Mold for detecting mold flow marks of epoxy molding plastic

A technology of epoxy molding compounds and molds, which is applied in the direction of material inspection products, etc., can solve the problems of labor and framework costs, high simulation test costs, and inconspicuous verification effects, etc., to shorten the verification cycle, reduce the cost of consumables, and reduce consumables Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

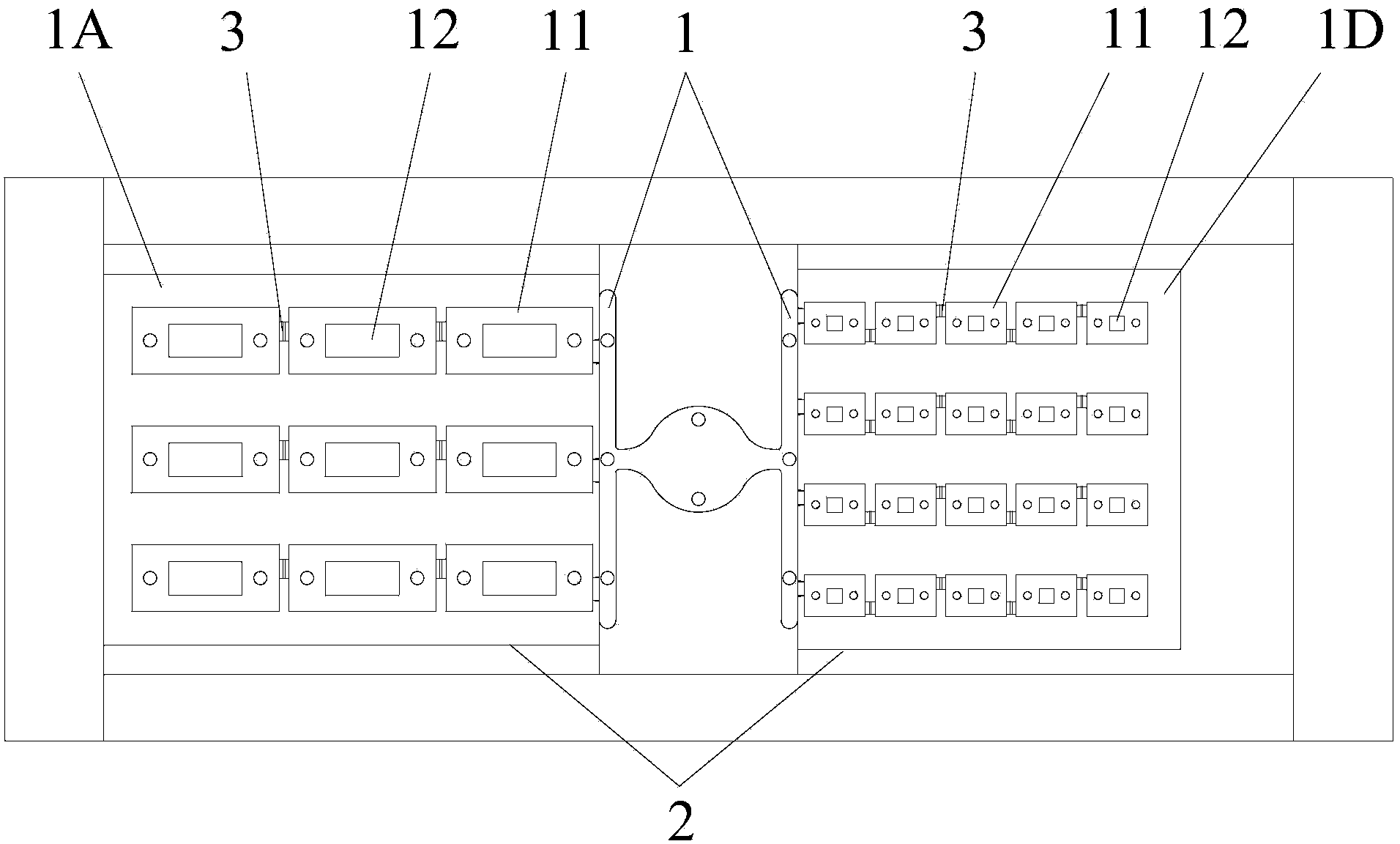

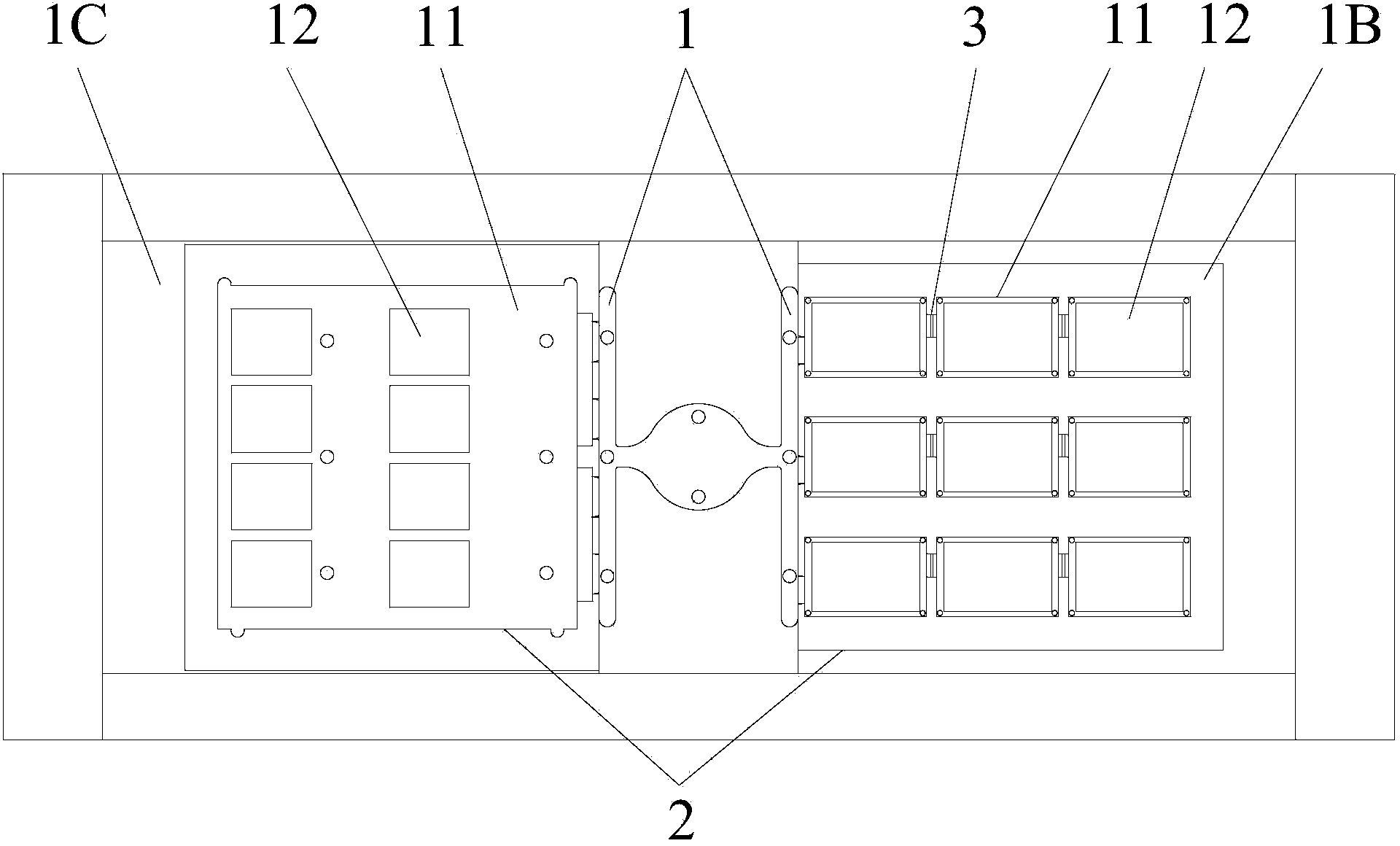

