Shunting type conveyor belt for packing machine

A conveyor belt and packaging machine technology, applied in the field of lane-separated conveyor belts, can solve the problems of high equipment production cost, high failure rate in use, and slow conveying speed, and achieve the effects of simple structure, reduced equipment cost, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

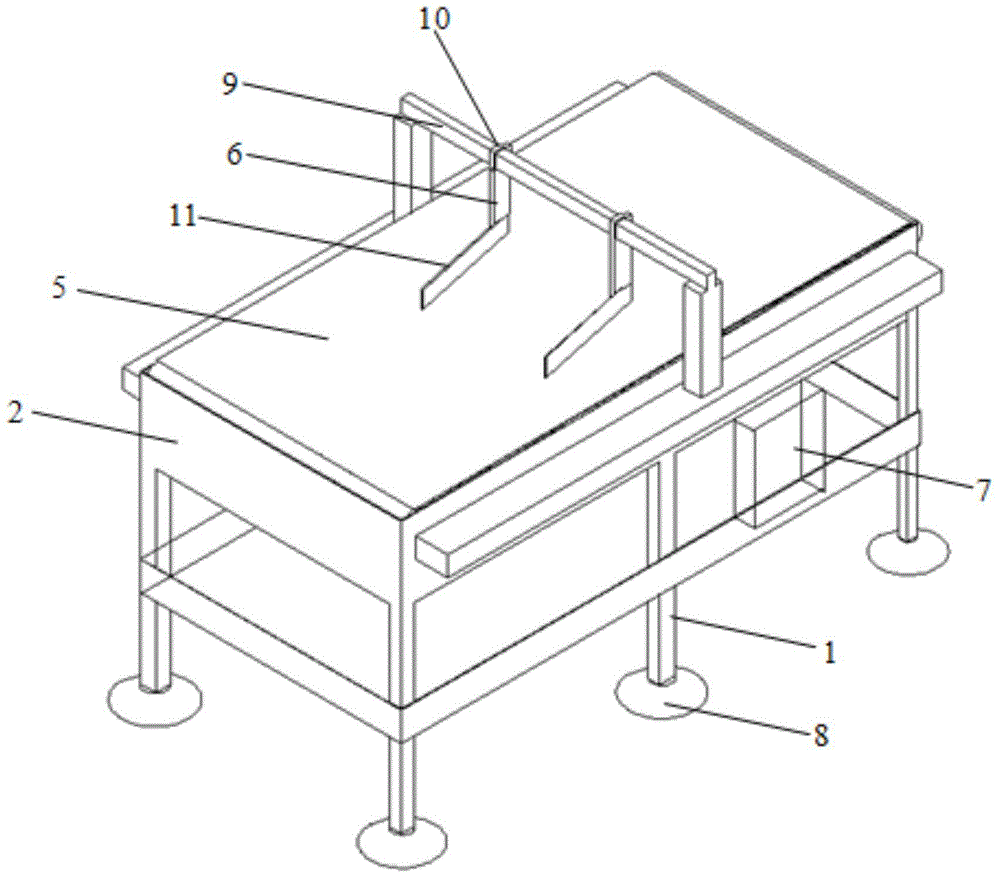

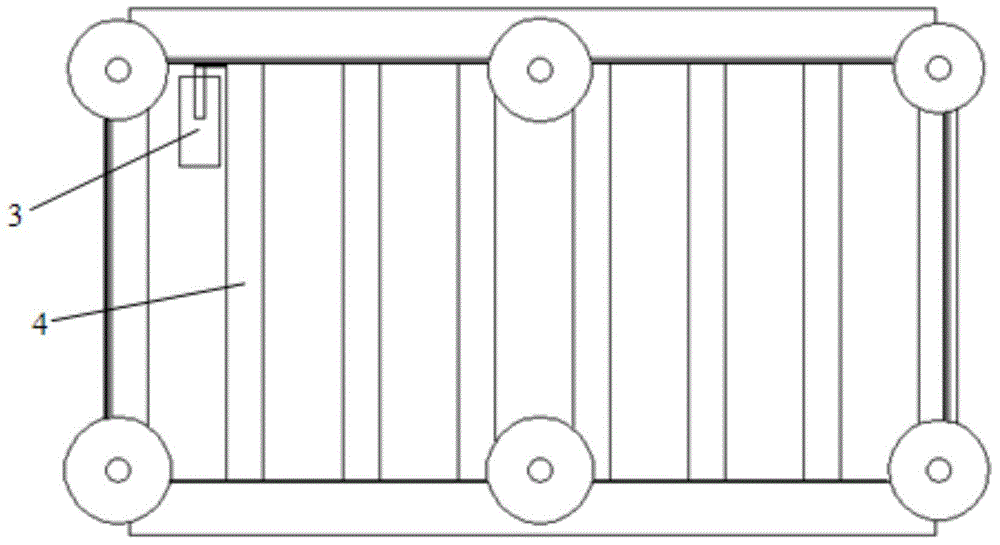

[0015] see Figure 1-2 Said, a lane-dividing conveyor belt for packaging machines, comprising a lane-dividing line body, the lane-dividing line body is composed of a chassis 1, a frame 2, a motor 3, a rolling bearing 4, a belt 5, and a lane-dividing pendulum Sheet 6, control cabinet 7 constitutes. The frame 2 is installed on the bottom frame 1, the motor 1 and the rolling bearing 4 are installed on the frame 2, the material of the belt 5 is canvas or PU, its width is 600-1000mm, and the end and the end are closed and covered on the rolling bearing 4, and the pieces are divided into lanes 6 is installed on the frame 2 and placed on the top of the belt 5, and the electrical components are installed inside the control cabinet 7 to control the operation of the motor 1. The lower part of the chassis 1 is provided with 6 or 8 anchor screws 8. When the device is first installed, the anchor screws 8 need to be adjusted to keep the machine transmission plane level. The lane-dividing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com