Wire twisting structure tracheal stent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

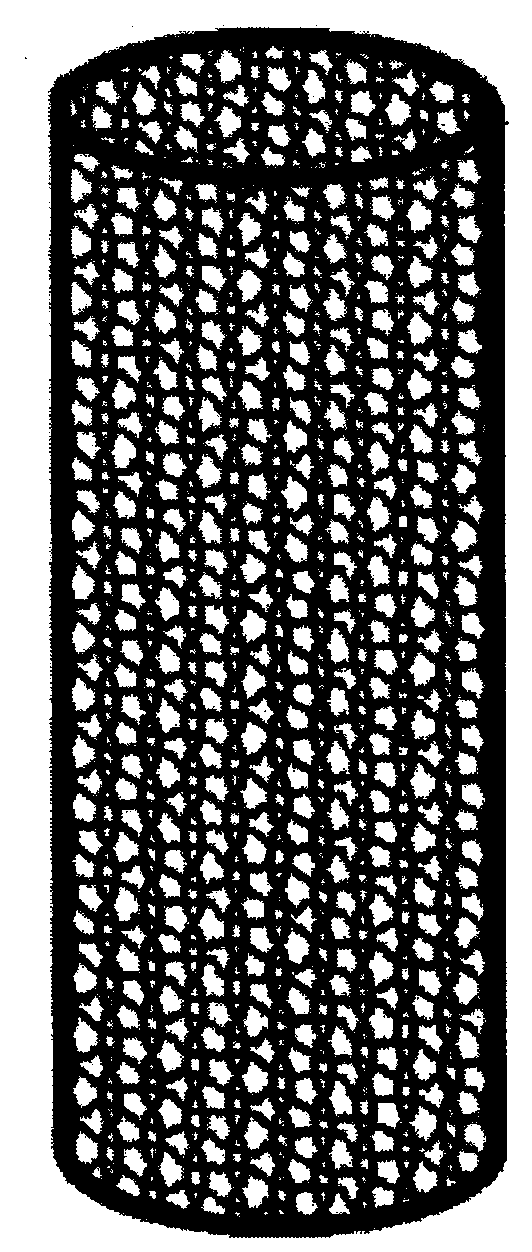

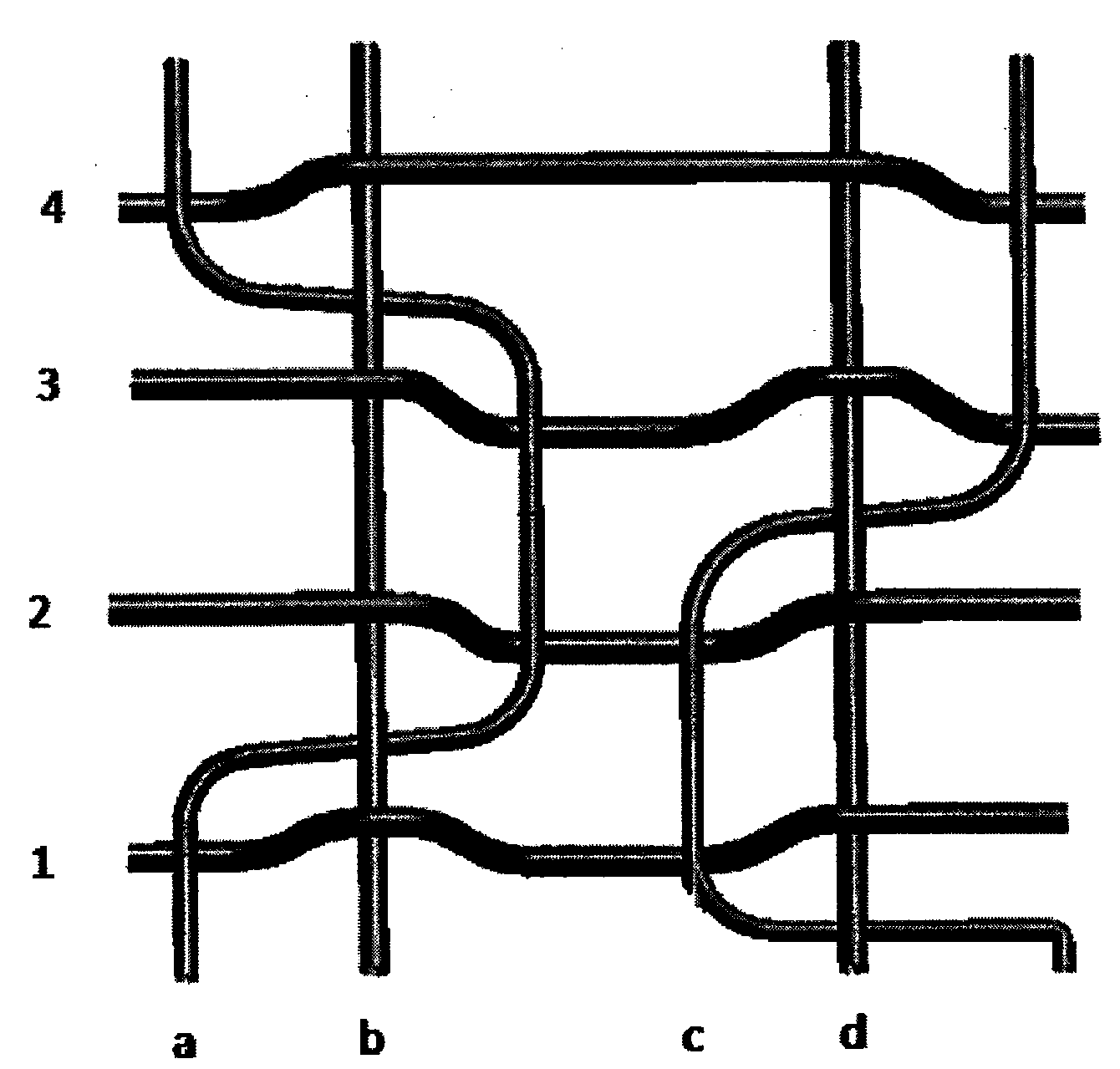

[0023] Both the circumferential filament and the axial filament are polyester filaments with a diameter of 0.2 mm. This embodiment provides a tracheal stent with twisted wire structure, which is composed of a twisted unit formed by twisting circumferential filaments and axial filaments to form a tubular structure. Axial filament one a, axial filament two b, axial filament three c, and axial filament four d are four axial filaments in one cycle, wherein axial filament one a and axial long Wire two b forms a twisting unit one, axial filament three c and axial filament four d form twisting unit two, and the two twisting units and the circumferential filaments are twisted in the following ways: figure 2 Shown:

[0024] The twisting method of the circumferential filament 1 is: in the twisting unit 1, the axial filament 1 a is on the left side of the axial filament 2 b, while the axial filament 1 a is on the circumferential filament 1, and the axial filament 1 is on the left side ...

