Four-wheel driving sitting tillage machine

A four-wheel drive and tillage machine technology, applied in the field of agricultural tillage machines, can solve problems such as too large turning radius, achieve the effect of increasing the contact area and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

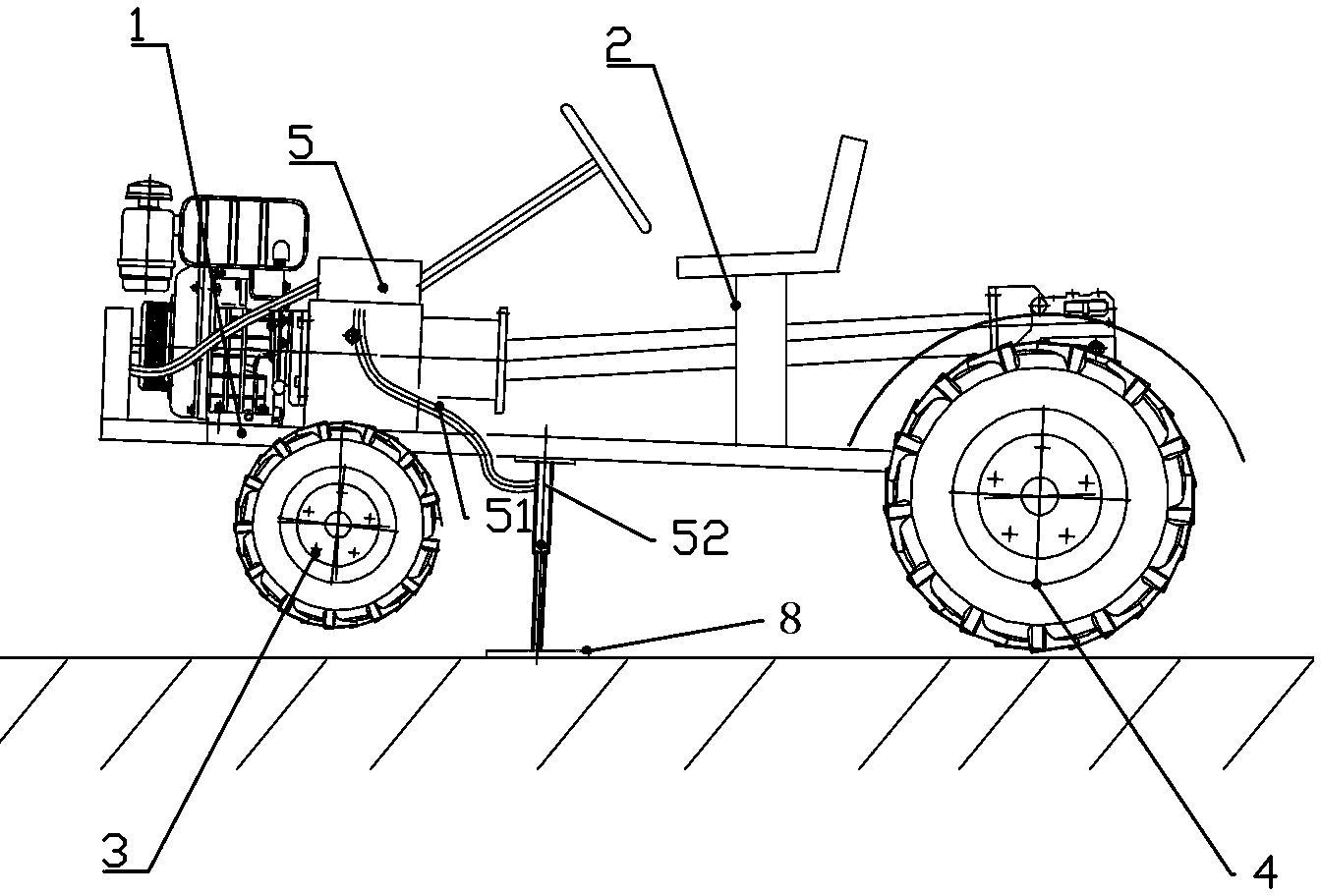

[0021] Embodiment 1: in combination with figure 1 The four-wheel-drive sitting cultivator shown includes a frame 1 on which a power device, a transmission device, a running device, a tillage device, a hydraulic device 5 and a driving platform 2 are arranged, and the driving platform 2 is located in the middle of the vehicle frame 1 , wherein the running gear includes a pair of front wheels 3 and a pair of rear wheels 4, clutch devices are installed on the pair of front wheels 3 and a pair of rear wheels 4, and a hydraulic support column 52 is hinged on the transverse central axis of the bottom of the vehicle frame 1, The installation position of the hydraulic support column 52 on the vehicle frame 1 is on the side close to the rear wheel 4. The advantage of such arrangement is that when the hydraulic support column 52 is jacked up to sit on the tiller, one side of the front wheel 3 is placed on the ground, which is convenient for sitting on the back. The cultivator turns, the ...

