High-efficiency visible light antibacterial fresh-keeping plastic packaging material and preparation method thereof

A plastic packaging, visible light technology, used in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of affecting photocatalytic activity, poor chemical stability, no stability, etc., to achieve antibacterial preservation and removal of ethylene gas, affinity Good performance, stable and efficient visible light absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

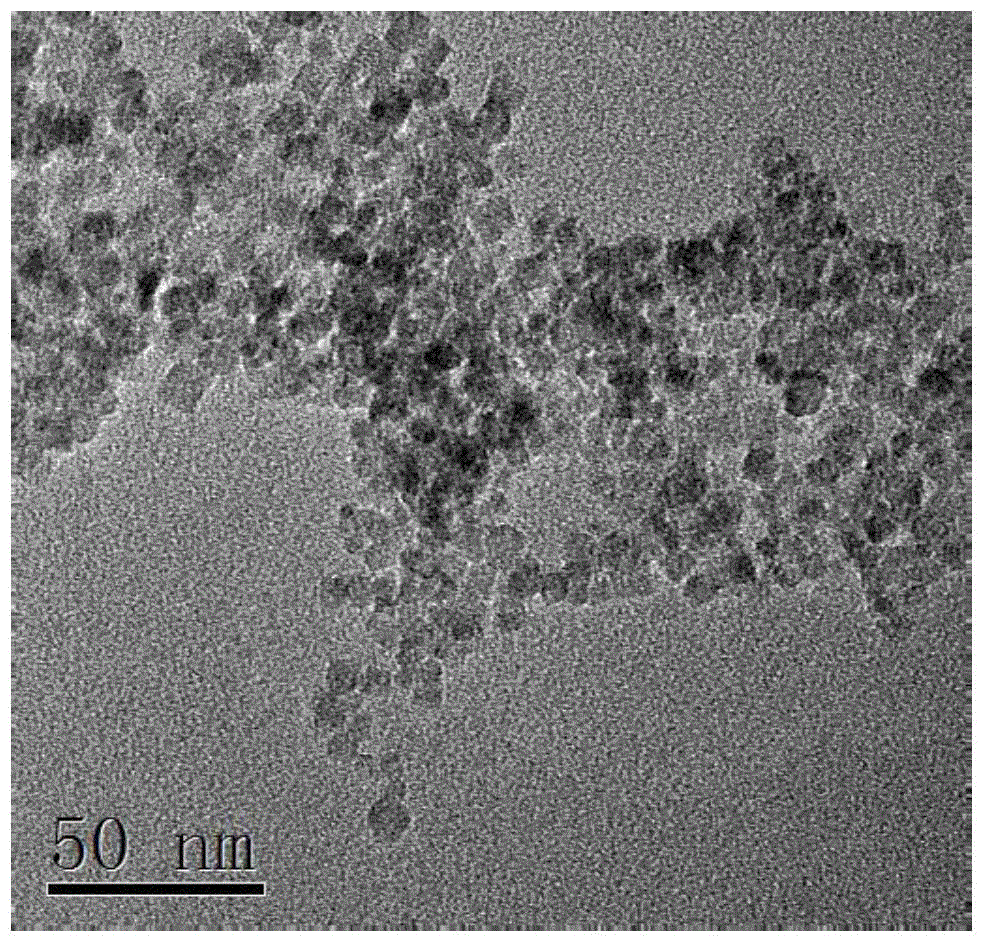

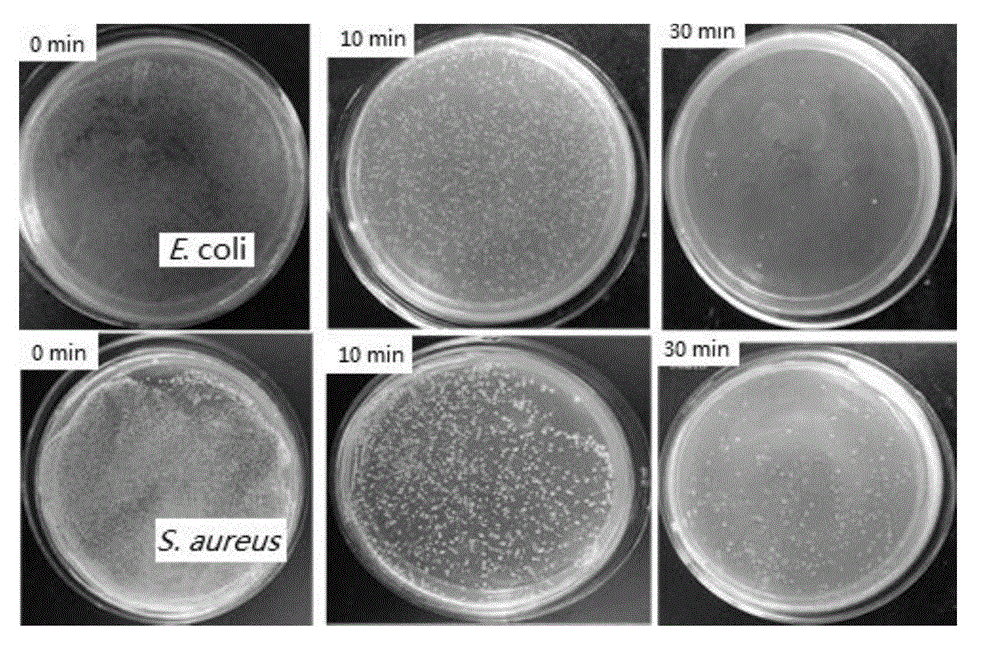

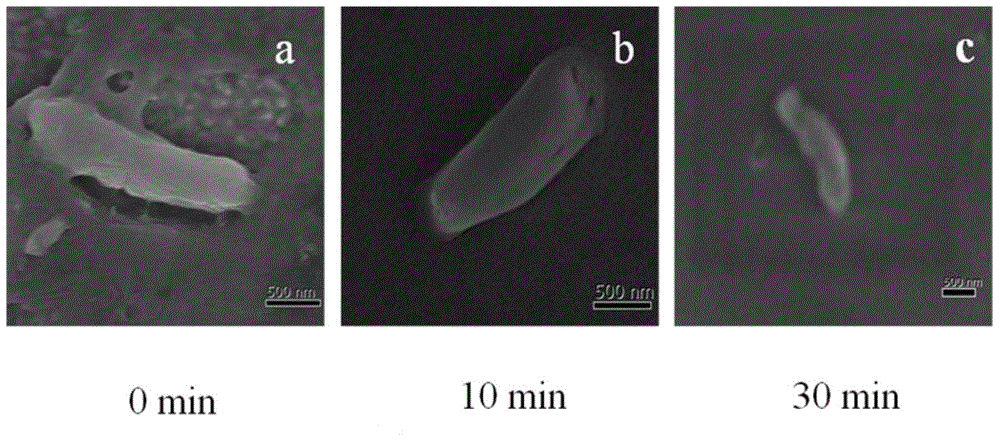

[0036] A high-efficiency visible light antibacterial and fresh-keeping plastic packaging material is a polyethylene packaging material with g-carbon nitride / titanium dioxide nanoparticles attached to one side. In the high-efficiency visible light antibacterial and fresh-keeping plastic packaging material, the mass fraction of g-carbon nitride / titanium dioxide nanoparticles is 1%, and the diameter of the g-carbon nitride / titanium dioxide nanoparticles is 5 nm.

Embodiment 2

[0038] A preparation method of the high-efficiency visible light antibacterial and fresh-keeping plastic packaging material described in Example 1, comprising the following steps:

[0039] (1) Preparation of g-carbon nitride nanoparticles: configure 30% melamine aqueous solution, and prepare g-carbon nitride nanoparticles in an autoclave. The preparation temperature in the autoclave is 180° C., and the preparation time is 8 hours;

