Composite refining and modifying agent capable of improving friction and wear properties of multi-element aluminum-silicon alloy

A technology for refining modifiers and aluminum-silicon alloys, which is applied in the field of casting aluminum-silicon alloy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

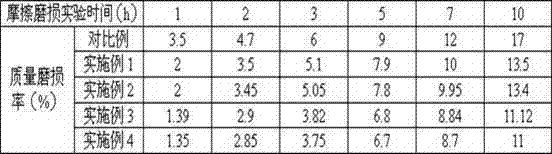

Examples

Embodiment 1

[0012] The material is cast aluminum-silicon alloy, and the raw materials are commercially available. The specific chemical composition (mass percentage) is: Si 7-8%, Cu 3-4%, Mg 0.3-0.4%, Mn 0.2-0.3%, Zn 0.4-0.5 %, Fe≤0.35%, the rest is Al. Electromagnetic induction graphite crucible aluminum melting furnace is used for melting. In addition to Mg, Zn and composite refinement modifier, other raw materials are added into the graphite crucible, melted at 775°C, cooled to 735°C and added with Mg and Zn, and then added with composite refinement modifier (chemical composition is calculated by mass percentage, Ti is 10%, Cr is 8%, Ni is 8%, Sr is 8%, Ce is 5%, La is 5%, Nb is 5%, Pr is 3%, Er is 3%, Eu is 3%, Y is 3%, Ba is 3%, B is 2%, Na is 2%, V is 1%, and the rest is Al), and the addition amount is 0.2%. Then, the commercially available HGJ-2 aluminum alloy sodium-free refining slag and degasser was used for degassing treatment. The addition amount was 0.5% of the total mass o...

Embodiment 2

[0014] The material is cast aluminum-silicon alloy, and the raw materials are commercially available. The specific chemical composition (mass percentage) is: Si 7-8%, Cu 3-4%, Mg 0.3-0.4%, Mn 0.2-0.3%, Zn 0.4-0.5 %, Fe≤0.35%, the rest is Al. Electromagnetic induction graphite crucible aluminum melting furnace is used for melting. In addition to Mg, Zn and composite refinement modifier, other raw materials are added into the graphite crucible, melted at 775°C, cooled to 735°C and added with Mg and Zn, and then added with composite refinement modifier (chemical composition is calculated by mass percentage, Ti is 14%, Cr is 10%, Ni is 10%, Sr is 10%, Ce is 7%, La is 7%, Nb is 7%, Pr is 4%, Er is 4%, Eu is 4%, Y is 4%, Ba is 4%, B is 3%, Na is 3%, V is 2%, and the rest is Al), and the addition amount is 0.8%. Then, the commercially available HGJ-2 aluminum alloy sodium-free refining slag and degasser was used for degassing treatment. The addition amount was 0.5% of the total mas...

Embodiment 3

[0016] The material is cast aluminum-silicon alloy, and the raw materials are commercially available. The specific chemical composition (mass percentage) is: Si 7-8%, Cu 3-4%, Mg 0.3-0.4%, Mn 0.2-0.3%, Zn 0.4-0.5 %, Fe≤0.35%, the rest is Al. Electromagnetic induction graphite crucible aluminum melting furnace is used for melting. In addition to Mg, Zn and composite refinement modifier, other raw materials are added into the graphite crucible, melted at 775°C, cooled to 735°C and added with Mg and Zn, and then added with composite refinement modifier (chemical composition is calculated by mass percentage, Ti is 11%, Cr is 8%, Ni is 9%, Sr is 8%, Ce is 6%, La is 6%, Nb is 5%, Pr is 3.5%, Er is 3.5%, Eu is 3.5%, Y is 3%, Ba is 3%, B is 2.5%, Na is 2%, V is 1.5%, and the rest is Al), and the addition amount is 0.4% of the total mass of the alloy liquid. Then use a commercially available degasser for degassing treatment, the addition amount is 0.5% of the total mass of the alloy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com