A kind of granulation method of high-chromium type vanadium-titanium magnetite sintering mixture

A technology for vanadium titanomagnetite and sintering mixture is applied in the field of vanadium titanomagnetite to achieve the effects of improving air permeability, sintering speed, strength, yield and capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] After mixing 14.6 kilograms of high-chromium vanadium-titanium magnetite, 0.46 kilograms of quicklime and 0.62 kilograms of water, roll them into small balls on a disc pelletizer to obtain pellets with a particle size of 1 to 3 mm; The mass content of quicklime is 3%, and the mass content of water is 4%; the high-chromium vanadium-titanium magnetite used is 45% of the mass of the total high-chromium vanadium-titanium magnetite.

[0084] After mixing 17.9 kg of high chromium vanadium-titanium magnetite, 24 kg of returned ore, 4.34 kg of quicklime, 2.85 kg of coke powder, 4.98 kg of water and 15.6 kg of pellets, the cylinder pelletizer was used at 7.5 min and 24r / min under the conditions of pelletizing to obtain mixture particles; the returned ore is pre-wetted with water, wherein the mass content of water is 8%.

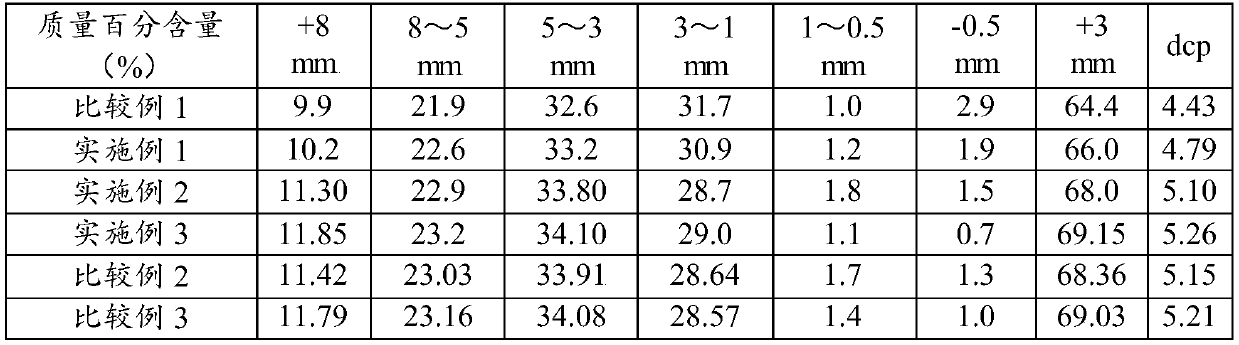

[0085] According to the method of Comparative Example 1, the particle size of the mixture particles prepared in Example 1 of the present invention is detected,...

Embodiment 2

[0087] The mixture particles are prepared according to the method described in Example 1; the difference from Example 1 is that the mass content of unslaked lime in the prepared pellets is 4%, and the mass content of moisture is 4.5%. The high-chromium vanadium-titanium magnetite accounts for 55% of the mass of the total high-chromium vanadium-titanium magnetite; the returned ore used is wetted with water in advance, and the mass content of water is 9%.

[0088] According to the method of Comparative Example 1, the particle size of the mixture particles prepared in Example 2 of the present invention is detected, and the test results are as shown in Table 1. As can be seen from Table 1, compared with Comparative Example 1, the obtained mixture particles prepared in Example 2 of the present invention The particle size content of mixture particles > 3mm increased by 3.6%, the powder < 0.5mm decreased by 1.4%, and the average particle size increased by 0.67mm.

Embodiment 3

[0090] Prepare the mixture particles according to the method described in Example 1; the difference from Example 1 is that the mass content of quicklime in the prepared pellets is 5%, and the mass content of moisture is 5%. The high-chromium vanadium-titanium magnetite accounts for 65% of the mass of the total high-chromium vanadium-titanium magnetite; the returned ore used is pre-wetted with water, and the mass content of water is 10%.

[0091] The particle size of the mixture particles prepared in Example 3 of the present invention is detected, and the detection results are shown in Table 1. It can be seen from Table 1 that compared with Comparative Example 1, the mixture particles prepared in Example 3 of the present invention>3mm The particle size content increased by 4.75%, the powder <0.5mm decreased by 2.2%, and the average particle size increased by 0.83mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com