Rapid measurement route planning method of sections of blades of aviation engine

An aero-engine, measurement path technology, applied in measurement devices, instruments, etc., can solve the problems of inability to realize real surface measurement, complex motion control, inability to take into account efficiency and accuracy, etc., to solve practical problems in factories, meet production needs, algorithms Simple and clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] A fast measurement path planning method for the section of an aeroengine blade, comprising the following steps:

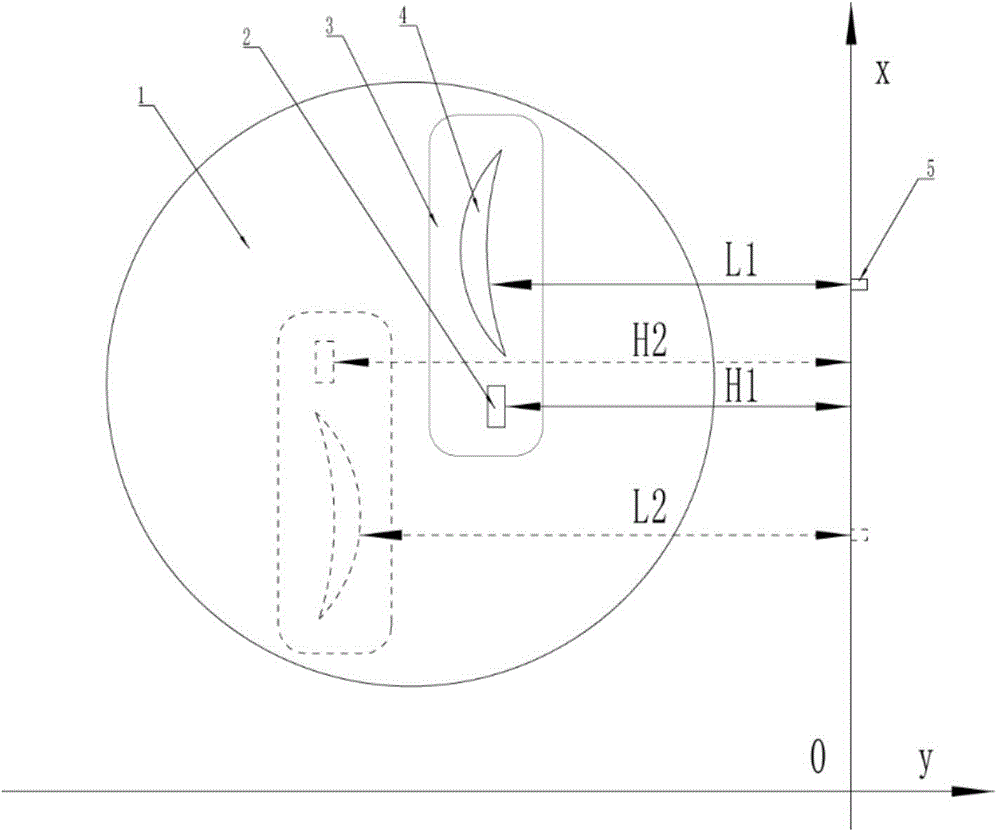

[0023] 1. Refer to the attached figure 1 , in the first step, the blade 4 to be tested is installed on the fixture 3, placed vertically on the horizontally rotatable measuring platform 1, and the standard gauge block 2 is installed on the fixture 3;

[0024] In the second step, when measuring, adjust the measuring sensor 5 clamped on the X-axis so that it can measure the distance H1 from the side of the standard gauge block 2 opposite to the X-axis, rotate the measuring platform 1180 degrees, and measure the standard gauge block 2 The distance H2 from the opposite side to the X axis, figure 1 The dotted line is the measurement state after rotating 180 degrees;

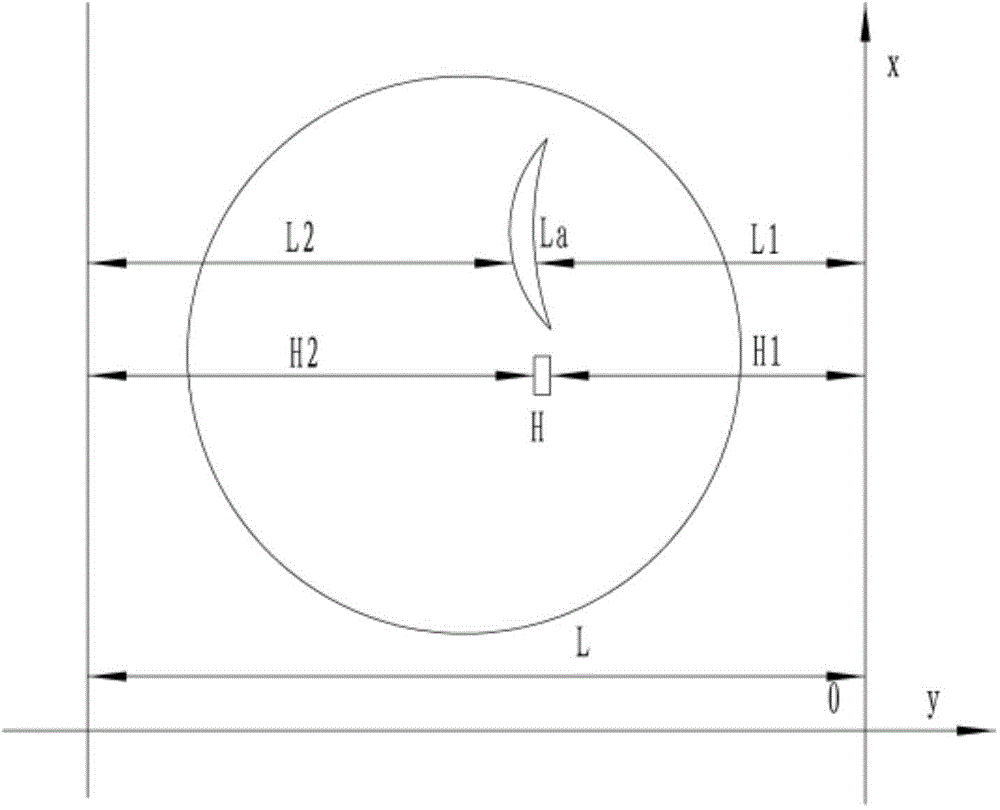

[0025] The third step is to adjust the measuring sensor 5 to the required characteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com