Liquid tea and application thereof

A liquid and tea liquid technology, applied in the direction of tea extraction, can solve the problems of incomplete extraction of natural color and fragrance components, complex extraction and preservation technology, easy loss of fragrance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

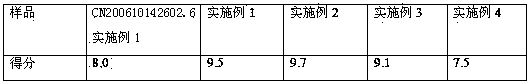

Examples

Embodiment 1

[0043] The tea leaves are slightly dried until the water content is 6%, and rinsed in ice water at 9°C while hot. The purpose of rinsing is to wash off the dust on the tea leaves. The extracted liquid tea is more hygienic. Rinse the tea leaves with ice water. Nutrition and aroma will not be lost.

[0044]Put the tea raw materials that have been rinsed into a grinder to grind them into a paste, and then soak the tea paste to obtain tea liquid. The soaking method is: put the paste tea raw materials into a stainless steel bucket, add mineral water, or meet the national drinking conditions. Water standard drinking water, the weight ratio of the tea paste raw material and mineral water is: 1:1, the soaking water temperature is 90°C, the soaking time is 8 hours, the soaking continuous temperature is 82°C, and it is stirred every 2 hours.

[0045] Filter and extract the soaked tea liquid, and filter through a sieve with a mesh size of 300 or more to obtain liquid tea. The filtered li...

Embodiment 2

[0048] The primary black tea is slightly dried until the water content is 8%, and rinsed in ice water at 5 degrees while it is hot. The purpose of rinsing is to wash off the dust on the tea leaves. The extracted liquid tea is more hygienic. The nutrition and aroma of the tea will not be lost by rinsing with water.

[0049] Put the tea raw materials that have been rinsed into a grinder to grind them into a paste, and then soak the black tea paste to obtain tea liquid. The soaking method is: put the paste black tea raw materials into a stainless steel bucket, add mineral water (or meet the national drinking Water standard drinking water), the weight ratio of black tea paste raw material and mineral water is: 1:3, the soaking water temperature is 90 degrees, the soaking time is 8 hours, the soaking temperature continues at 80 degrees, the soaking environment temperature is 30-35 degrees, every Stir once every 2 hours.

[0050] Filter and extract the soaked tea liquid, and filter...

Embodiment 3

[0054] The primary black tea is slightly dried until the water content is 6%, and rinsed in ice water at 5 degrees while it is hot. The purpose of rinsing is to wash off the dust on the tea leaves. The extracted liquid tea is more hygienic. The nutrition and aroma of the tea will not be lost by rinsing with water.

[0055] Put the tea raw materials that have been rinsed into a grinder to grind them into a paste, and then soak the black tea paste to obtain tea liquid. The soaking method is: put the paste black tea raw materials into a stainless steel bucket, add mineral water (or meet the national drinking Water standard drinking water), the weight ratio of black tea paste raw material and mineral water is: 1:1.8, soaking water temperature is 95 degrees, soaking time is 12 hours, soaking environment temperature is 30-35 degrees, soaking temperature is continued at 90 degrees, every Stir once every 2 hours.

[0056] Filter and extract the soaked tea liquid, and filter it with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com