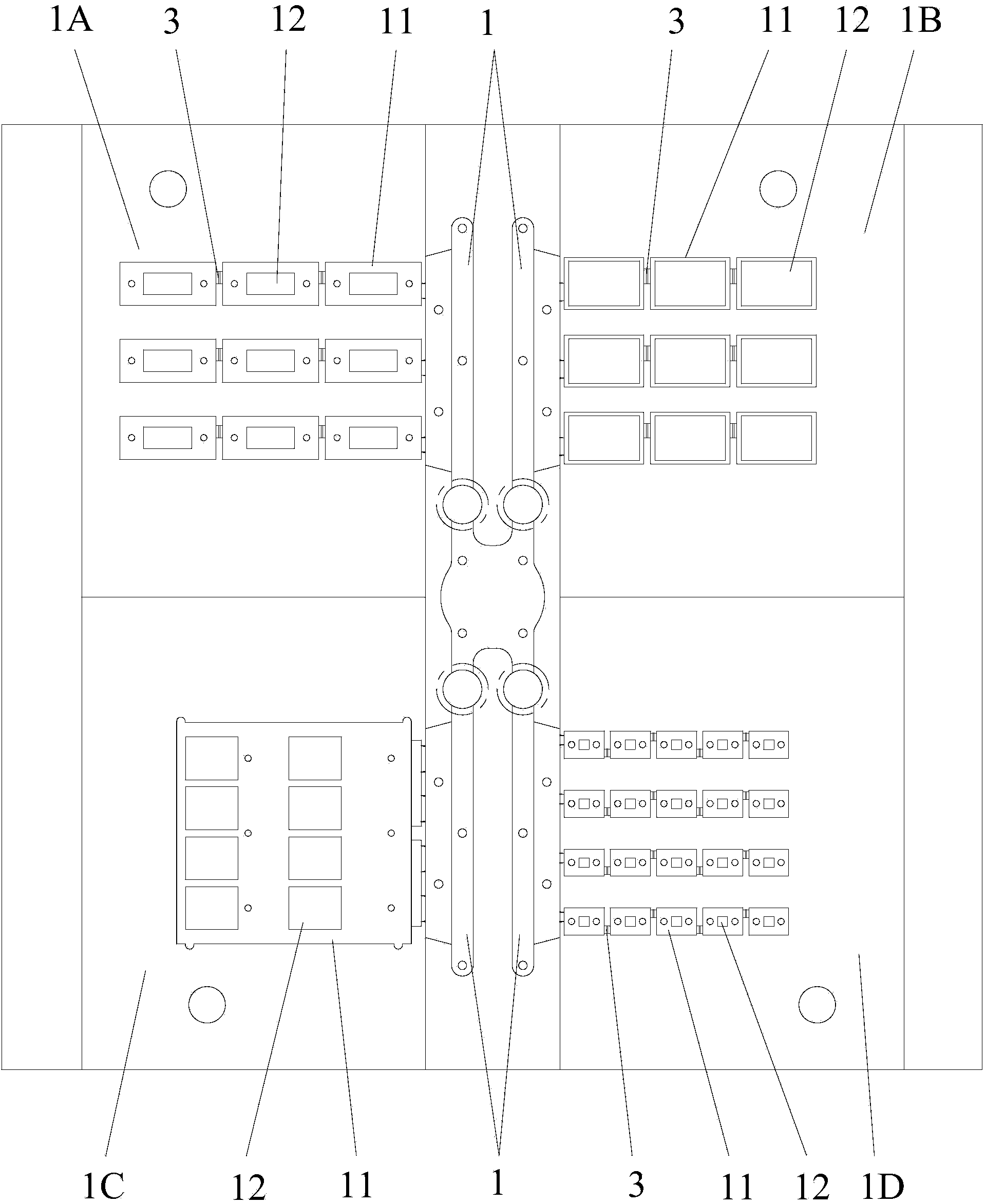

[0019] Combine figure 1 , figure 2 with image 3 As shown, a mold for detecting mold flow marks of epoxy molding compound includes a mold body; the mold body includes an upper module and a lower module; the upper module is provided with an upper module insert; the The lower module is provided with a lower module insert for use with the upper module insert; the lower module insert is composed of a glue inlet channel 1 located in the middle position and a row cavity portion 2 located on both sides; the row cavity portion 2 It communicates with the glue inlet channel 1 through the flow channel 3; the row cavity portion 1 is composed of one or more row cavities 11; the row cavity 11 has a groove structure; the bottom surface of the row cavity 11 is provided with an analog chip 12; The surface of the analog chip 12 is provided with a chrome-plated bright surface layer; the row cavity 11 except for the analog chip 12 is provided with a matte surface material layer on the other surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com