Optimization design method of Austempered ductile iron alloy composition based on Jmatpro material performance computation

A technology for optimizing design and material properties, applied in the field of new austempered ductile iron, it can solve the problems of low efficiency, high cost and long time, and achieve the effect of reducing cost, improving efficiency and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A method for optimizing the design of the Aube ductile iron alloy composition based on Jmatpro material performance calculation, characterized in that the method for optimizing the design comprises the following steps:

[0026] (1) For the optimal design of the basic components C, Si, Mn, P, and S, first select the variation range of each element and determine each component;

[0027] (2) Open the Jmatpro software, call the Cast Iron module and the corresponding database;

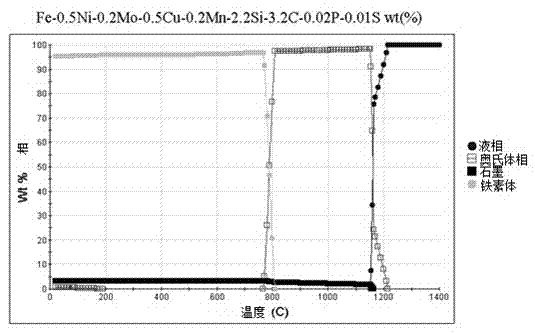

[0028] (3) Select the basic composition of a component and input it into the software, select the material property option Step Temperature to be calculated, set the calculation temperature range from 1400°C to 20°C, and calculate the step size of 10°C, and calculate the temperature-phase composition diagram, see figure 1 ;

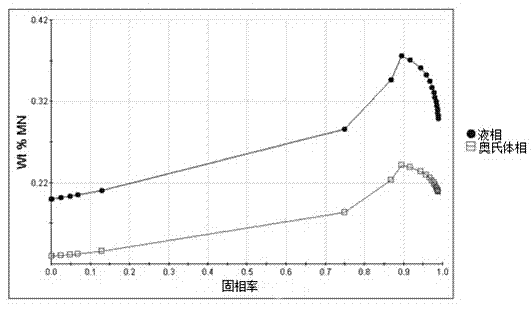

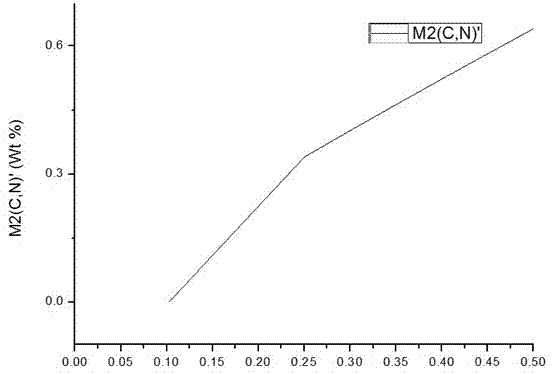

[0029] (4) Select Phases and Properties to calculate the material performance option to calculate the phase composition and thermal properties during the solidification process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com