Device for performing freeze fracture on scanning electron microscope sample

A technology of freeze-fracture and scanning electron microscopy, which is applied in the field of pathological instruments, can solve problems such as the direction and force of blade knocking, frostbite of operators, inconvenience of natural section, etc., and achieve the effects of avoiding low-temperature frostbite, easy adjustment, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

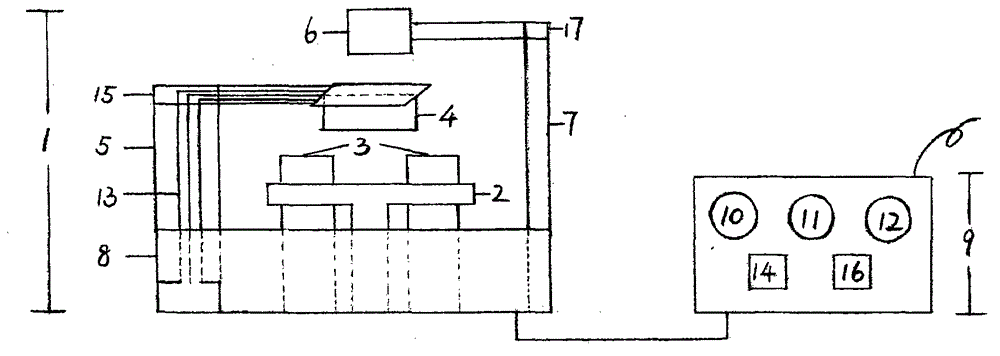

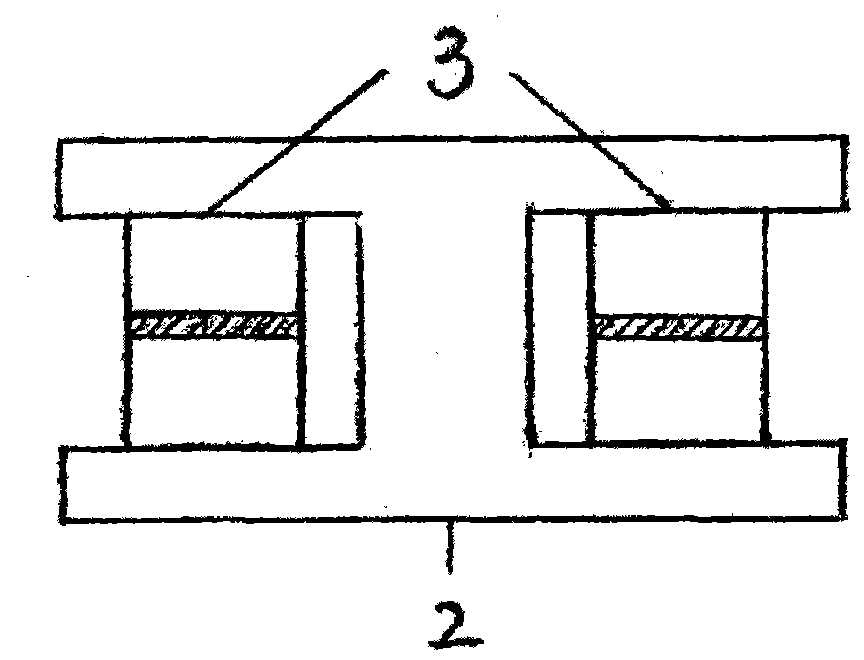

[0024] The present application provides a device for freezing and fracturing a scanning electron microscope sample. The device comprises a freeze fracture device main body (1) and a main control console (9), the freeze fracture device main body (1) is connected with the main console (9), and the main control console (9) is connected with an external power supply to the freeze fracture device main body (1) Power supply, the main body (1) of the freeze fracture device includes the sample stage (2), the fixing devices (3) on both sides of the sample stage (2), the liquid nitrogen tank (8) under the sample stage, the cutting knife (4), The cutter (4) is connected with the liquid nitrogen tank (8) through the cutter arm (5), and the cutter arm (5) has a liquid nitrogen circulation device (13), a first reset device (15), a knocking device ( 6), the knocking device (6) is connected with the liquid nitrogen tank (8) through the knocking device arm (7), and there is a second reset devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com