An energy-saving aerator for cable production sewage treatment

A technology for the production of sewage and aerators, which is applied in water/sludge/sewage treatment, water aeration, natural water treatment, etc. It can solve the problem of low dissolved air, and achieve the effect of reducing costs, installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

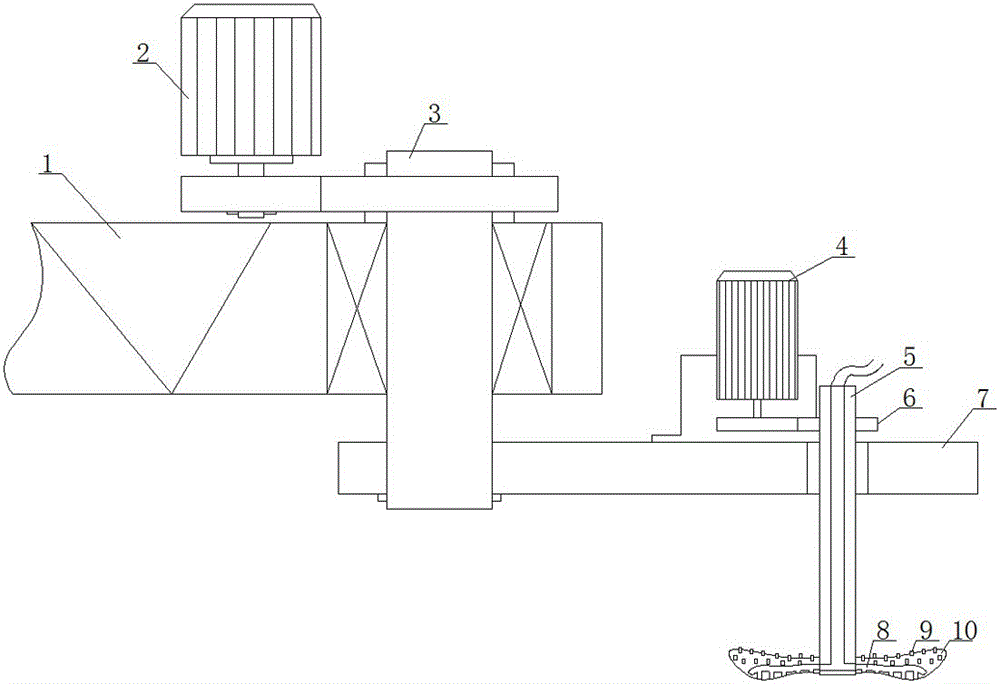

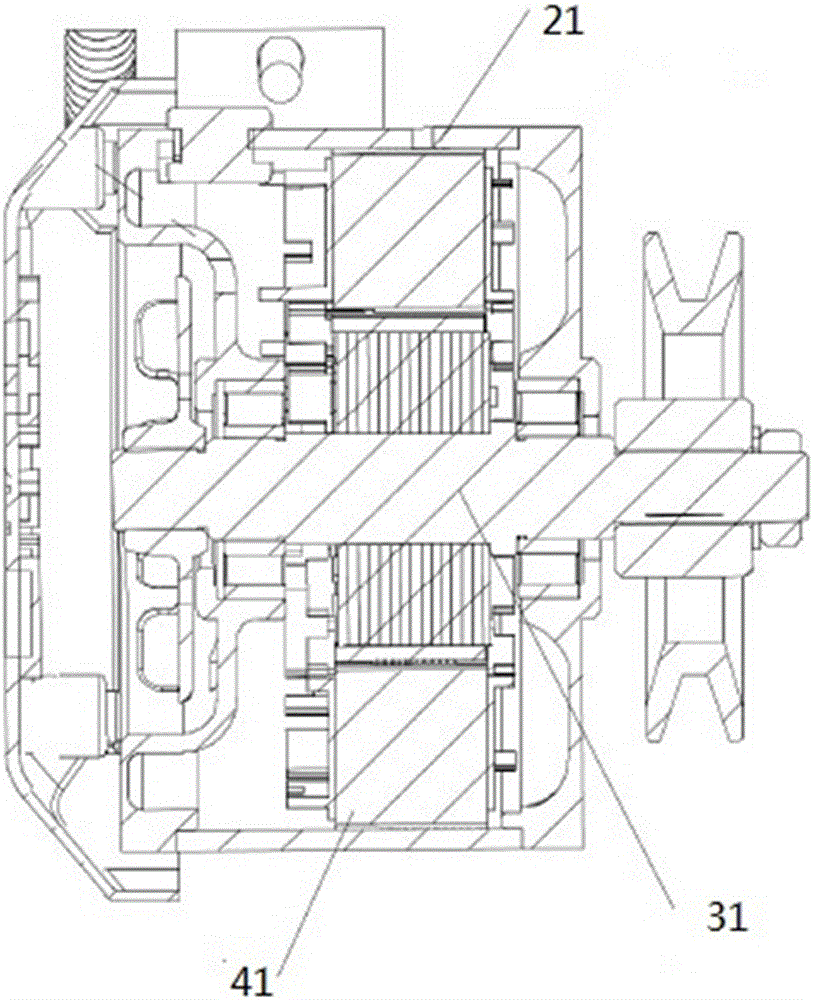

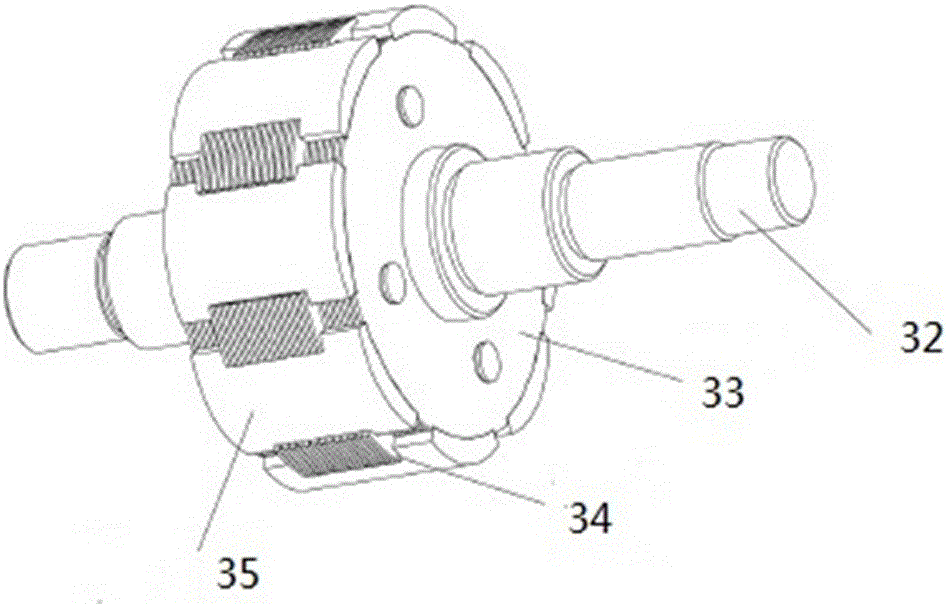

[0036] The energy-saving aerator used for cable production sewage treatment in this embodiment includes a working bridge installed above the sewage treatment tank, a bearing seat is installed on the working bridge, and the bearing seat is equipped with a drive shaft. The upper end of the shaft is covered with a driven gear, and the driven gear is driven to rotate by the first drive motor installed on the working bridge; the first drive motor includes a casing, a stator assembly and a rotor assembly, and the rotor assembly includes There is a motor shaft, which drives the driven gear to rotate; the lower end of the drive shaft is connected to a mounting plate, and the other end of the mounting plate is mounted with a second drive motor, and the second drive motor is equipped with a hollow shaft , the upper end of the hollow rotating shaft communicates with a compressed air source, the outer periphery of the hollow rotating shaft is provided with a transmission gear, the lower en...

Embodiment 2

[0038] The energy-saving aerator used for cable production sewage treatment in this embodiment includes a working bridge installed above the sewage treatment tank, a bearing seat is installed on the working bridge, and the bearing seat is equipped with a drive shaft. The upper