High-pressure air-cooling roots blower

A Roots blower, air cooling technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of damage to the connection between the impeller and the rotating shaft, performance degradation of the fan, damage to the fan, etc., to ensure rigidity, smooth operation, and longevity. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The features and principles of the present invention will be described in detail below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, not to limit the protection scope of the present invention.

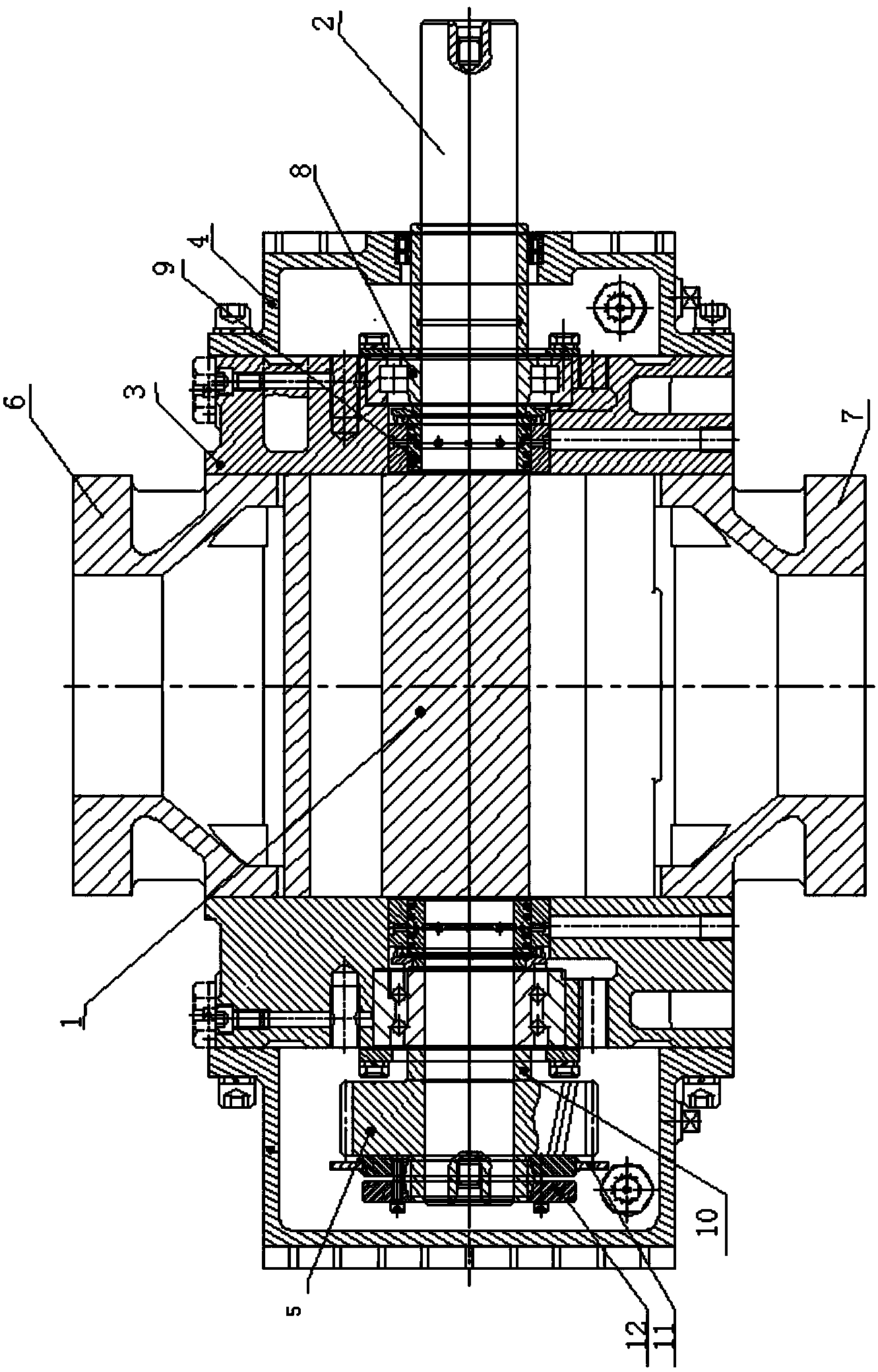

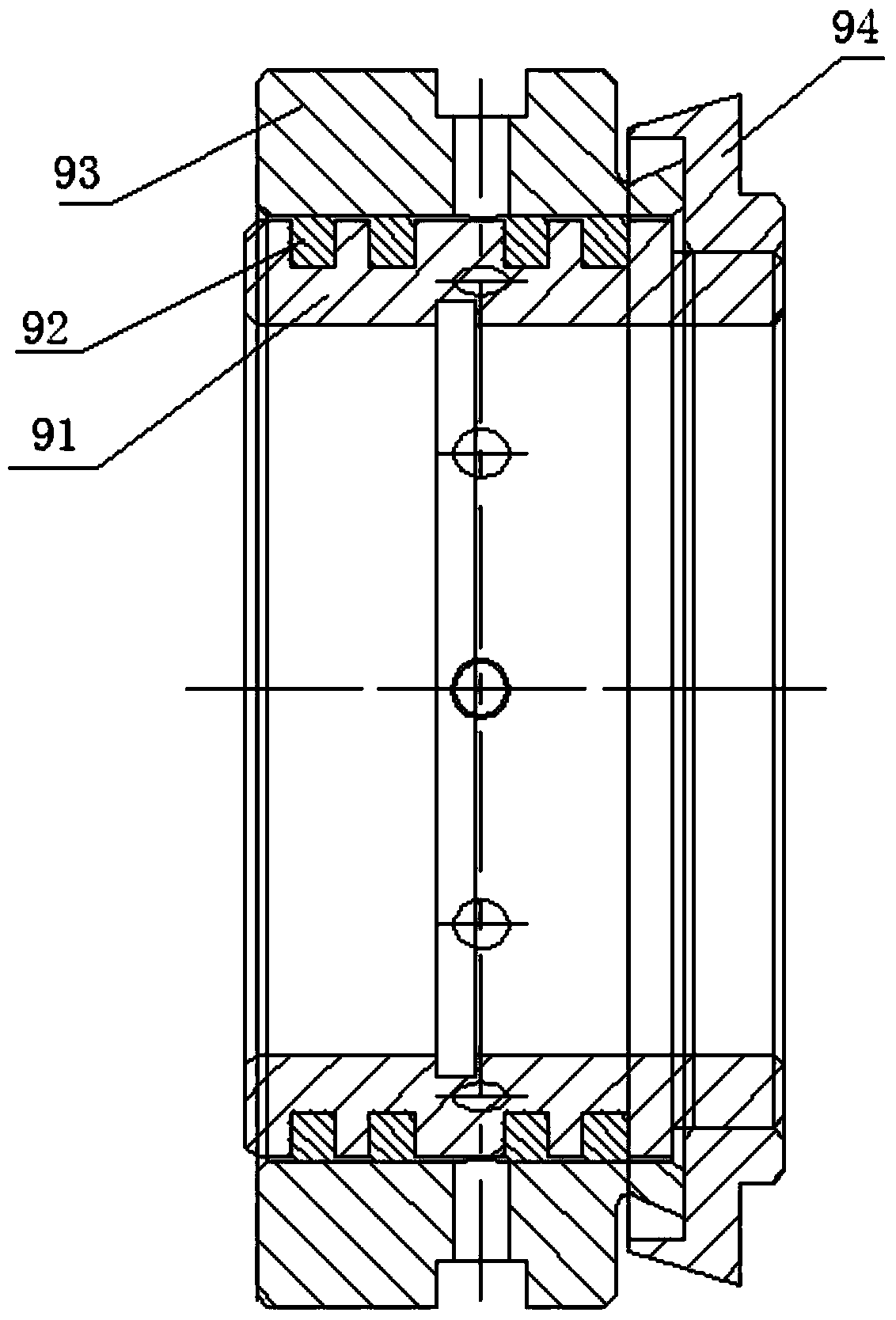

[0014] Such as figure 1 As shown, the high-pressure air-cooled Roots blower includes a casing, an impeller 1, a rotating shaft 2, a wall panel 3, an oil tank 4 and a gear 5.

