Traction mechanism suitable for hull type floating nuclear power plant

A traction mechanism and nuclear power plant technology, applied in the field of floating nuclear power plants, can solve problems such as unfavorable reactors and large shaking of floating nuclear power plants, and achieve the effects of reducing impact force, reducing up and down fluctuations, and avoiding shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

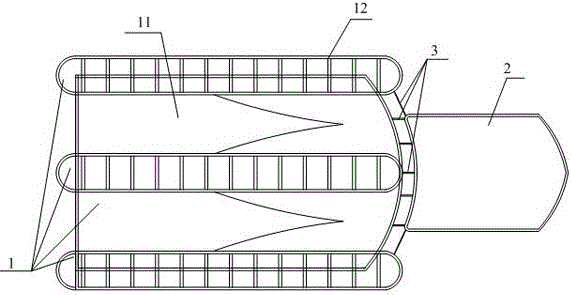

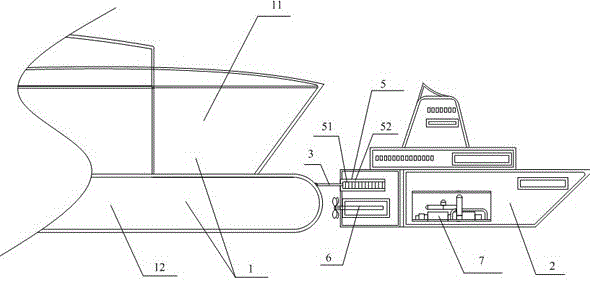

[0029] Such as figure 1 with figure 2 As shown, the towing mechanism suitable for hull-type floating nuclear power plants includes a towing ship 2 and a connecting device, and the connecting device includes a plurality of connecting hinge rods 3 connected between the head of the floating nuclear power plant 1 and the tail of the towing ship 2, and the connecting hinges The rod 3 is connected to the head of the floating nuclear power plant 1 through the fixed joint 4, and the tail of the tow ship 2 is connected to the hinge rod connection device 5, and a plurality of connecting hinge rods 3 are connected to the head of the floating nuclear power plant 1 and the tail of the tow ship 2 in a dispersed manner. The connection means that there are multiple connecting points between the hinge rods 3 and the head of the floating nuclear power plant 1 and the tow ship 2, specifically: there are multiple hinge rod connection devices 5 at the tail of the tow ship 2, which are distributed...

Embodiment 2

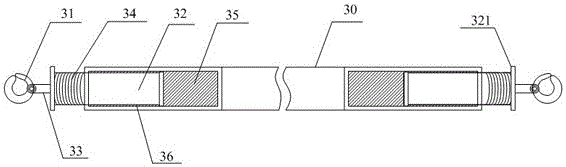

[0031] On the basis of Embodiment 1, the structure of the connecting hinge bar 3 is further limited in this embodiment:

[0032] Such as image 3 with Figure 5 As shown, the connecting hinge rod 3 includes a rod body 30, an anchor hook 31, a pressing block 32, a connecting rod 33, a damping spring 34, a rubber damping block 35, and a rubber damping layer 36. The rod body 30 of the connecting hinge rod 3 has two The end is provided with a shock absorbing cavity 37, and the rubber damping block 35 is arranged in the shock absorbing cavity 37, and the pressure block 32 partly extends into the shock absorbing cavity 37 to contact with the rubber damping block 35, and is partially located in the shock absorbing cavity. Outside the cavity 37, and the pressure block 32 and the rubber damping block 35 are arranged side by side along the length direction of the connecting rod body 30, the pressing block 32 is closer to the end of the rod body 30, and the rubber damping block 35 is cl...

Embodiment 3

[0037] On the basis of any of the above-mentioned embodiments, the structure of the hinge rod connecting device 5 is further limited in this embodiment:

[0038] Described hinge link connecting device 5 comprises the cavity 51 that is arranged on the stern of towing ship 2 for accommodating the end of connecting hinge 3 and is arranged on the retraction mechanism 52 in cavity 51; The rear end of the cavity 51 extends into the cavity 51; the front end of the retraction mechanism 52 is fixedly connected to the front cavity wall of the cavity 51, and the rear end is fixedly connected to the connecting hinge rod 3, which can be connected to it when cornering and under the impact of waves. The end of the connecting hinge rod 3 shrinks into the cavity to limit the up and down swing of the connecting hinge rod 3, thereby generating a pulling force on the floating nuclear power plant 1 and reducing the up and down fluctuation of the floating nuclear power plant 1. In this embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com