end of the shaft is covered with a driven gear, and the driven gear is driven to rotate by the first drive motor installed on the working bridge; the first drive motor includes a casing, a stator assembly and a rotor assembly, and the rotor assembly includes There is a motor shaft, which drives the driven gear to rotate; the lower end of the drive shaft is connected to a mounting plate, and the other end of the mounting plate is mounted with a second drive motor, and the second drive motor is equipped with a hollow shaft , the upper end of the hollow rotating shaft communicates with a compressed air source, the outer periphery of the hollow rotating shaft is provided with a transmission gear, the lower en...

Embodiment 3

[0040] The energy-saving aerator used for cable production sewage treatment in this embodiment includes a working bridge installed above the sewage treatment tank, a bearing seat is installed on the working bridge, and the bearing seat is equipped with a drive shaft. The upper end of the shaft is covered with a driven gear, and the driven gear is driven to rotate by the first drive motor installed on the working bridge; the first drive motor includes a casing, a stator assembly and a rotor assembly, and the rotor assembly includes There is a motor shaft, which drives the driven gear to rotate; the lower end of the drive shaft is connected to a mounting plate, and the other end of the mounting plate is mounted with a second drive motor, and the second drive motor is equipped with a hollow shaft , the upper end of the hollow rotating shaft communicates with a compressed air source, the outer periphery of the hollow rotating shaft is provided with a transmission gear, the lower en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com