On-line carbon fiber stability monitoring device and on-line carbon fiber stability monitoring method

A monitoring device and carbon fiber technology, applied in the field of carbon fiber, can solve problems such as poor timeliness and inability to achieve long-distance full inspection, and achieve the effect of ensuring effective judgment, ensuring non-destructive testing and stability, and fast feedback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

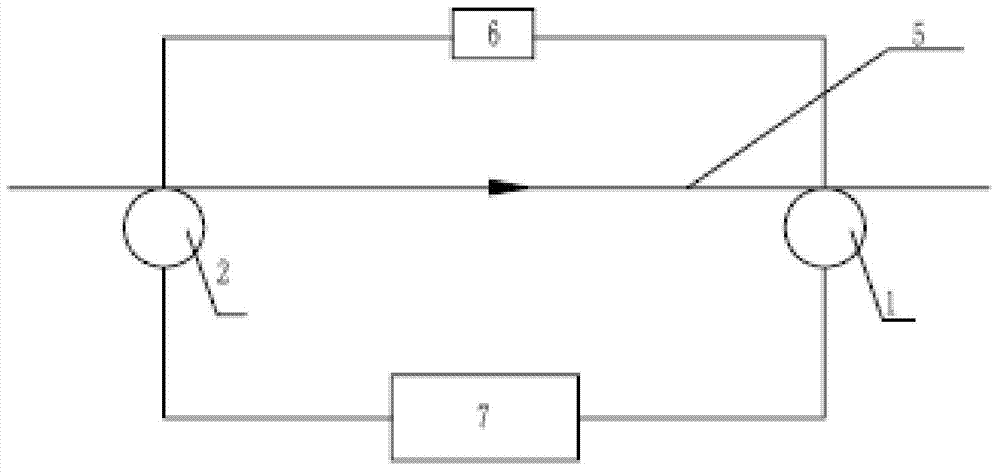

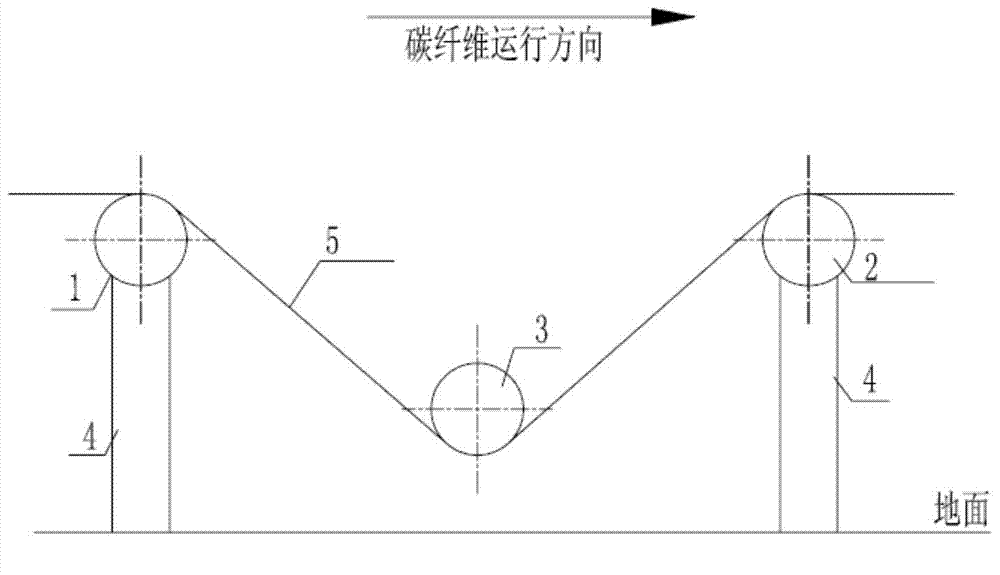

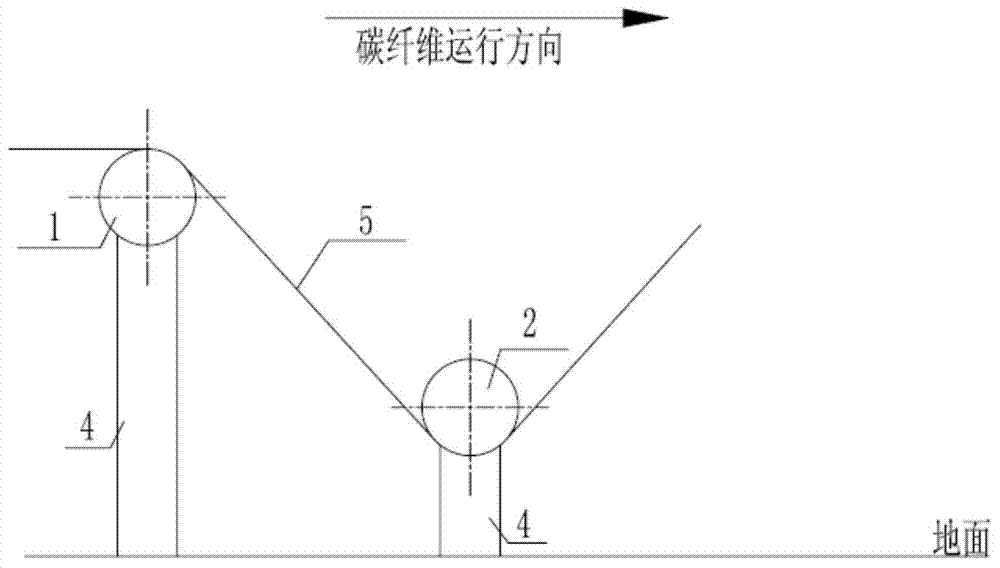

[0031] The device is located between carbonization and surface treatment.

[0032] Design parameters: Tow spacing: 10mm (center distance between adjacent tows), 4-5mm (net distance between adjacent tows)

[0033] Tow width: 5-6mm; effective test length: 200-400mm; DC voltage: 6-12V, (using constant voltage power supply) scope of application: T800-6K / 12K; current measurement accuracy: 1mA

Embodiment 2

[0035] Taking T800-6K carbon fiber as an example, the theoretical resistance calculation is performed as follows:

[0036] Calculation formula: Tow amount: 6K; single wire diameter: 5.10μm; resistivity ρ: 1.4×10 -3 Ω·cm; length l: 1.0m; A is the cross-section of the tow; it can be known by calculation that R=120Ω.

[0037] Therefore, the theoretical resistance of T800-6K carbon fiber tow is 120Ω / m; calculated according to this, the theoretical resistance of T800-12K carbon fiber tow is 60Ω / m.

[0038] According to the above calculation results, by installing an online resistance measurement and control system at the end of the carbonization process of the carbon fiber production line, the resistance test of carbon fiber products can be realized, and real-time detection can be achieved, and evaluation can be made according to the change of resistance of each bundle of fibers Long-distance, inter-axis and batch-to-batch stability of the product, rapid recording and feedback o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com