Real-time non-contact measuring and compensating device of local deformation quantity

A non-contact measurement and local deformation technology, applied in the direction of measuring/indicating equipment, other manufacturing equipment/tools, metal processing machinery parts, etc., can solve problems such as inconsistent milling depth, increased deformation, and fluctuations in workpiece deformation, and achieve no error accumulation , reduce impact, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention will be clearly and completely described below in combination with specific embodiments and accompanying drawings.

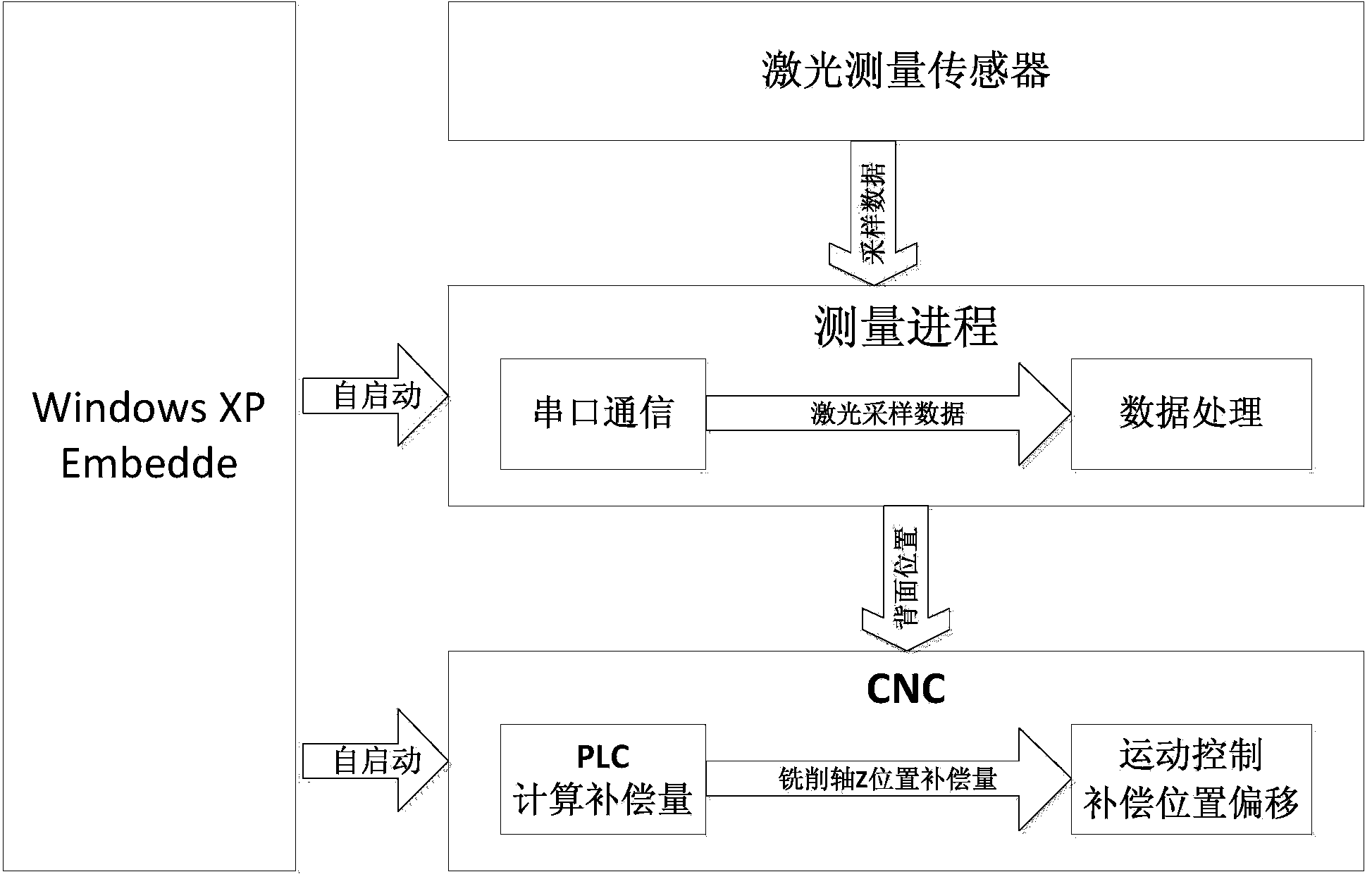

[0015] Such as figure 1 As shown, a real-time non-contact measurement and compensation device for local deformation is characterized in that:

[0016] Including CNC system, real-time laser measurement module and feed axis position compensation module; wherein the positive direction of the laser measurement axis and the forward direction of the target compensation axis are on the same axis but opposite to each other; the target compensation axis is the milling axis equipped with tools;

[0017] (1) Real-time laser measurement module, including laser displacement sensor, computer serial port, and data analysis module;

[0018] Real-time sampling and measurement of the position of the back of the milling point of the workpiece during the milling process by the laser displacement sensor, the position data is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com