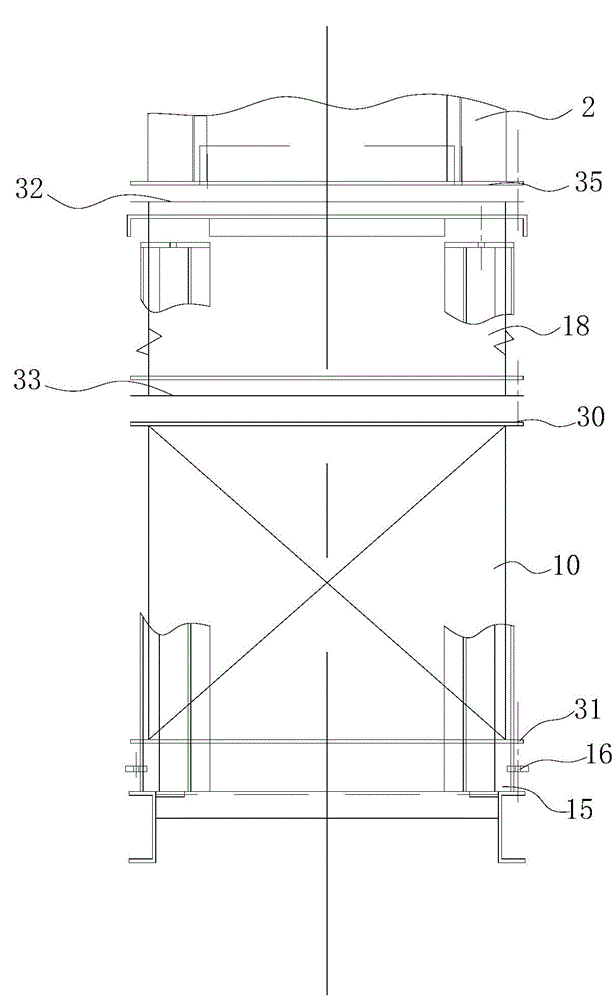

[0070] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0071] Such as Figures 1 to 5 As shown, a kind of marine engine room ventilation assembly of the present invention is mainly applied to ships with three-layer cabins. The deck 3 is set away from the side of the second cabin 5, and the first platform 7 is set between the first cabin 4 and the second cabin 5, so as to separate the first cabin 4 and the second cabin 5 by the first platform 7, and the second cabin 5 A second platform 8 is set between the bottom cabin 6 to separate the second engine room 5 and the bottom cabin 6 through the second platform 8 .

[0072] Among them, the ship engine room ventilation assembly includes an air supply pipe 1 and an air exhaust pipe 2. The air supply pipe 1 passes through the ship's deck 3, the first engine room 4, and the second engine room 5 in order to exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com