Location grid rack provided with streamline low pressure drop runner, and fuel assembly

A positioning grid, low pressure drop technology, applied in the direction of reactor fuel elements, nuclear power generation, climate sustainability, etc., can solve the problems of increased fluid pressure loss, unfavorable pressure maintenance, fuel rod scratches, etc., to avoid vibration, Effect of fluid pressure drop and pressure loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

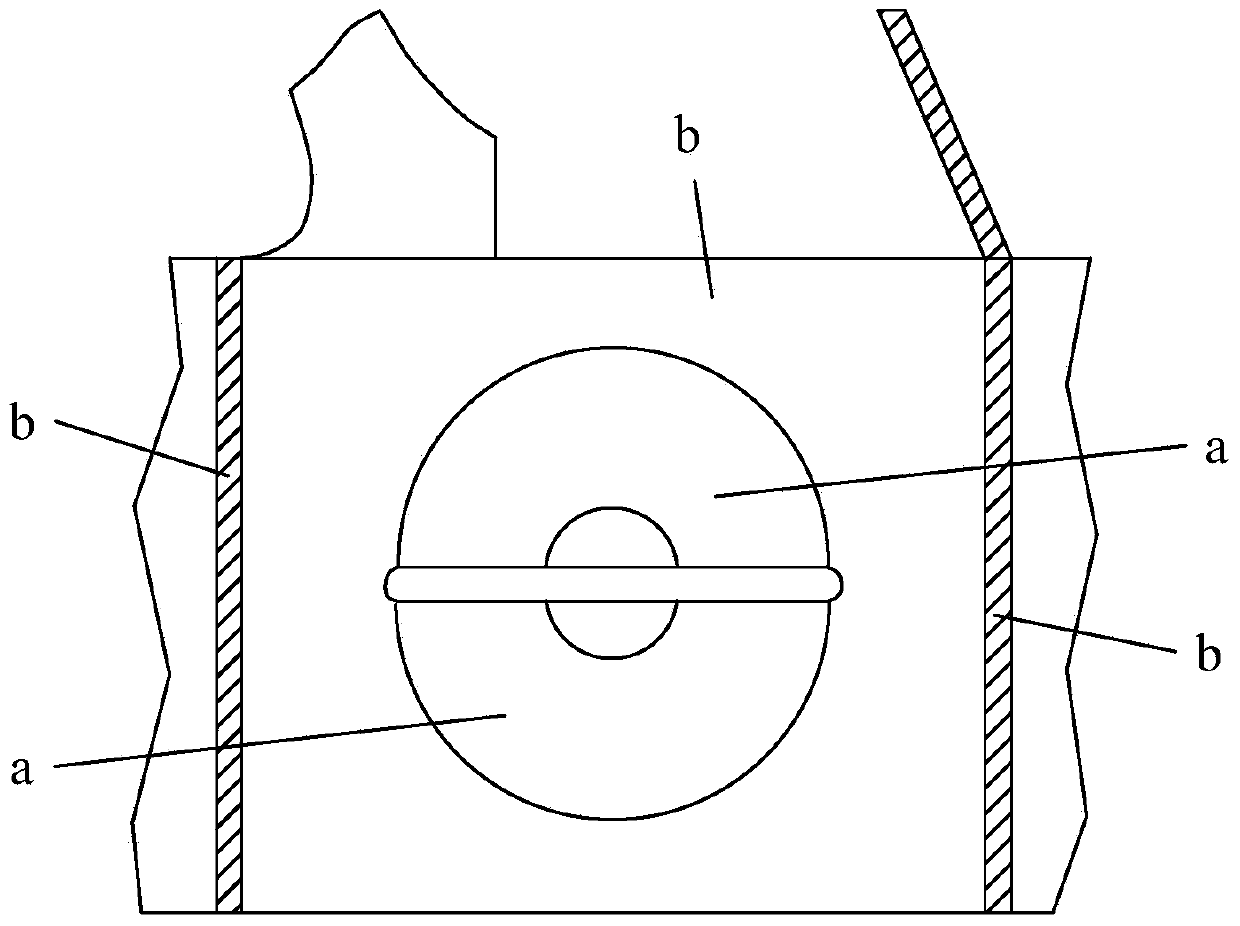

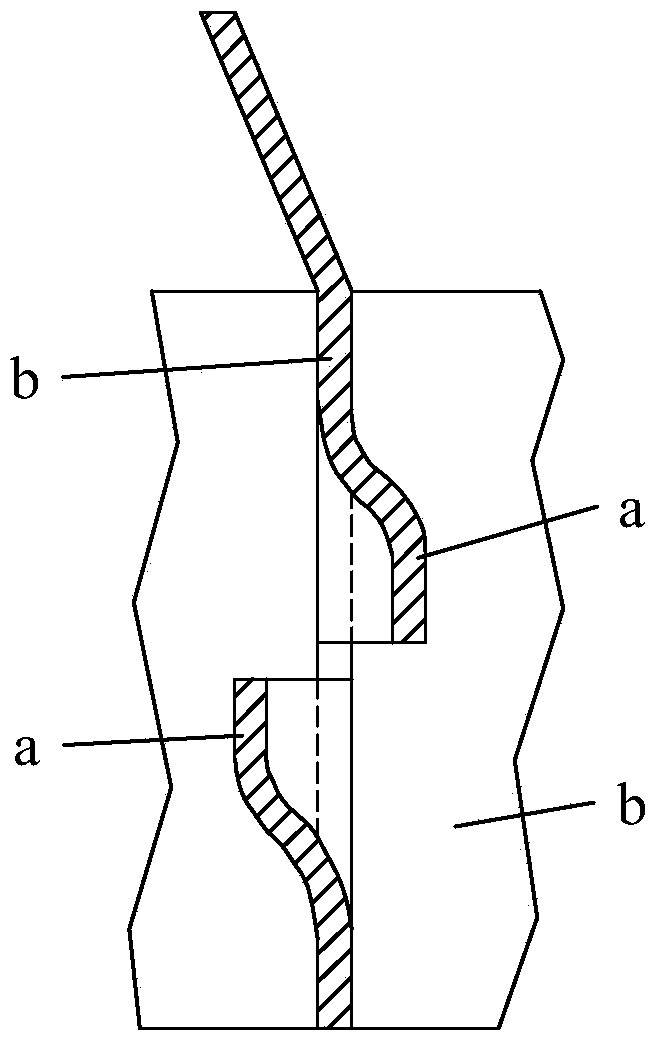

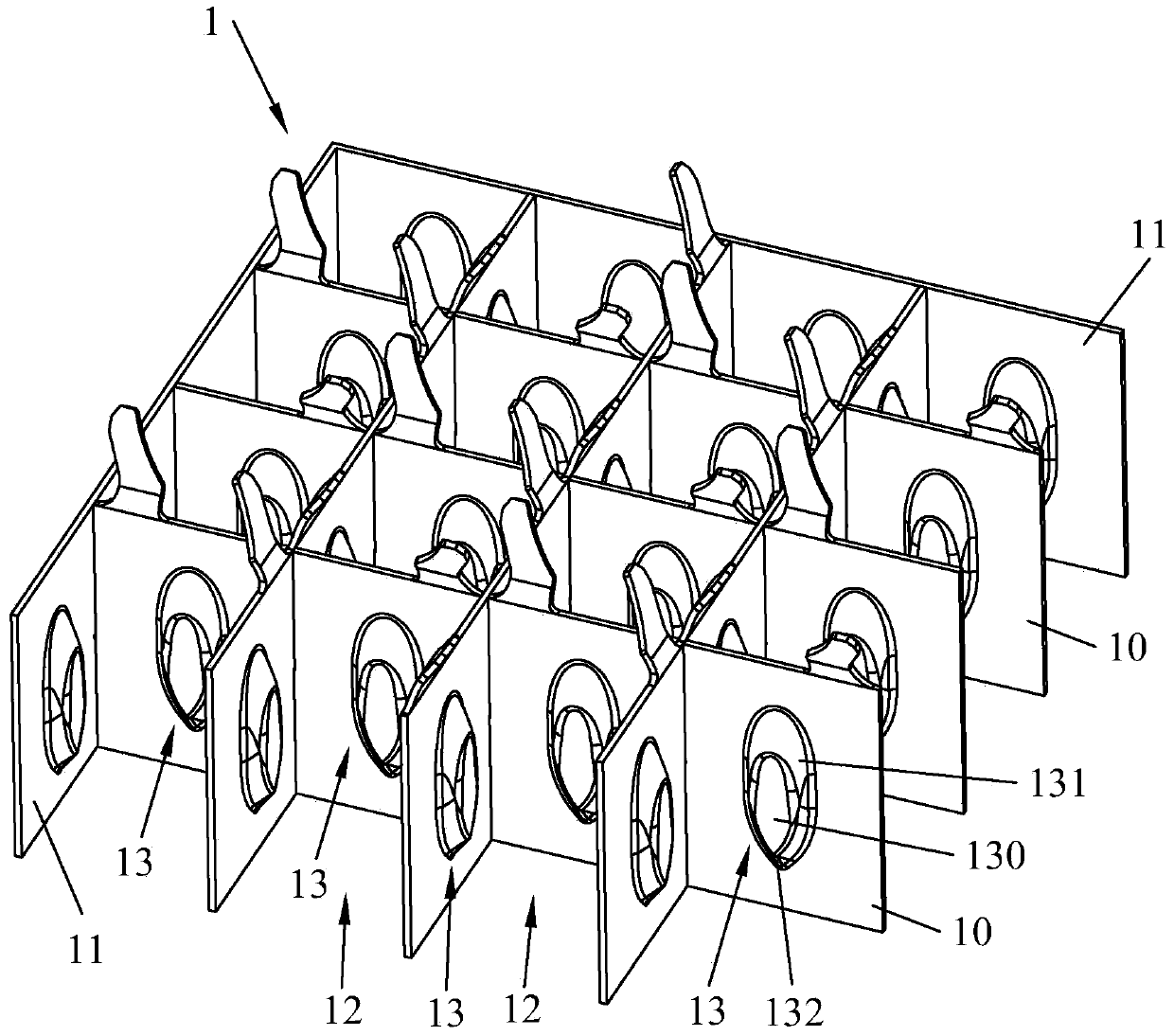

[0028] Such as Figures 3 to 5 Shown is a first embodiment of the invention. In this embodiment, a spacer grid 1 with a streamlined low-pressure drop channel is provided, the spacer grid 1 includes a plurality of inner strips 10 and outer strips 11, and a plurality of inner strips 10 intersect each other to form a The grid structure forms a plurality of hollow grid units 12 , the outer strips 11 surround the grid structure and are fixed to the inner strips 10 . The inner strip 10 is fixed with a rigid protrusion 13 protruding inwardly of the grid unit 12, and the rigid protrusion 13 includes a plane 130 in contact with the fuel rod 4 and is closed and smoothly connected to the plane 130 and the plane 130. On the side surfaces 131 between the inner strips 10 , the lowermost ends of the side surfaces 131 form downward corners 132 , and the grid uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com