Titanium extraction tailings washing device and process

A technology for extracting titanium tailings and washing devices, which is applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of polluting the surrounding environment and occupying large land, and achieves easy automatic control, convenient operation, and realization of granularity The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

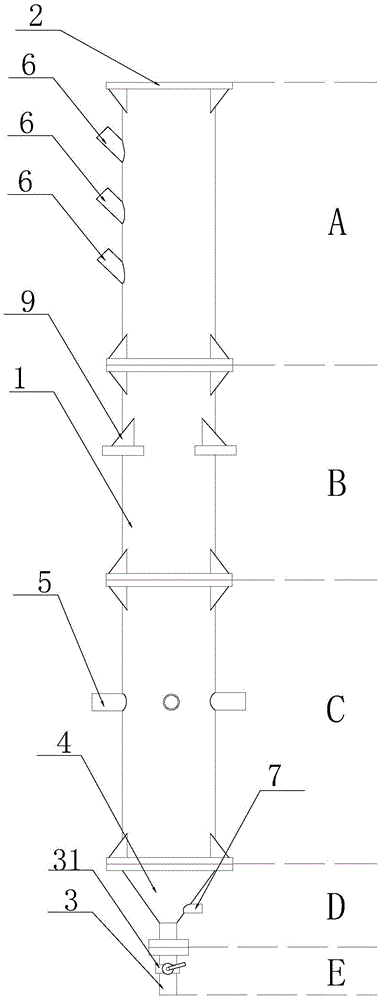

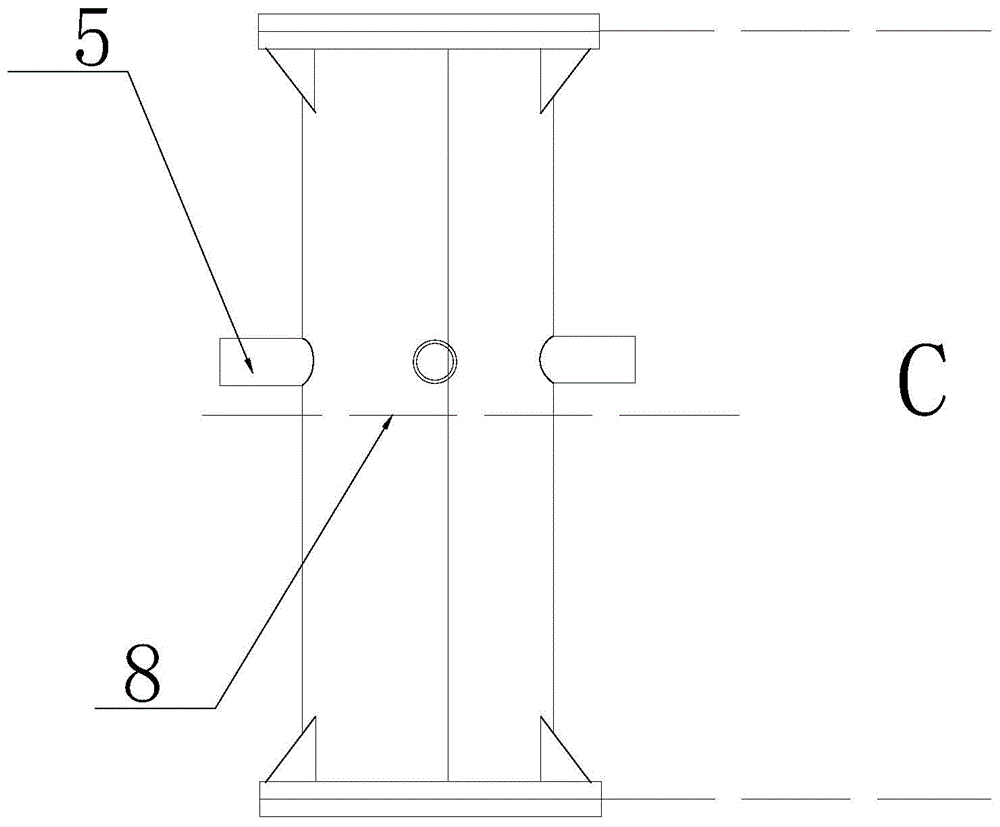

[0024] Such as figure 1 As shown, the titanium tailings washing device disclosed in the present invention includes a cylinder body 1, the top end of the cylinder body 1 is a feed inlet 2, the bottom end of the cylinder body 1 is a cone structure 4, and the cone structure 4 A slag discharge port 3 is provided at the lower end, and a slag discharge valve 31 is provided on the slag discharge port 3 , an overflow port 6 is provided at the upper part of the cylinder body 1 , and a water inlet 5 is provided at the middle part of the cylinder body 1 .

[0025] The working principle of the device is as follows:

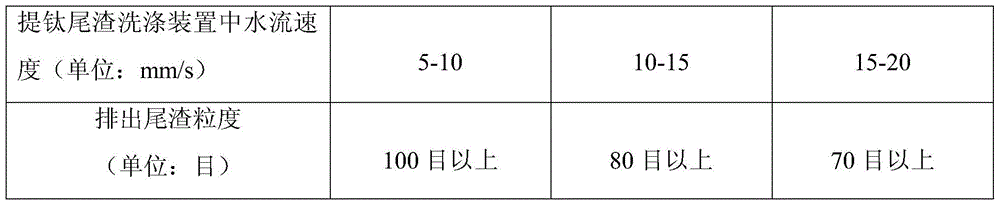

[0026] First, inject water from the water inlet 5 to the cylinder body 1. When clear water overflows from the overflow port 6, evenly inject the titanium extraction tailings beating slurry into the feed port 2 at a certain rate, and keep water injection at the same t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com