Optical lens used for LED (light-emitting diode) lamp and LED lamp

A technology of LED lamps and optical lenses, which is applied in the field of optics, can solve the problems that a single LED cannot meet the requirements of light distribution and distribution of lamps, cannot meet the needs of actual use, and the light-emitting angle of LED lamps is small, and achieve low assembly process requirements, The effect of high practical significance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

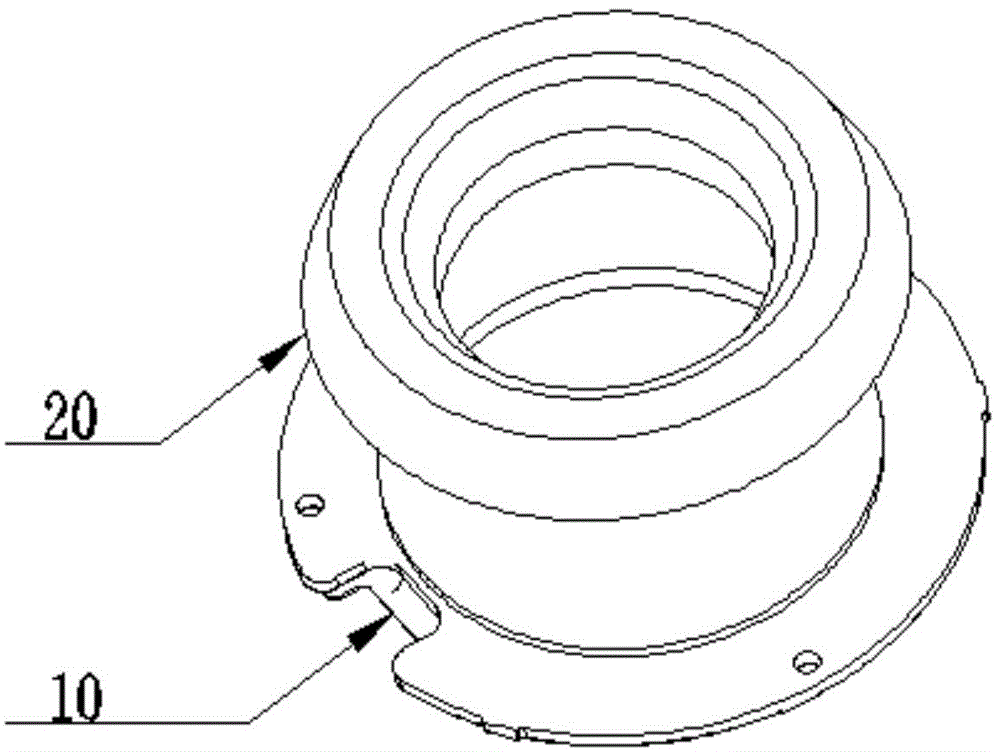

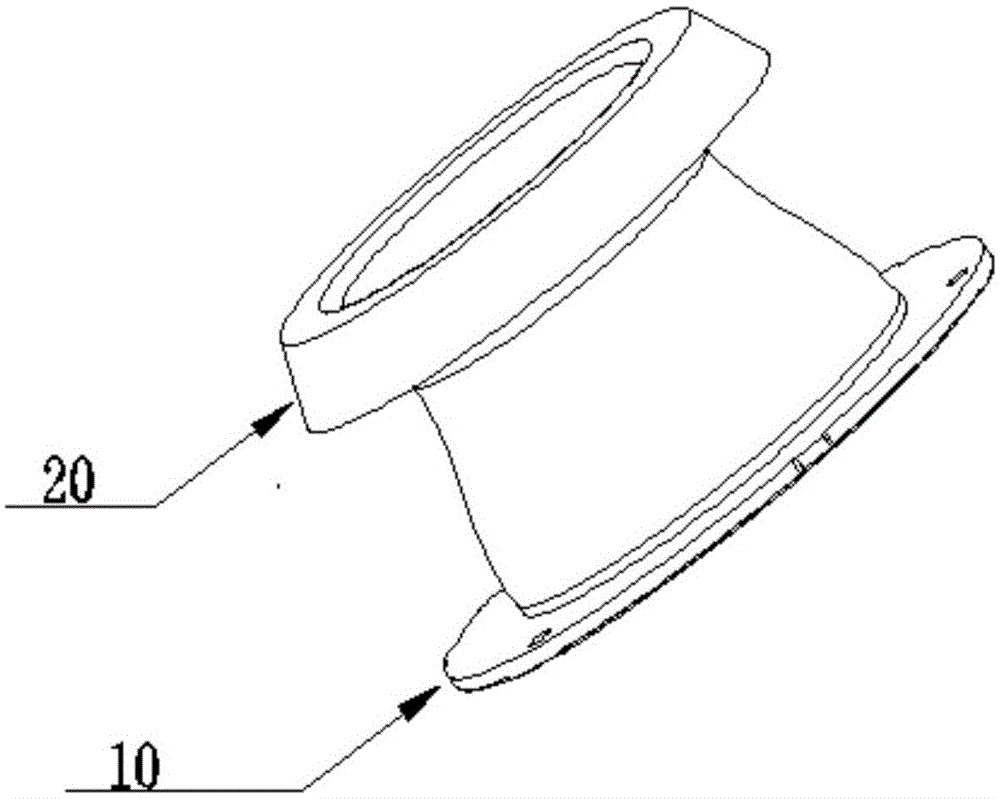

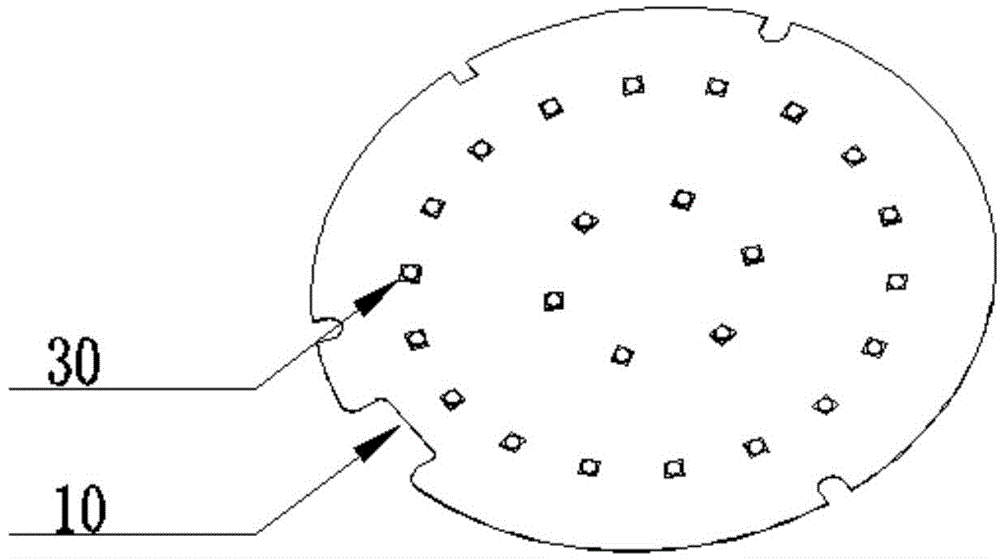

[0038] figure 1 with figure 2 A schematic structural diagram of an LED lamp according to a preferred embodiment of the present invention is shown, image 3 A schematic diagram of the structure of the light board, Figure 4 It is a top view of LED lamps. Figure 5 A cutaway view of the LED luminaire is given.

[0039] This embodiment provides an LED lamp, including an LED lamp bead 30 and an optical lens 20, the LED lamp bead 30 is fixed on the lamp board 10, and a plurality of LED lamp beads are arranged in the cavity of the optical lens 20, wherein the optical The lens 20 includes a light guide part 40 and a light emitting part 50. The light guide part 40 has a cavity for accommodating a plurality of LED lamp beads. The light guide part has a first surface 41 and a second surface 42 opposite to each other. The first surface 41 and the second surface The surface 42 can totally internally reflect and transmit the light emitted by the LED beads contained in the cavity to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rough | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com