Roller-changing device

A technology of roll changing device and self-locking device, which is applied to heat treatment equipment, furnaces, heat treatment furnaces, etc., can solve the problem of low replacement efficiency, reduce the strength and reduce the risk of scratching the furnace wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

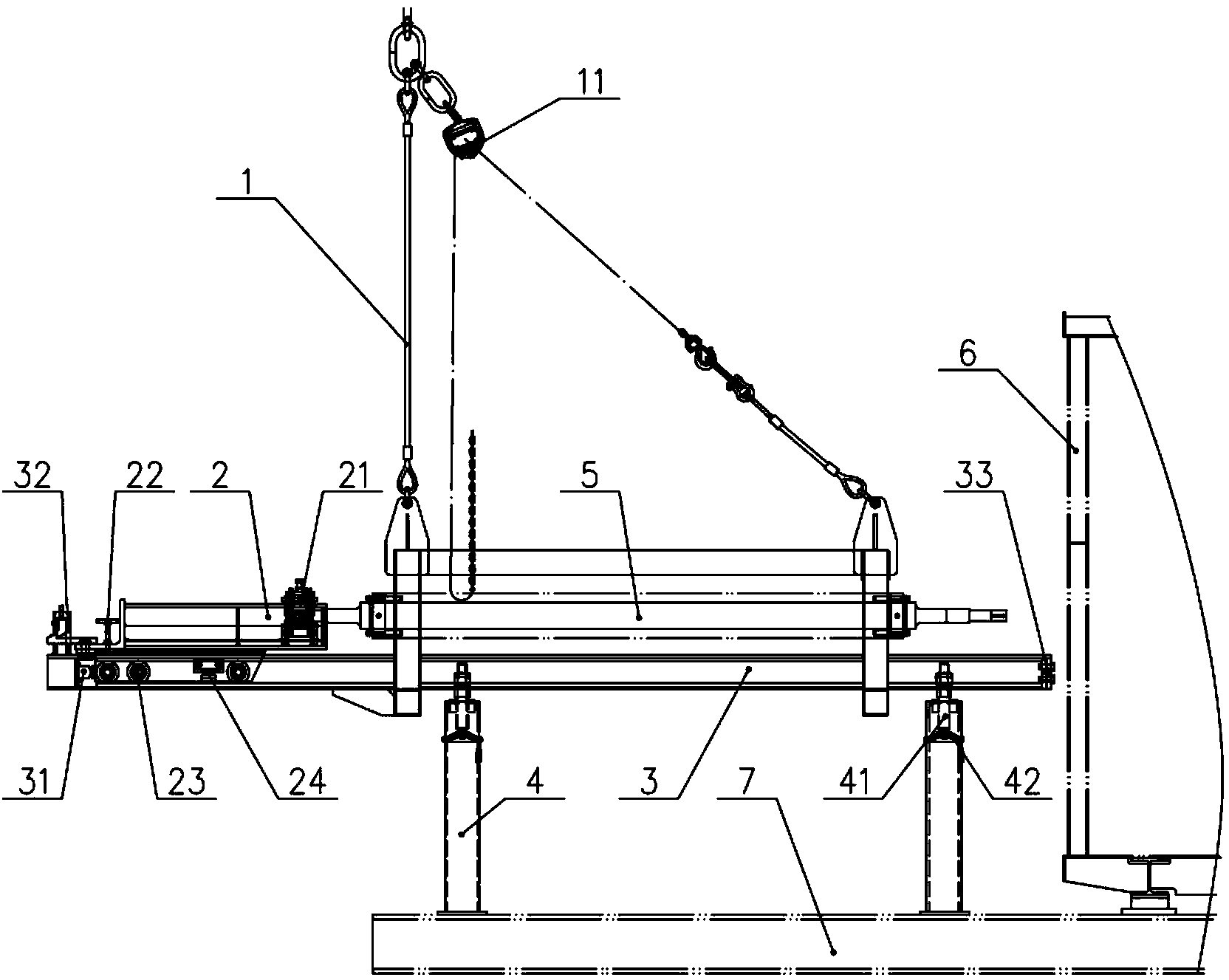

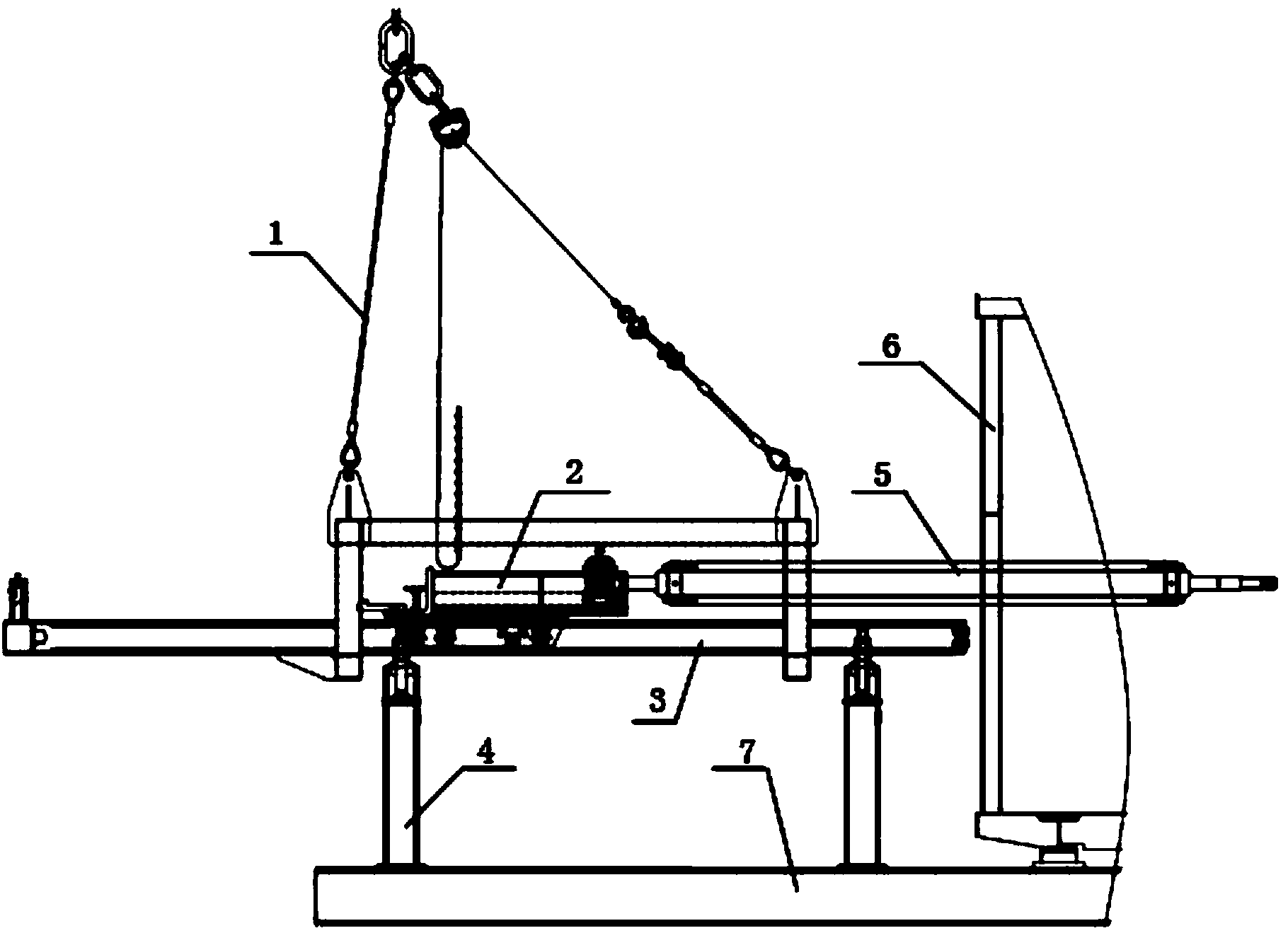

[0019] Such as figure 1 , figure 2 As shown, the roller changing device of the present invention includes a track 3 , a suspension rope 1 suspended above the track 3 , a trolley 2 moving on