Shape memory alloy actuation apparatus

An actuating device and actuator technology, applied in projection devices, printing devices, machines/engines, etc., can solve problems such as reducing image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

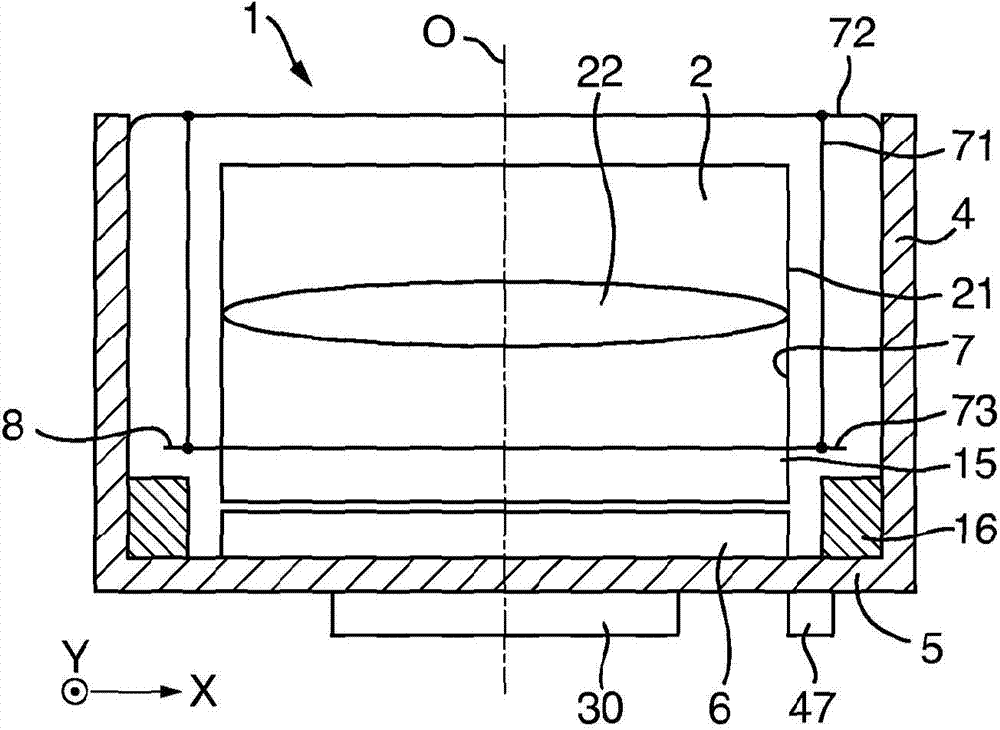

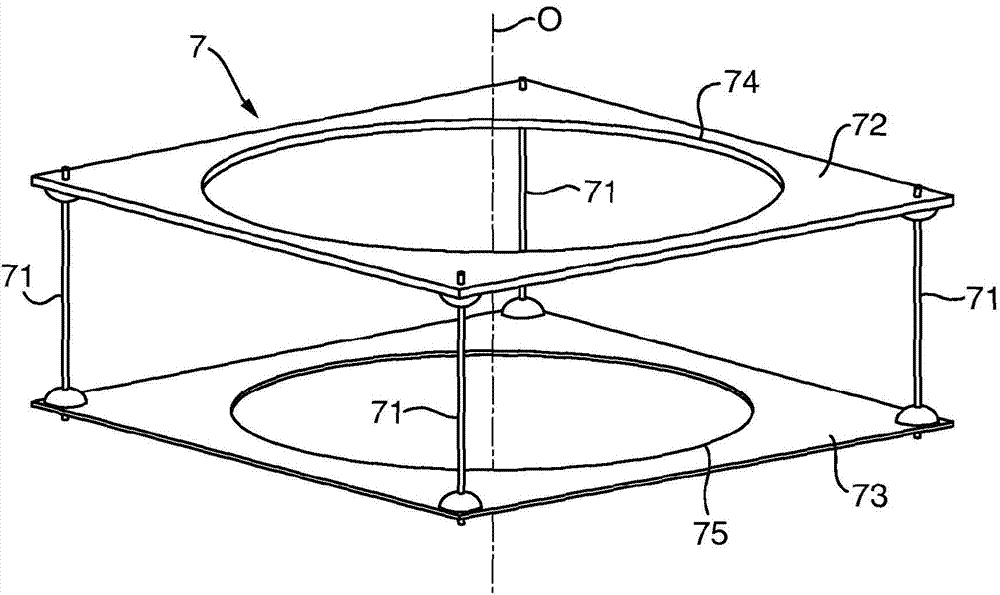

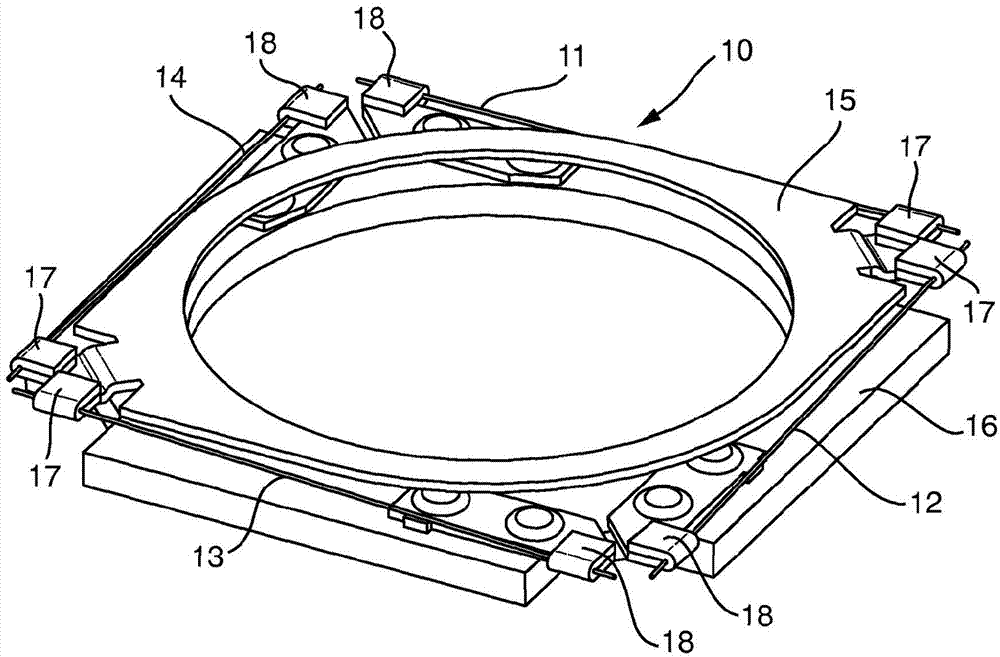

[0026] figure 1 A camera device 1 is shown as an example of an SMA actuating device according to the invention, figure 1 is a cross-sectional view taken along the optical axis O, which is the nominal principal axis. In order to clearly describe the main parts of the camera device 1, the SMA actuator wires are not in figure 1 shown in , but then refer to Figure 3-5 described. The camera arrangement 1 is to be incorporated into a portable electronic device like a mobile phone, media player or portable digital assistant. Miniaturization is therefore an important design criterion.

[0027] The camera device 1 comprises lens elements 2 supported on a support structure 4 by means of a suspension system 7 in such a manner that, as described in detail below, the lens elements 2 are Two orthogonal directions of O move relative to the support structure 4 . Thus, the lens element 2 is a movable element.

[0028] The support structure 4 is a camera mount supporting the image senso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com