Hard surface vacuum cleaner and cleaning method thereof

A hard surface and cleaning machine technology, applied to machine parts, manual floor scrubbing machinery, etc., can solve problems such as difficult cleaning, secondary pollution of clothing and the environment, and harm to consumers' home health, so as to avoid pipeline blockage and cleaning Not easy to clean and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with drawings and embodiments.

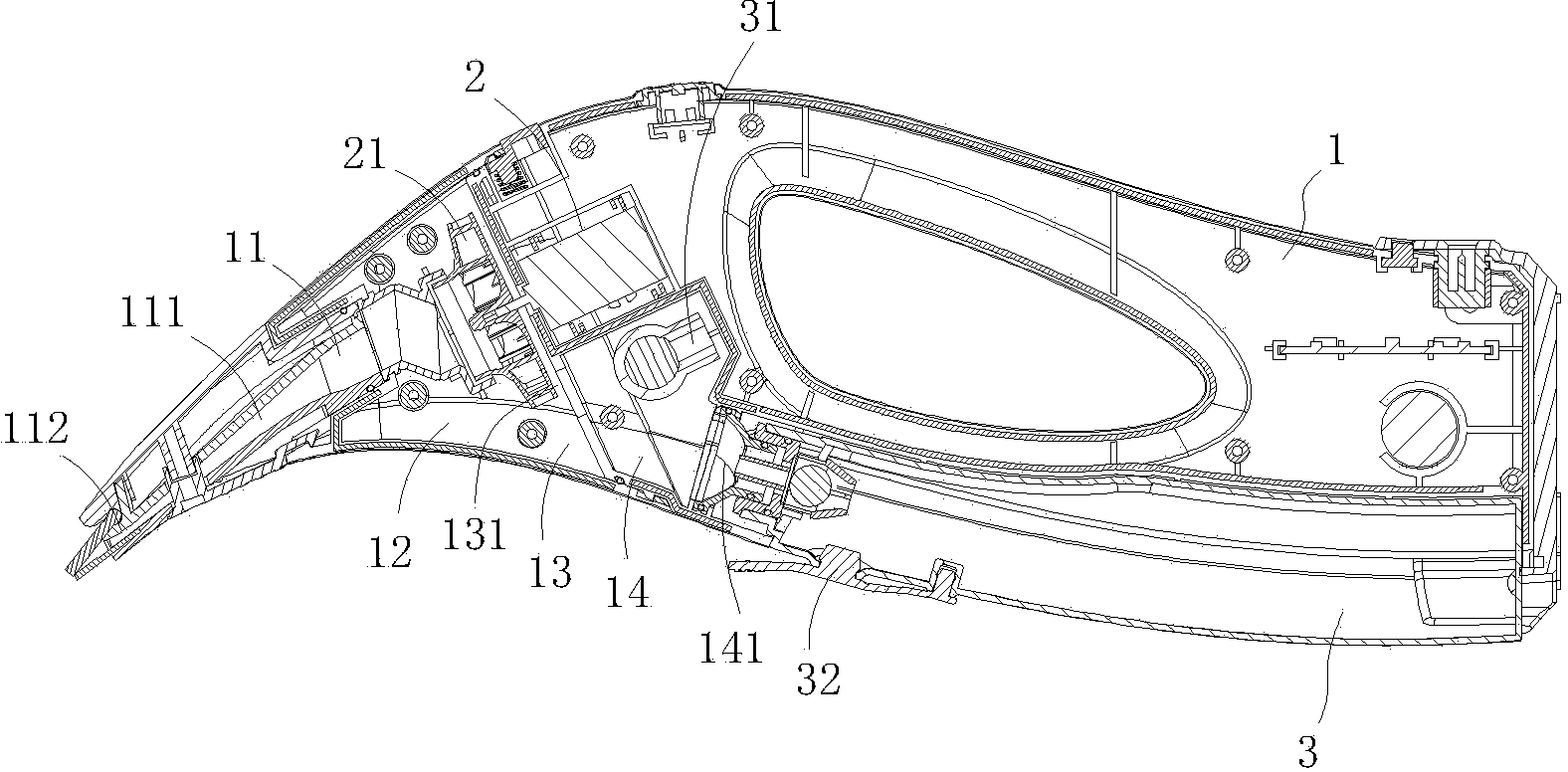

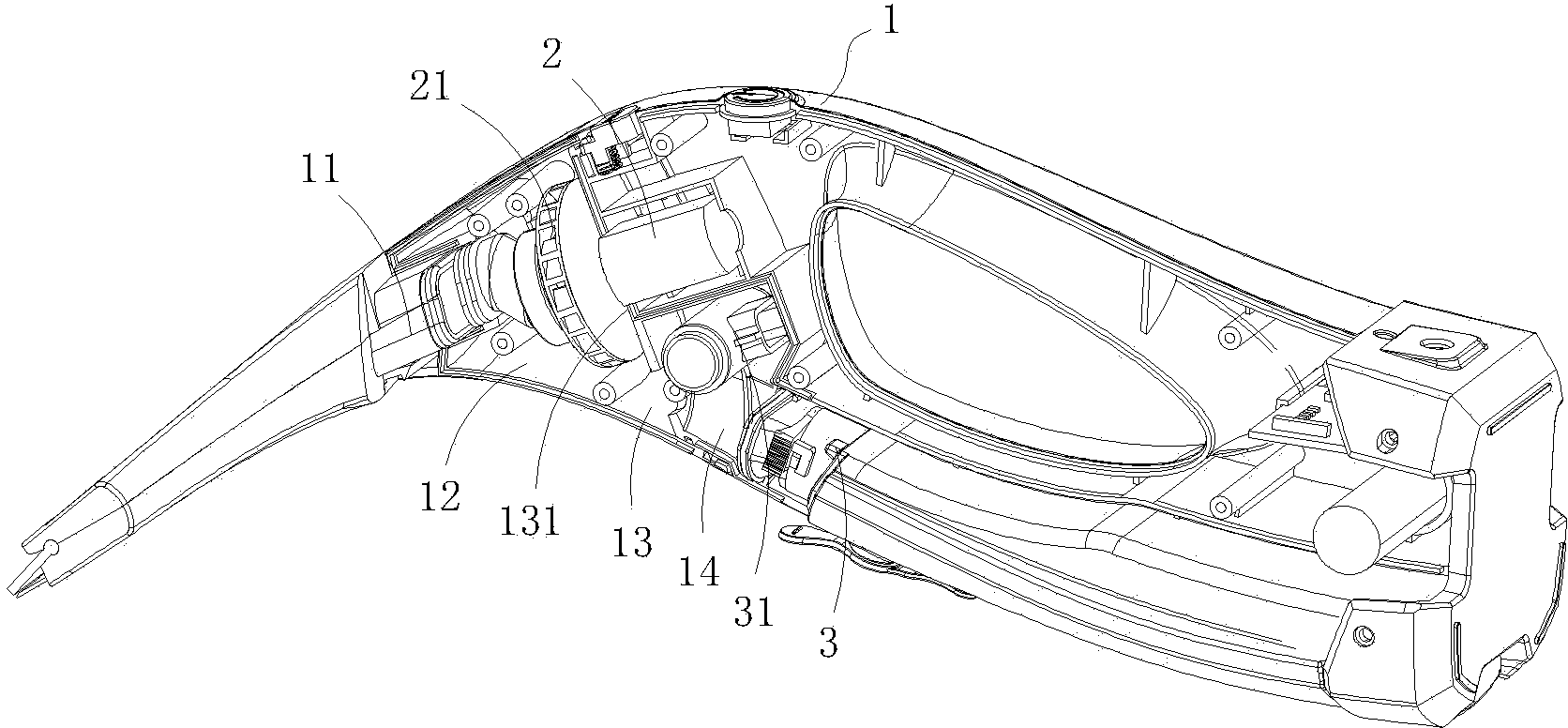

[0032] refer to Figure 1 to Figure 3 , a hard surface vacuum cleaner comprising:

[0033] The shell 1 has an accommodating space inside;

[0034] The negative pressure source 2 is set in the accommodating space, and the negative pressure source is combined with the centrifugal fan impeller 21 to generate centrifugal suction;

[0035] The main water tank 3 is located in the accommodating space;