[0015] The air inlet pipe and the air outlet pipe are respectively vertically welded on the outer peripheral surface of the casing, and the air outlet pipe and the air inlet pipe are coaxially distributed so as to make the wind flow more smoothly.

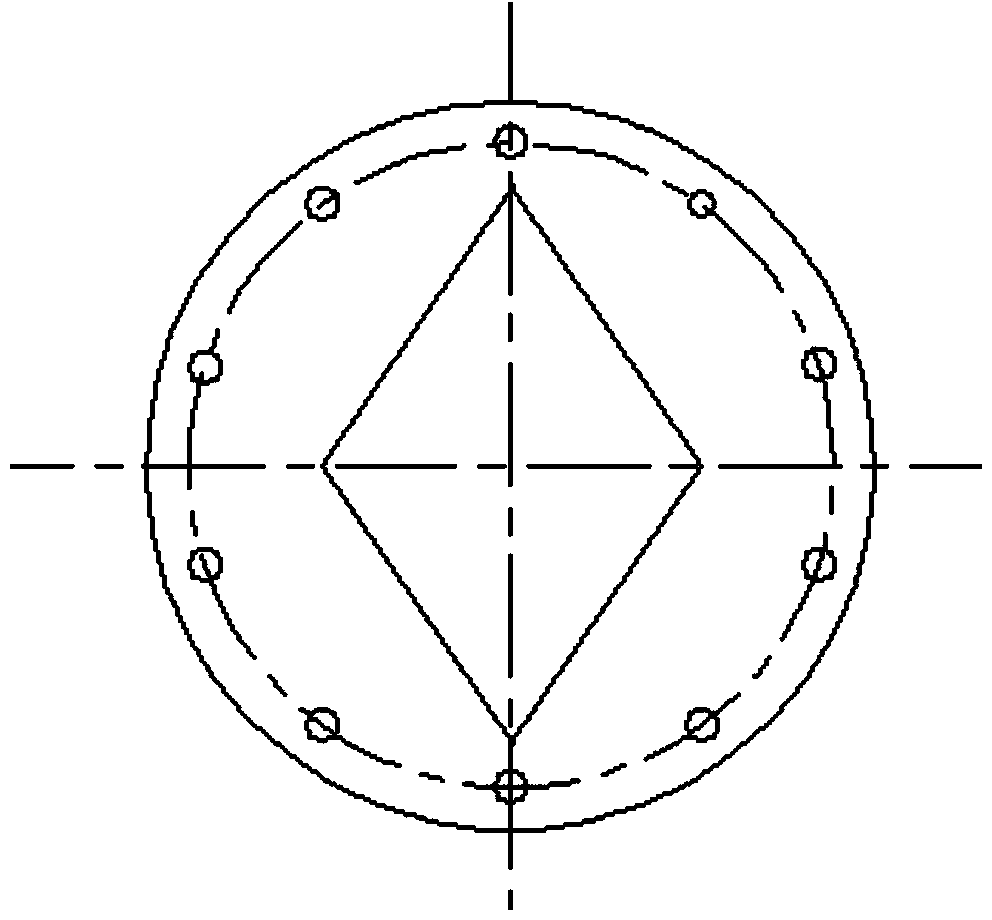

[0016] Such as figure 2 As shown, the cross-sections of the inlet 6 of the air inlet pipe and the outlet 7 of the air outlet pipe are designed to be diamond-shaped, which better ensures the concentration of the air volume.

[0017] And the opening direction of the outlet of the air outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com