Method for underground replacement of erector main bearing of shield tunneling machine

A replacement method and technology for assembling machines, which are applied in the field of shield tunneling machines, can solve the problems of large construction volume and high cost, and achieve the effects of saving construction, saving project expenses and improving project progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In conjunction with the accompanying drawings, the present invention is described in detail, but the scope of protection of the present invention is not limited to the following embodiments, that is, all simple equivalent changes and modifications made with the patent scope of the present invention and the content of the specification are still patents of the present invention. covered.

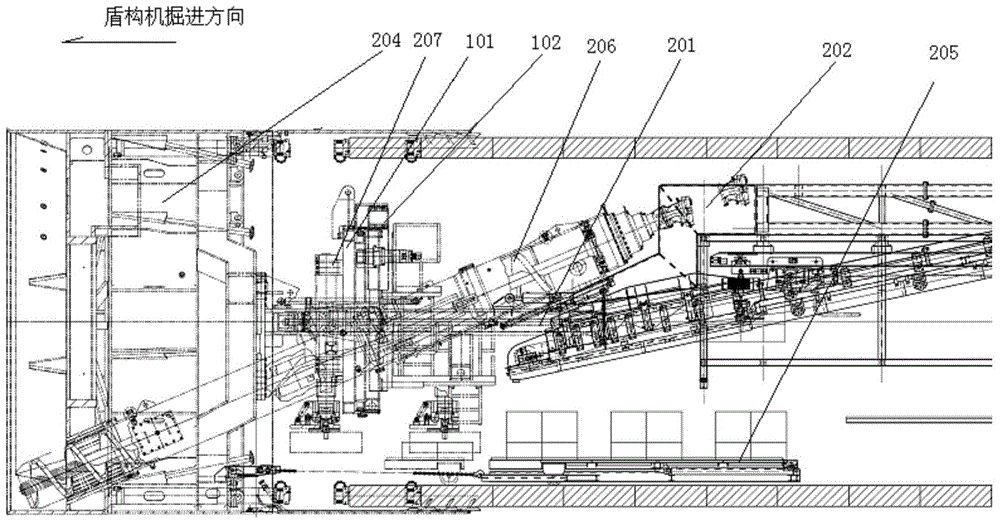

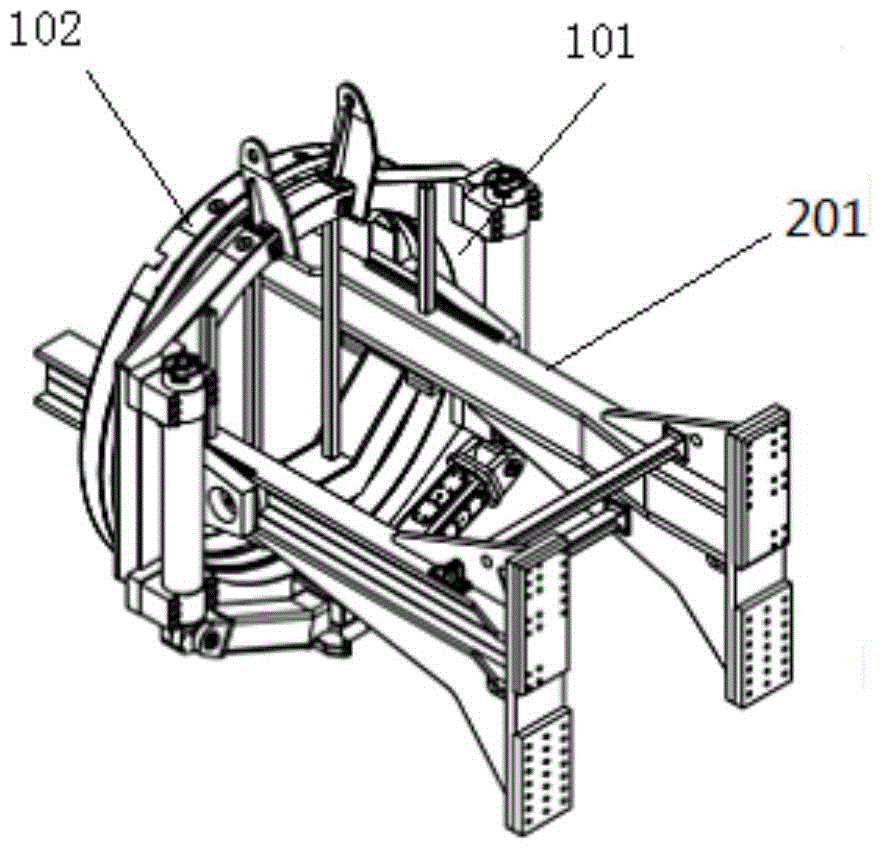

[0049] Depend on figure 1 It can be seen that the space inside the tunnel is narrow during the construction of the shield machine. For a tunnel of 5500mm, the diameter of the main bearing of the shield machine assembly machine can reach 3200mm, so there is not enough space for replacement underground. In view of this, the concrete implementation technical scheme of the present invention is as follows:

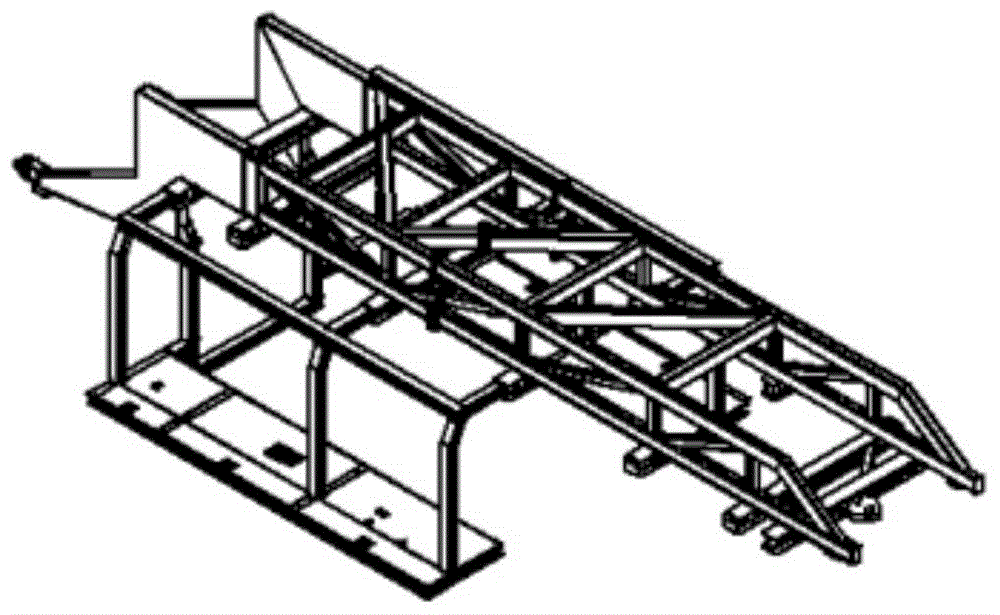

[0050] 1. Complete the preparations required before the hoisting trolley and bearing transport vehicle enter the site:

[0051] 1.1 remove the tablet feeder 205;

[0052] 1.2 Complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com