Improved 7XXX aluminum alloys, and methods for producing the same

A technology of aluminum alloy and aluminum alloy sheet, which is applied in transportation and packaging, superstructure, vehicle parts, etc., and can solve problems such as improving aluminum alloy and increasing alloy strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

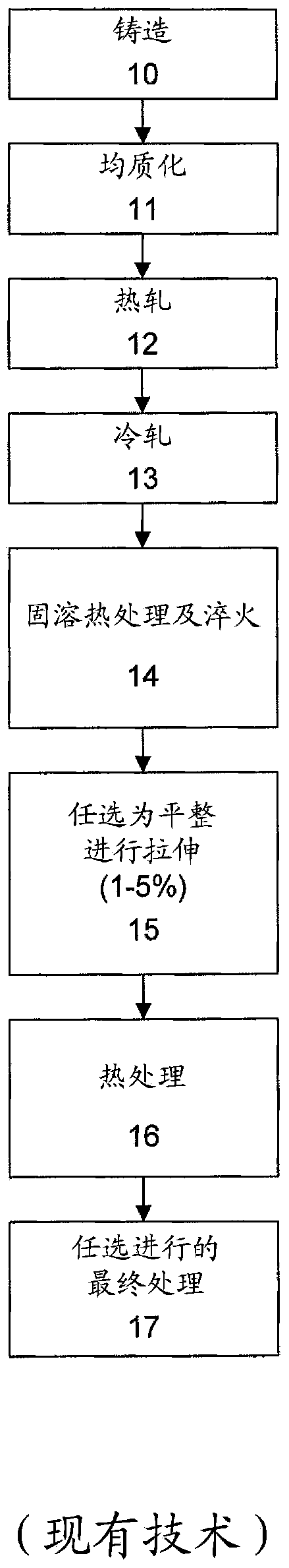

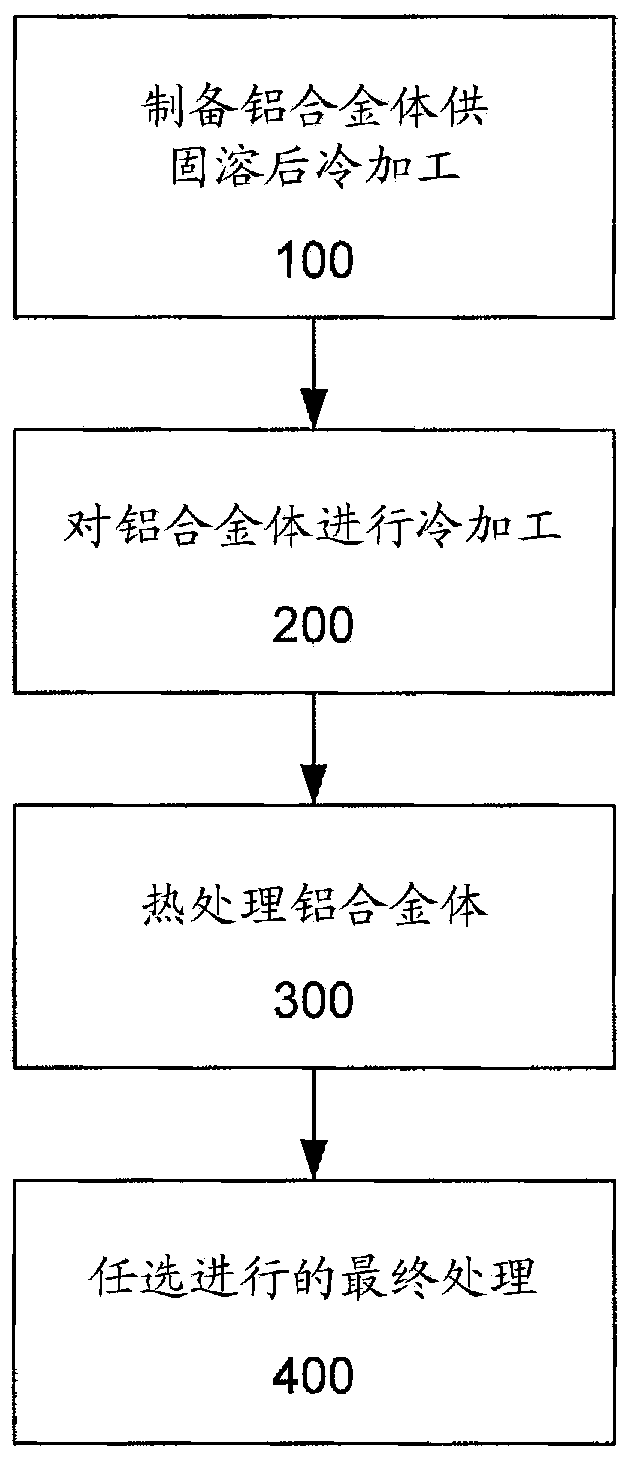

Method used

Image

Examples

example 1

[0494] A first 7xxx aluminum alloy having the composition listed in Table 3 below was cast, homogenized and hot rolled into plates / sheets having intermediate gauges of approximately 0.53 inches, 0.32 inches, 0.16 inches (x2) and 0.106 inches, respectively . One of the 0.16 inch samples (the control) was then cold rolled to about 0.08 inch final sheet gauge, solution heat treated by soaking at about 885°F for about 30 minutes, followed by cold water quenching and subsequent stretching for 1- 2% for stress relief. The control was naturally aged for approximately four days, followed by heat treatment to a T6 type condition.

[0495] The others of the samples were first solution heat treated (in the same process) and then cold rolled to 0.08 inch final sheet gauge, representing about 85%, 75%, 50% and 25% cold work, respectively.

[0496] Table 3 - Composition of the first 7xxx aluminum alloys (all values are expressed in weight percent)

[0497] Si

Fe

Cu ...

example 2

[0519] Additional mechanical properties of the first 7xxx aluminum alloys were tested. Specifically, the first 7xxx aluminum alloys were tested for longitudinal (L) and long transverse (LT) strength, elongation, and fracture toughness properties, the results of which are provided in Tables 11-12 below. These results indicate that 7xxx aluminum alloy bodies can achieve similar strength and elongation properties in the L and LT directions.

[0520] Table 11 - Strength and elongation properties of the first 7xxx aluminum alloys

[0521]

[0522]

[0523] Table 12 - Toughness properties of the first 7xxx aluminum alloys

[0524]

[0525] Fracture toughness test according to ASTM test standard ASTM E561 and ASTM B646 (for K app and K R25 ) and E399 and B645 (K IC / K Q )conduct. Use the middle crack fracture sample (M(T)) for K app Measurement. The sample width (W) is 6.3 inches, the thickness (B) is 0.08 inches, and the initial crack length (2a 0 ) is 1.573 in...

example 3

[0538] Two additional 7xxx aluminum alloy bodies were prepared according to Example 1 . Both are known Russian alloys. One alloy is a copper-free 7xxx aluminum alloy (alloy 1980) and the other alloy is a low-copper 7xxx aluminum alloy (alloy 1953). The compositions of these aluminum alloys are provided in Tables 16-17 below. The alloy contains the listed ingredients, with the balance being aluminum and not greater than 0.05% by weight of each other element, and the sum of these other elements is not greater than 0.15% by weight.

[0539] Table 16 - Composition of the second 7xxx alloys (all values are expressed in weight percent)

[0540] 1953

[0541] Table 17 - Composition of third 7xxx alloys (all values are expressed in weight percent)

[0542] 1980

[0543] The results of Example 3 illustrate that the cold working step and heat treatment step must be properly accomplished to achieve improved properties such as strength. As shown in Figures ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com