Embodiment 2

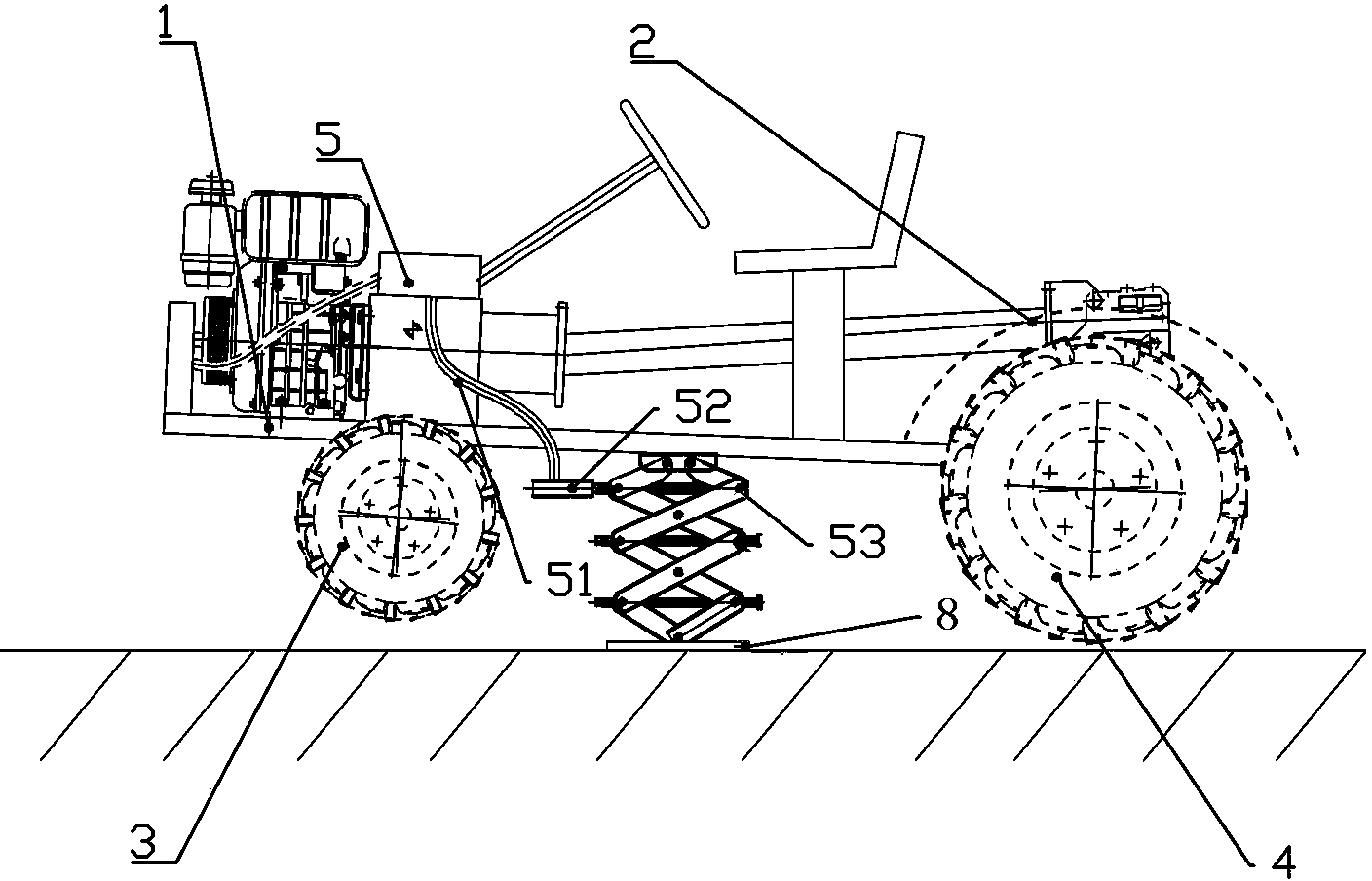

[0023] Embodiment 2: in combination with figure 1 The shown four-wheel drive sitting cultivator includes a vehicle frame 1, which is provided with a power unit, a transmission device, a running device, and a tillage device driver's platform 2, and the driver's platform 2 is located in the middle of the vehicle frame 1. Comprising a pair of front wheels 3 and a pair of rear wheels 4, the front wheels 3 and the rear wheels 4 are equipped with clutch devices, the bottom of the vehicle frame 1 is equipped with a scissor-type support arm, and the scissor-type support arm is pushed by a hydraulic arm 53. A hydraulic device 5 providing power for the hydraulic arm 53 is installed on the frame 1 , and a hydraulic control device for controlling the hydraulic device 5 is provided on the bridge 2 . The scissor support arm 54 is installed on the bottom of the vehicle frame 1 near the rear wheel 4 side. The bridge 2 is provided with a hydraulic control device for controlling the hydraulic ...

