an engine mixer

A mixer and engine technology, applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of poor mixing effect, long mixer length, slow engine control response, etc., to achieve gas diffusion, mixer The effect of short length and fast control response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

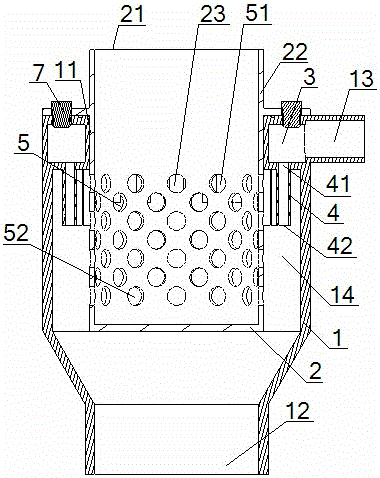

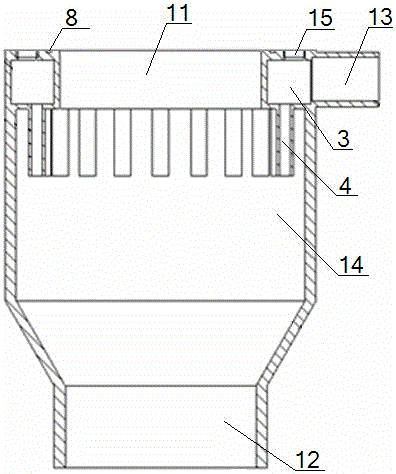

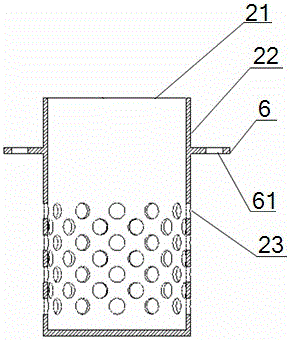

[0045] see figure 1 - image 3 , an engine mixer, including a mixer body 1, a mixer tube core 2, the mixer body 1 is a hollow structure with two ends open, including an air intake end 11, a mixed gas outlet end 12, and an inner cavity 14, the The inner wall of the air intake end 11 is inserted into the outer wall of the mixer tube core 2, and the outer wall of the air intake end 11 is connected with a natural gas intake pipe 13, and the air intake end 11 is provided with a sealing ring installation groove 8 and a second connecting hole 15 , and the inside of the intake end 11 is provided with an annular natural gas pressure stabilizing chamber 3 communicating with the natural gas inlet pipe 13 along its circumference. A plurality of natural gas injection pipes 4 evenly arranged on the periphery of the pipe core 2, the inlet end 41 and the outlet end 42 of the natural gas injection pipe 4 communicate with the annular natural gas pressure stabilizing chamber 3 and the inner cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com