Pulse eddy current detection lift-off effect inhibiting method based on high-pass filtering

A high-pass filtering, lift-off effect technology, applied in the direction of material magnetic variables, etc., can solve the problem of the influence of voltage noise of differential signals, and achieve the effect of accurate indication, accurate indication, and accurate lift-off height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

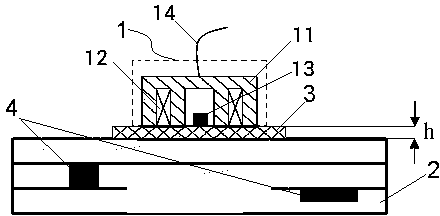

Image

Examples

Embodiment

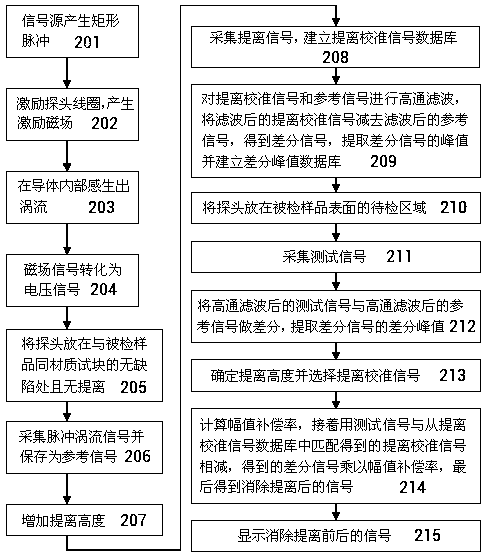

[0050] Example : realize the embodiment flow process of the present invention as follows:

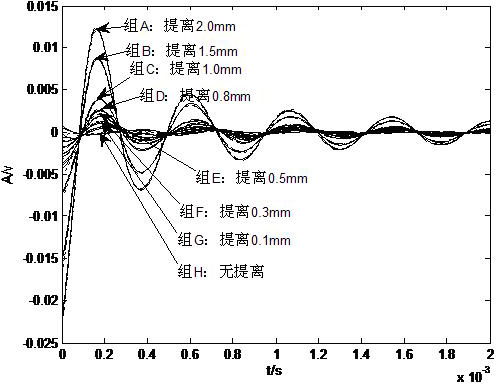

[0051] 1) First, place the probe 1 on a test block of the same material as the tested sample 2, which can be judged to be free of defects, and the probe 1 has not been lifted off. The signal at this time is collected as a reference signal. The lift-off height gradually increases, and the N lift-off calibration signals, establish a lift-off calibration signal database and record it as {L(n);n=0,1,…,N-1}.

[0052] For example, the lift-off height (mm) is 0, 0.1, 0.3, 0.5, 0.8, 1.0, 1.5, 2.0 in sequence, and 8 lift-off calibration signals are generated, n=0, 1, 2, 3, 4, 5, 6, 7.

[0053] 2) Secondly, perform high-pass filtering on the lift-off calibration signal and reference signal, subtract the filtered reference signal from the filtered lift-off calibration signal to obtain a differential signal, extract its differential peak value, establish a differential peak value database and re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com