the track 3 , and a bracket 4 arranged at the bottom of the track 3 . The front part of the trolley 2 is provided with a pressing device 21 for connecting the furnace roller 5, the rear end of the trolley 2 is provided with a hook 25, and a self-locking device 32 cooperating with the hook 25 is arranged on the track 3.

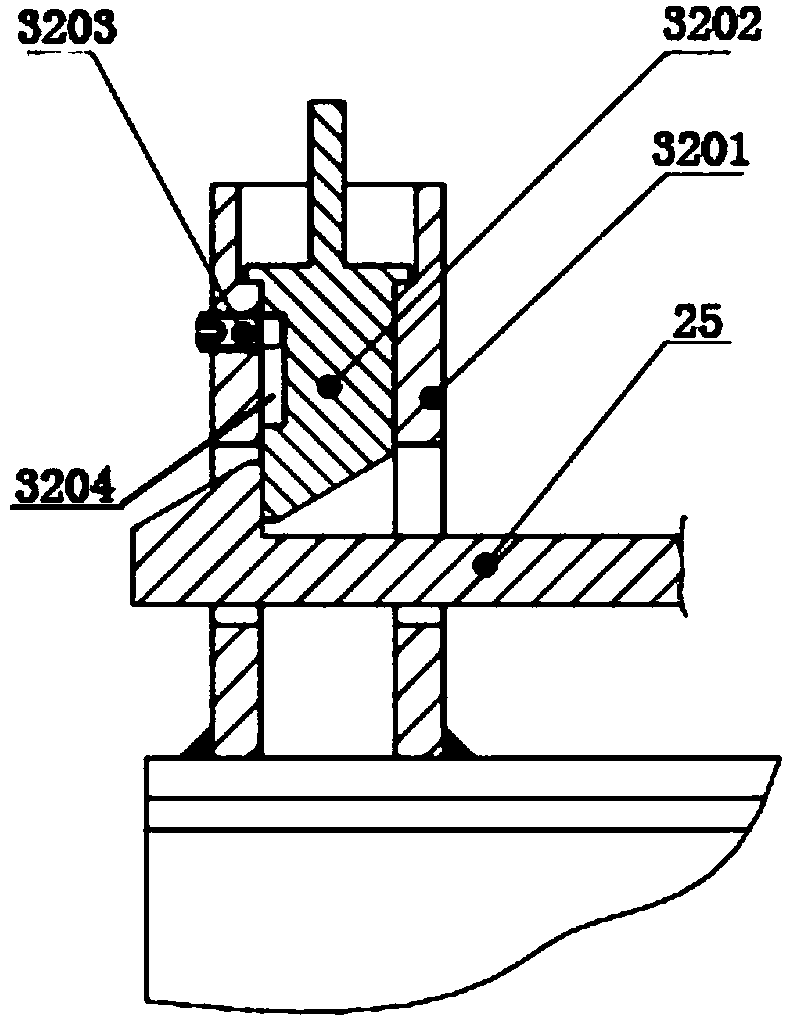

[0020] The self-locking device 32 comprises a weight 3202, a limit screw 3203 and a guide cylinder 3201, the weight 3202 is in the guide cylinder 3201, the weight 3202 is provided with a guide groove 3204, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com