Method and device for continuous preparation of vildagliptin by tubular reaction

A tubular reaction and tubular reactor technology, applied in the direction of organic chemistry, can solve the problems of long synthetic route, low yield, unfavorable large-scale production, and increased production cost, so as to increase the processing capacity, shorten the production cycle, The effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

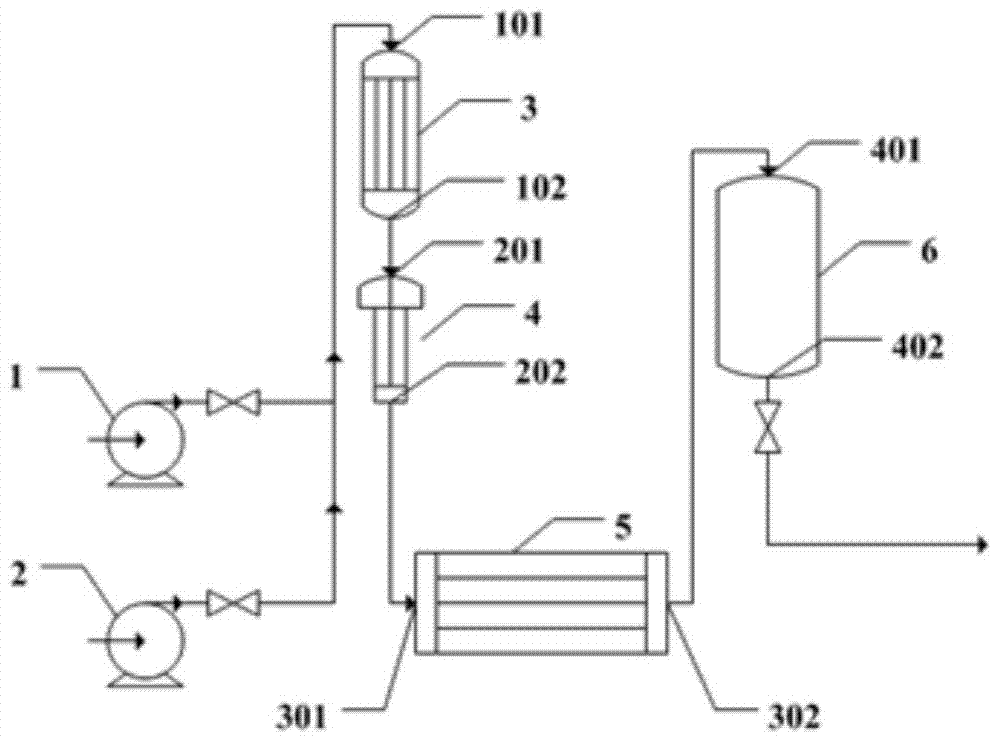

[0033] use figure 1 The device shown produces vildagliptin, and the structural parameters of the main equipment are as follows:

[0034] The pipe length of the tubular reactor 5 is 30m, the length of the preheater is 1.0m, and the volume of the reaction liquid receiving tank is 200L;

[0035] The steps are:

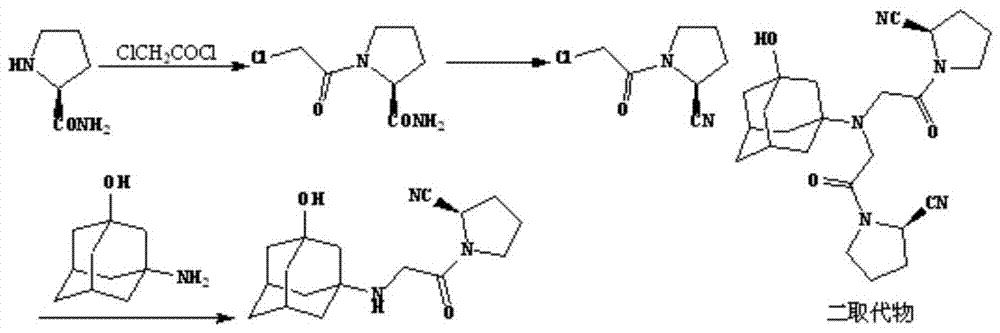

[0036] (1) 3-amino-1-adamantanol, 1-chloroacetyl-2-cyanopyrrolidine is dissolved in a mixed solution in a solvent, mixed with a suspension of alkali and a catalyst, and then preheated by a preheater;

[0037] (2) The preheated mixed solution enters the tubular reactor, the residence time of the material in the tubular reactor is 60min, and then the reaction solution discharged from the tubular reactor is collected and filtered, washed and purified to obtain the product.

[0038] The process parameters are as follows:

[0039] The temperature of the preheater is 70°C, the temperature of the tubular reactor is 70°C, and the flow rate of the material in the pipeline is 0....

Embodiment 2

[0043] use figure 1 The device shown produces vildagliptin, and the structural parameters of the main equipment are as follows:

[0044] The pipe length of the tubular reactor 5 is 100m, the length of the preheater is 1.0m, and the volume of the reaction liquid receiving tank is 200L;

[0045] The steps are:

[0046] (1) 3-amino-1-adamantanol, 1-chloroacetyl-2-cyanopyrrolidine is dissolved in a mixed solution in a solvent, mixed with a suspension of alkali and a catalyst, and then preheated by a preheater;

[0047] (2) The preheated mixed solution enters the tubular reactor, the residence time of the material in the tubular reactor is 100min, and then the reaction solution discharged from the tubular reactor is collected and filtered, washed and purified to obtain the product.

[0048] The process parameters are as follows:

[0049] The temperature of the preheater is 50°C, the temperature of the tubular reactor is 50°C, and the flow rate of the material in the pipeline is ...

Embodiment 3

[0053] use figure 1 The device shown produces vildagliptin, and the structural parameters of the main equipment are as follows:

[0054] The pipe length of the tubular reactor 5 is 80m, the length of the preheater is 1.0m, and the volume of the reaction liquid receiving tank is 200L;

[0055] The steps are:

[0056] (1) 3-amino-1-adamantanol, 1-chloroacetyl-2-cyanopyrrolidine is dissolved in a mixed solution in a solvent, mixed with a suspension of alkali and a catalyst, and then preheated by a preheater;

[0057] (2) The preheated mixed solution enters the tubular reactor, the residence time of the material in the tubular reactor is 150min, and then the reaction solution discharged from the tubular reactor is collected and filtered, washed and purified to obtain the product.

[0058] The process parameters are as follows:

[0059] The temperature of the preheater is 80°C, the temperature of the tubular reactor is 80°C, and the flow rate of the material in the pipeline is 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com