Arrangement of a wheel hub connected to a constant velocity joint provided with a seal device

A constant velocity joint and sealing device technology, applied in the direction of the hub, engine seal, wheel, etc., can solve the problem of not always strong enough magnetic signal, reducing radial extension, and complicated installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

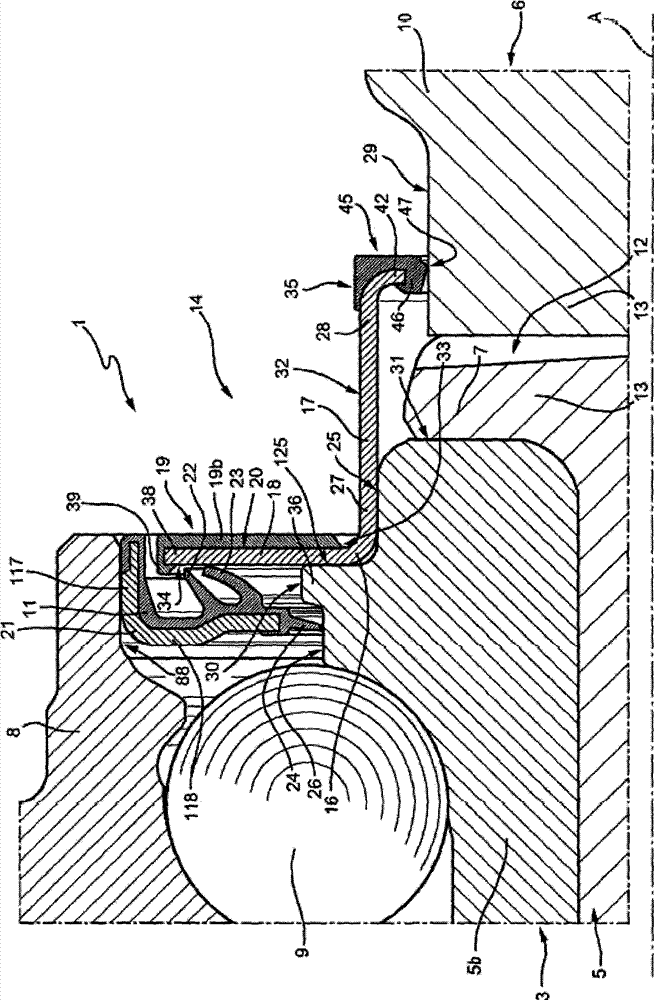

[0017] With reference to the above figures, number 1 designates the whole of the sealing device for the hub assembly 3, the inner ring 5 of which is operatively associated with the constant velocity joint 6 to rotate therewith, which is known and thus convenient For sake of illustration only part is shown. The hub assembly 3 further comprises: an outer ring 8 mounted coaxially and concentrically with the ring 5 , radially outside the ring 5 ; and a plurality of rolling bodies 9 interposed between the rings 5 and 8 . The inner ring 5 comprises a ring 5b (insertion ring or "SIR") made as a separate element, axially blocked by a bead 7 and externally delimited by an outer cylindrical side surface 26; Meanwhile, the constant velocity joint 6 includes an outer ring 10 (the only part of the constant velocity joint 6 shown in the drawings), which has an outer cylindrical side surface 29 and is generally arranged substantially at the same level as the inner ring 5. The shaft also h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com