Shock absorber for suspension systems of large excavators

A suspension system and excavator technology, applied in the direction of earth mover/shovel, non-rotational vibration suppression, construction, etc., can solve problems affecting service life, corrosion, etc., and achieve the effect of prolonging service life and preventing local damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

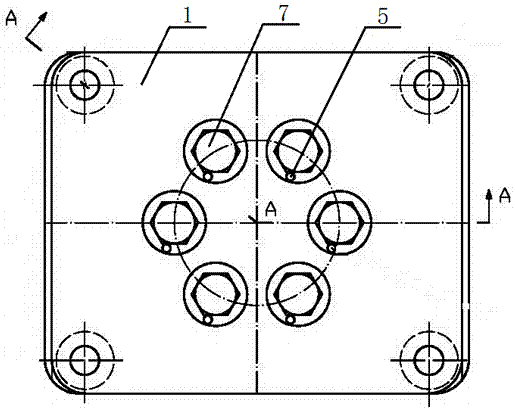

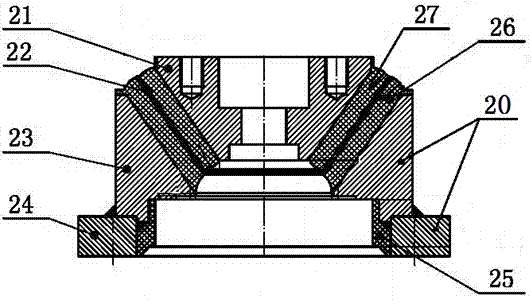

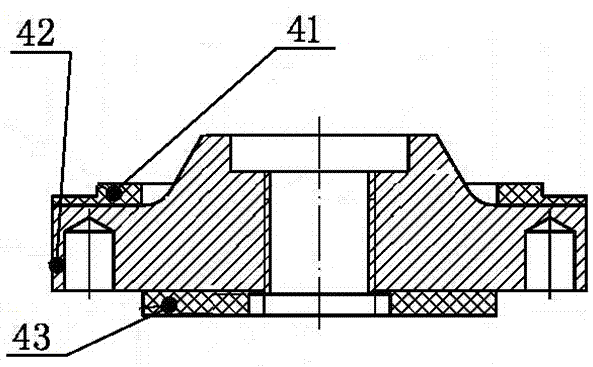

[0021] Such as figure 1 with figure 2 As shown, a shock absorber for a suspension system of a large excavator of the present invention is mainly composed of an upper cover plate 1, a support vulcanized body 2 and a protective plate vulcanized body 4; the protective plate vulcanized body 4 is provided with a support The base vulcanized body 2, the support vulcanized body 2 and the protective plate vulcanized body 4 are fixed together by connecting pieces; the upper cover plate 1 is installed above the support vulcanized body 2. The connecting piece is a hexagon socket head cap screw 6, and the hexagon socket cap screw 6 is locked by a conical pin 5.

[0022] In order to further prolong the service life of the present invention, a sleeve shaft 3 is provided between the protective plate vulcanization body 4 and the support vulcanization body 2 for position limiting. When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com