Pneumatic vacuum generator

A vacuum generator and air pressure technology, which is applied in the direction of machines/engines, non-displacement pumps, mechanical equipment, etc., can solve the problems of difficult control of vacuum degree, high energy consumption, heavy weight, etc., and achieve small surface leakage and adsorption volume The effect of small, low-cost manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

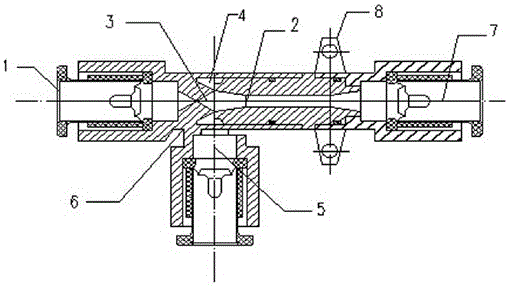

[0017] like figure 1 The innovation of the air pressure vacuum generator shown is that the air pressure vacuum generator includes an exhaust port 1, a Laval nozzle 2, a nozzle 3, a negative pressure chamber 4, a vacuum port 5, a housing 6 and an air inlet 7;

[0018] The exhaust port 1, the nozzle 3, the negative pressure chamber 4, the Laval nozzle 2, and the air inlet 7 are sequentially arranged in the air pressure vacuum generator housing 6, and the Laval nozzle 2 and the exhaust port 1 are connected through the nozzle 3 , a vacuum port 5 is installed in the vertical direction of the nozzle 3, the negative pressure chamber 4 is located at the interface between the Laval nozzle 2 and the nozzle 3, and the air inlet 7 is connected to one end of the Laval nozzle 2;

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com