Portal crane holographic detection method and safety monitoring platform

The technology of a portal crane and detection method is applied in the directions of safety devices, transportation and packaging, load hanging components, etc., which can solve the problems of not being able to meet people's requirements and not being able to understand the operating status of the crane in real time, so as to save manpower, The effect of avoiding accidents and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

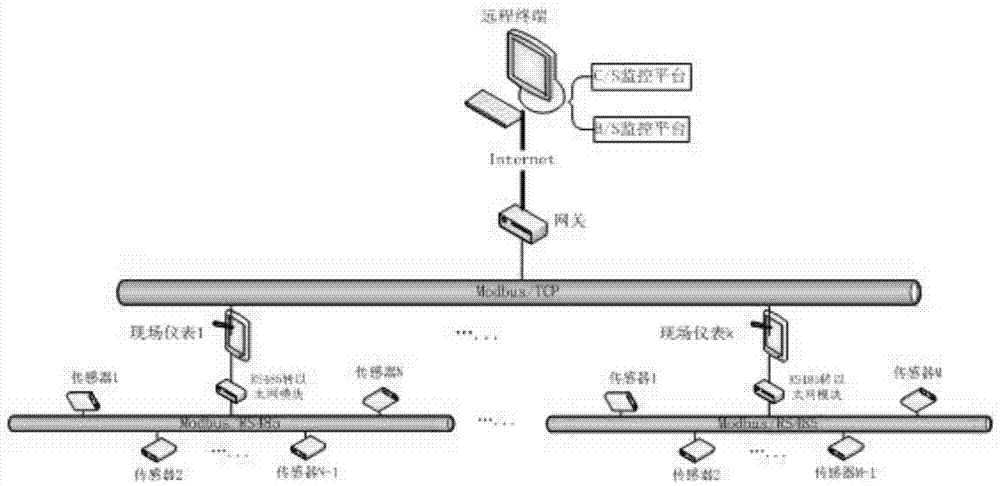

[0025] The holographic detection method of the portal crane is mainly divided into two aspects: quantitative detection and qualitative detection. The quantitative detection items include the detection of lifting weight, the detection of the amplitude, the detection of the safety distance of the same or different track running mechanism, the detection of working time, and the temperature of lubricating oil. Detection, wind speed detection, environmental factor detection; qualitative detection items include lifting / lowering limit detection, lifting brake safety limit detection, rotation angle limit detection, power supply cable reel safety limit detection.

[0026] like Figure 4 As shown, the measurement of the lifting weight is the measurement of the tension of the rope. Install an absolute encoder at the shaft end of the drum of the crane lifting mechanism, detect the absolute angle of the drum through the absolute encoder, measure the length of the wire rope, and transmit it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com