[0040](2) Preparation of g-carbon nitride / titanium dioxide nanoparticles: Mix 15mL ethanol, 0.5mL water, 0.1mL nitric acid, and 0.0094g g-carbon nitride particles to prepare liquid A, mix 14mL ethanol, 2mL tetrabutyl titanate After mixing the esters to prepare liquid B, add liquid B dropwise to liquid A and stir for 0.5 hours at the same time, then add the mixture of liquid A and liquid B into the autoclave for reaction, the preparation temperature in the autoclave is 130 ° C, The preparation time is 8 hours. After the reaction is completed, it is ...

Embodiment 3

[0045] A preparation method of the high-efficiency visible light antibacterial and fresh-keeping plastic packaging material described in Example 1, comprising the following steps:

[0046] (1) Preparation of g-carbon nitride nanoparticles: prepare 50% melamine aqueous solution, prepare g-carbon nitride nanoparticles in an autoclave, the preparation temperature in the autoclave is 220° C., and the preparation time is 4 hours;

[0047] (2) Preparation of g-carbon nitride / titanium dioxide nanoparticles: Mix 20mL of ethanol, 1.5mL of water, 0.4mL of nitric acid, and 0.046g of g-carbon nitride particles to prepare liquid A, mix 18mL of ethanol, 6mL of tetratitanate After mixing the butyl esters to prepare liquid B, add liquid B dropwise to liquid A, and stir for 1 hour at the same time, then add the mixture of liquid A and liquid B into the autoclave for reaction, the preparation temperature in the autoclave is 180°C, The preparation time is 4 hours. After the reaction is completed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap