Preparation method and application of adjusting material for electric furnace white slag thermal refining treatment

A technology for tempering and calcareous materials, which is applied in the technical field of comprehensive utilization of electric furnace white slag, can solve the problems of restricting white slag utilization and no gelling activity, and achieve environmental protection, improve gelling activity, and optimize minerals composition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

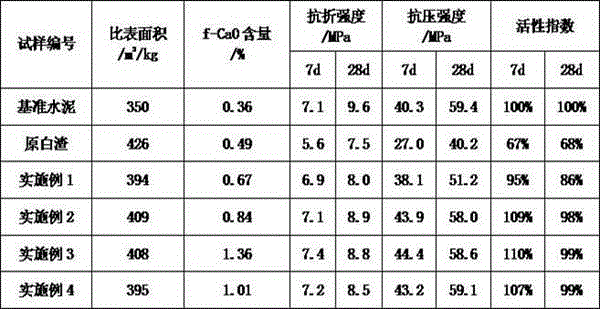

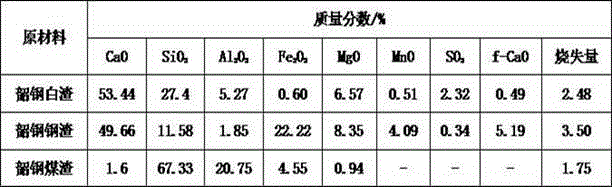

Embodiment 1

[0025] Select 33% converter steel slag, 17% coal slag, and 50% calcareous material (calculated as CaO) to prepare corresponding adjustment materials according to weight percentage, and then adjust the adjustment material and electric furnace white slag by weight percentage 46% adjustment material and 54% The white slag is mixed, and the mixture is calcined at a temperature of 1300°C, so that the adjustment material and the white slag undergo a chemical reaction; after the calcination is completed, the air cooling is used for rapid cooling; then the jaw crusher is used for crushing, and the ball mill is used for crushing Grinding until Blaine specific surface area is 350-450m 2 / kg, according to w (reference cement): w (white slag) = 70%: 30% to prepare cementitious materials, according to (GB / T 17671-1999) "Cement Mortar Strength Test Method (ISO Method)" Sand performance test.

Embodiment 2

[0026] Example 2: Select 29% converter steel slag, 14% coal slag, and 57% calcareous material (calculated as CaO) to prepare corresponding adjustment materials according to weight percentage, and then adjust the adjustment material and electric furnace white slag by weight percentage 50% The material is mixed with 50% white slag, and the mixture is calcined at 1300°C to cause a chemical reaction between the adjusted material and the white slag; after the calcination is completed, it is cooled quickly by air cooling; then it is crushed by a jaw crusher and then crushed by a ball mill. Grinding until Blaine specific surface area is 350-450m 2 / kg, according to w (reference cement): w (white slag) = 70%: 30% to prepare cementitious materials, according to (GB / T 17671-1999) "Cement Mortar Strength Test Method (ISO Method)" Sand performance test.

Embodiment 3

[0028] Select 31% converter steel slag, 15% coal slag, and 54% calcareous material (calculated as CaO) to prepare corresponding adjustment materials according to weight percentage, and then adjust the adjustment material and electric furnace white slag by weight percentage 48% adjustment material and 52% The white slag is mixed, and the mixture is calcined at 1300°C to make the adjustment material and the white slag chemically react; after the calcination is completed, it is cooled quickly by air cooling; then it is crushed by a jaw crusher and ground by a ball mill. Grind until Blaine specific surface area is 350-450m 2 / kg, according to w (reference cement): w (white slag) = 70%: 30% to prepare cementitious materials, according to (GB / T 17671-1999) "Cement Mortar Strength Test Method (ISO Method)" Sand performance test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com