Embodiment 2

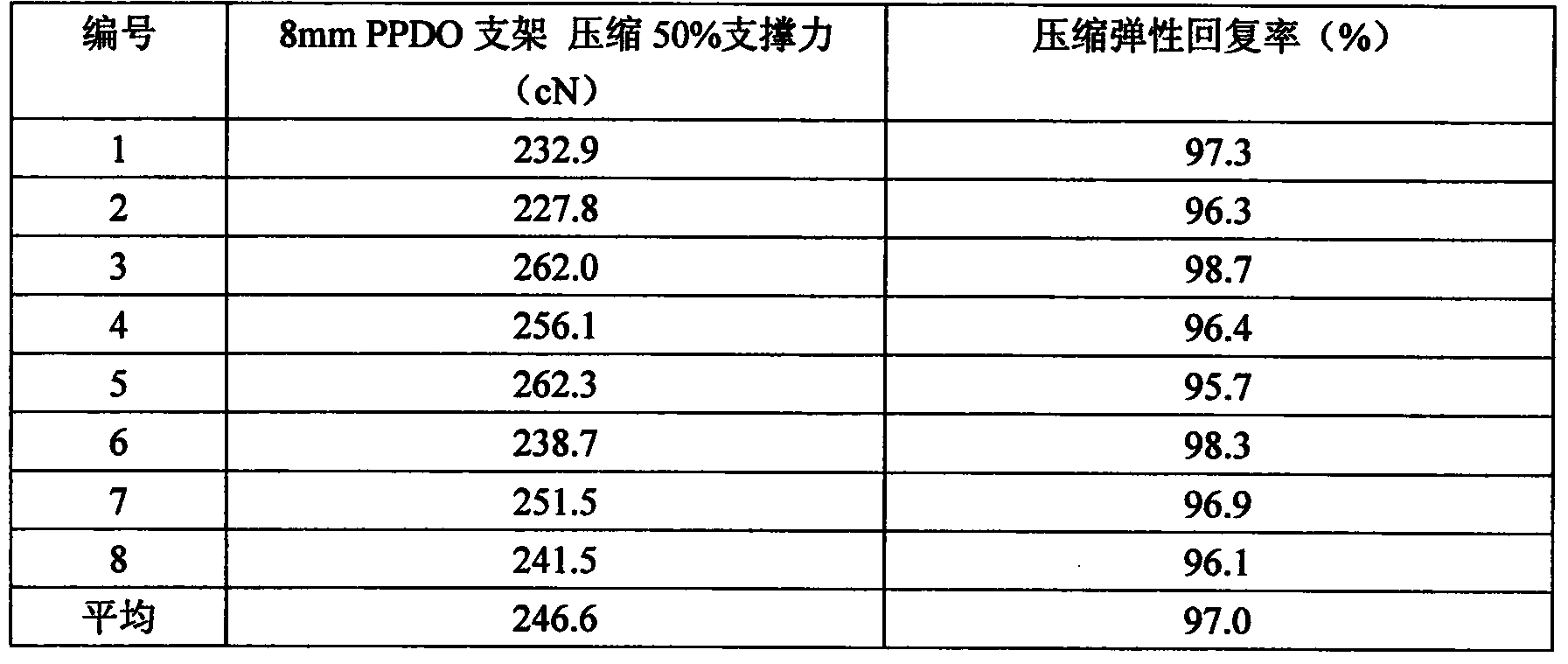

[0030] Both the circumferential filament and the axial filament are polydioxanone (PPDO) filaments with a diameter of 0.15mm. This embodiment provides a tracheal stent with twisted wire structure, which is composed of a twisted unit formed by twisting circumferential filaments and axial filaments to form a tubular structure. Axial filament one a, axial filament two b, axial filament three c, and axial filament four d are four axial filaments in one cycle, wherein axial filament one a and axial long Wire two b forms a twisting unit one, axial filament three c and axial filament four d form twisting unit two, and the two twisting units and the circumferential filaments are twisted in the following ways: figure 2 Shown:

[0031] The twisting method of the circumferential filament 1 is: in the twisting unit 1, the axial filament 1 a is on the left side of the axial filament 2 b, while the axial filament 1 a is on the circumferential filament 1, and the axial filament 1 is on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com