Embodiment 3

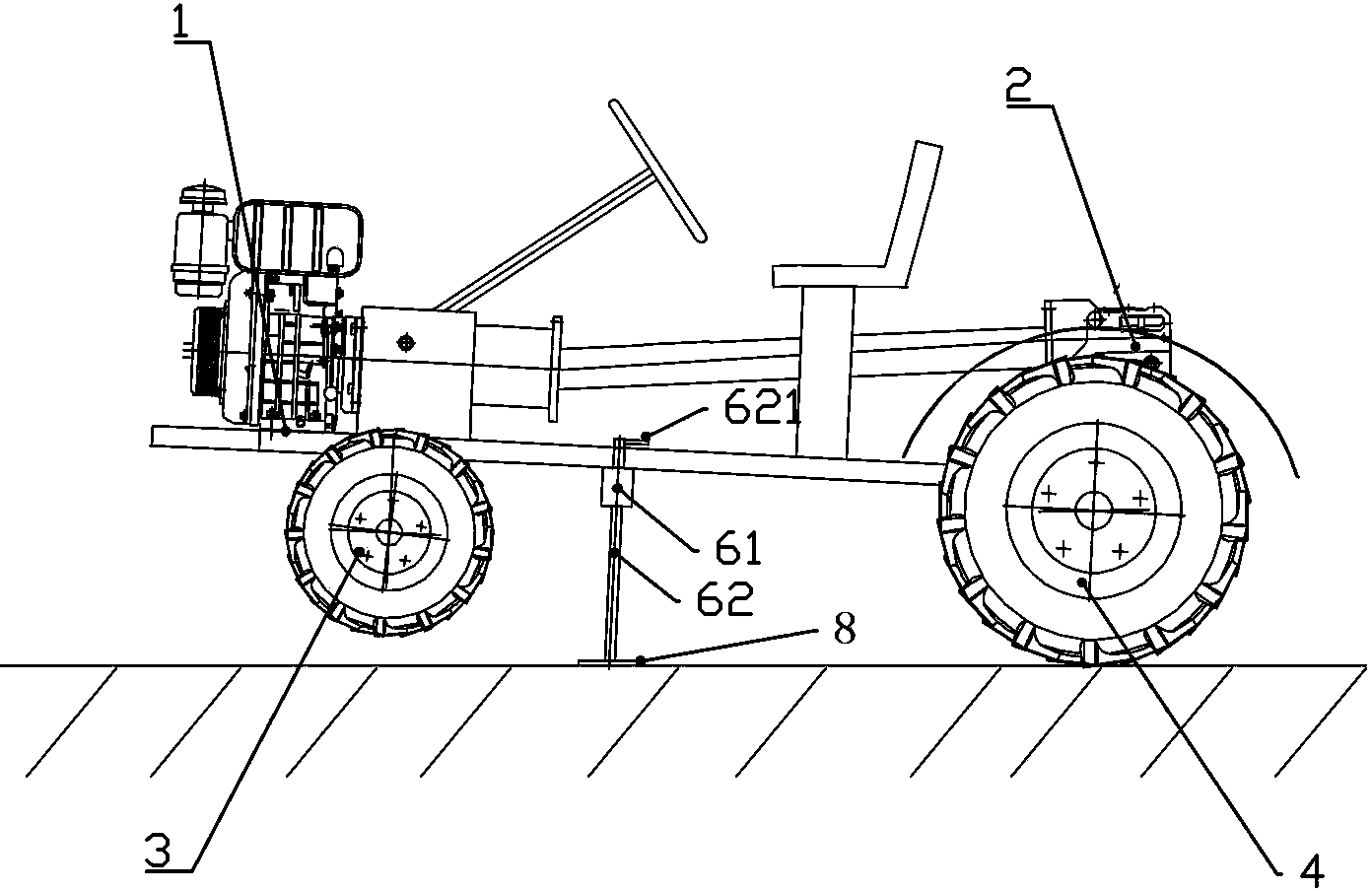

[0024] Embodiment 3: in combination with figure 1 The shown four-wheel drive sitting cultivator includes a vehicle frame 1, which is provided with a power unit, a transmission device, a running device, and a tillage device driver's platform 2, and the driver's platform 2 is located in the middle of the vehicle frame 1. It includes a pair of front wheels 3 and a pair of rear wheels 4, the front wheels 3 and the rear wheels 4 are equipped with clutch devices, and the bottom of the vehicle frame 1 is welded with screw rod support arms. The screw support arm includes a threaded cylinder 61 welded on the bottom of the vehicle frame 1, and also includes a screw 62 threadedly connected with the threaded cylinder 61. A section of the upper end of the screw 62 is bent to serve as a rotating handle 621. The bottom of the screw 62 is provided with a support plate 8. The screw support arm 54 is installed on the bottom of the vehicle frame 1 , on the geometric central axis of the vehicle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com