Disk having an electrical connection element

A technology for connecting components and glass sheets, which is applied in the direction of electrical components, contact parts, parts of connecting devices, etc., can solve the problems of high price of connecting components, poor adhesion, poor weldability of titanium, etc., and achieve the effect of reducing mechanical stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

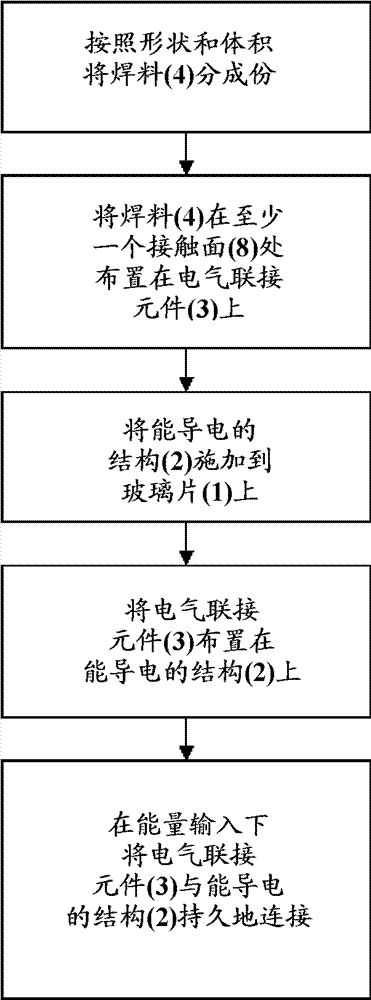

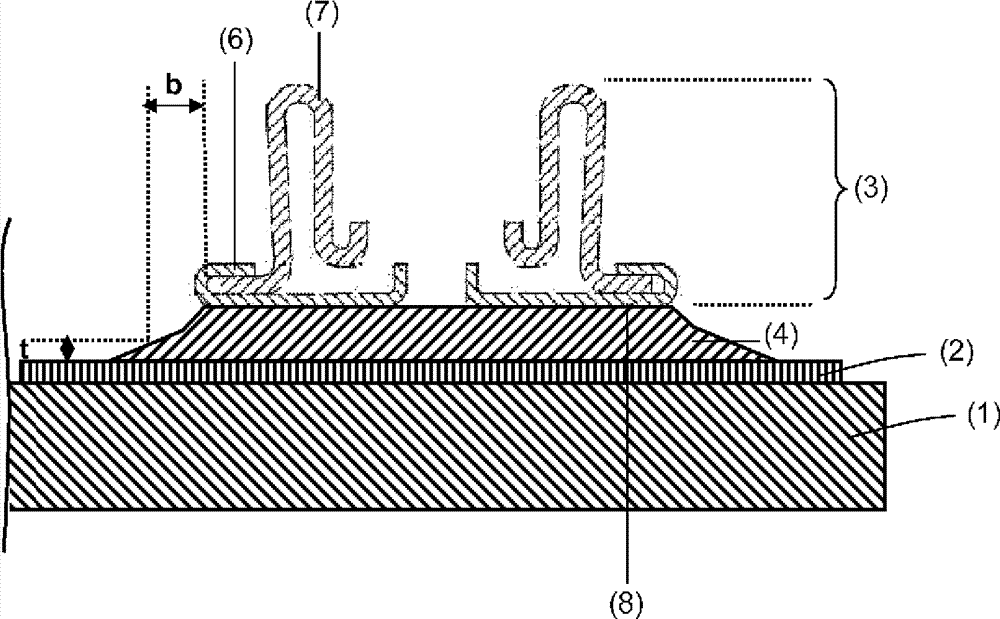

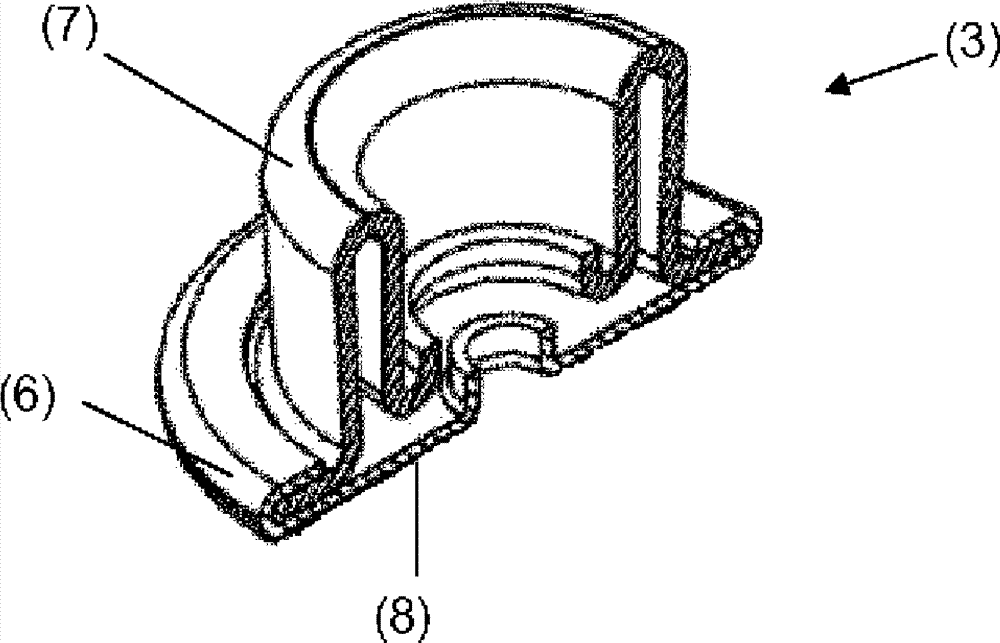

[0061] figure 1 A cross section through the heatable glass pane 1 according to the invention in the region of the electrical connection element 3 is shown. The glass pane 1 is a 3 mm thick thermally prestressed single pane of safety glass made of soda lime glass. The glass sheet 1 has a width of 150 cm and a height of 80 cm. An electrically conductive structure 2 in the form of a heating conductor structure 2 is embossed on the glass pane 1 . The electrically conductive structure 2 contains silver particles and glass frit. In the edge region of the glass pane 1 , the electrically conductive structure 2 is widened to a width of 10 mm and forms a contact area for the electrical connection element 3 . In addition, in the edge region of the glass pane 1 there is an overlay screen print (not shown). A solder 4 is applied in the region of the contact surface 8 between the electrical connection element 3 and the electrically conductive structure 2 , which brings about a permanent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com