[0036] The water vapor mixing suction channel 11, the air intake pipeline is arranged in the accommodating space, is a suction nozzle 111, and a suction pipe 112, and the suction pipe 112 is connected with the centrifugal fan impeller 21;

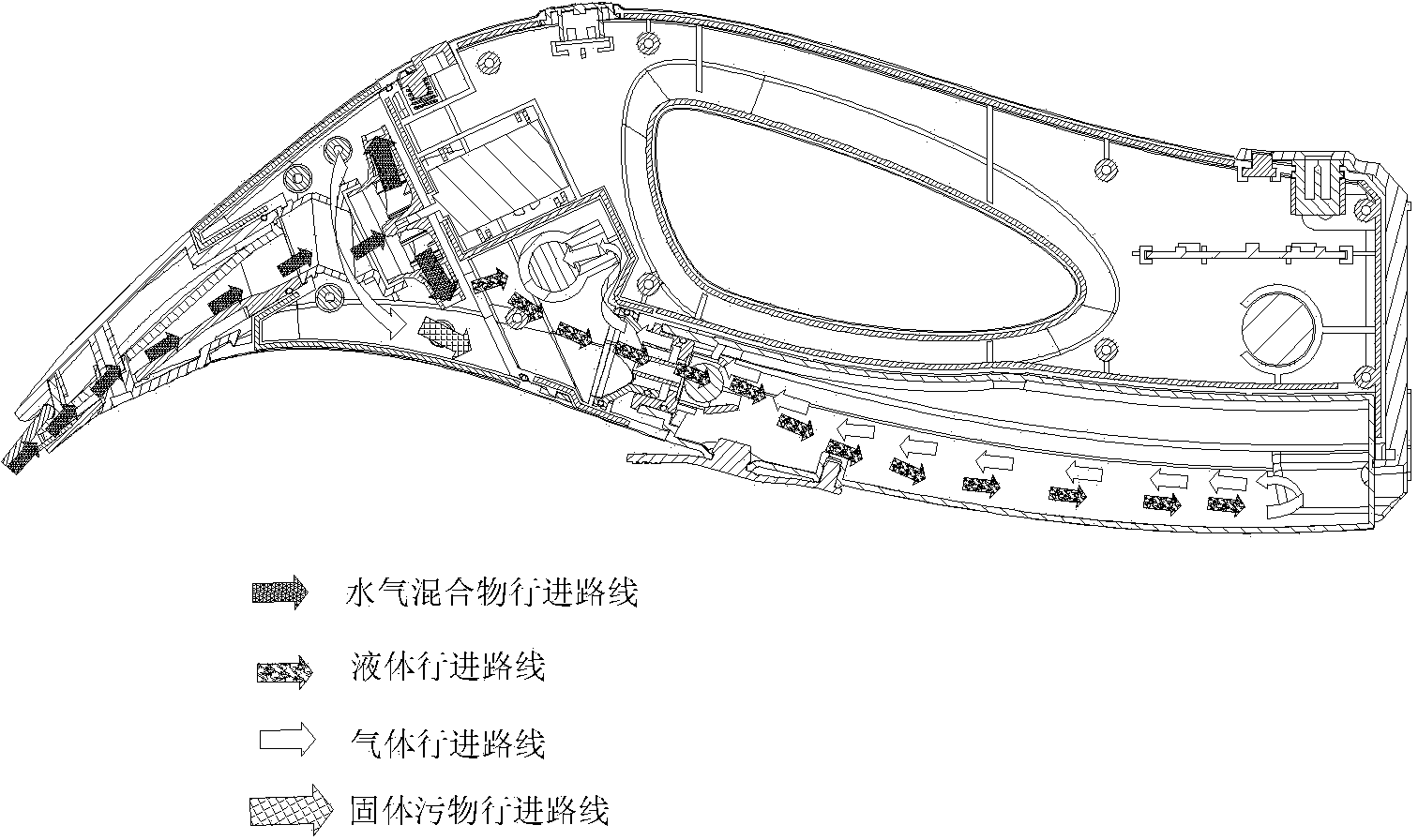

[0037] The water-air mixture vortex deceleration chamber 12, the solid waste temporary storage room 13, the liquid waste temporary storage room 14, and the main water tank 3 are arranged in the accommodating space, the water-air mixture v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com