A processing technology of Beihan water stone

A Beihan water stone and processing method technology, applied in the direction of active ingredients such as aluminum/calcium/magnesium, can solve the problems of unqualified sanitary test results, high temperature requirements, complicated process steps, etc., and achieve the elimination of sterilization steps , Simplify the process flow, optimize the effect of process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

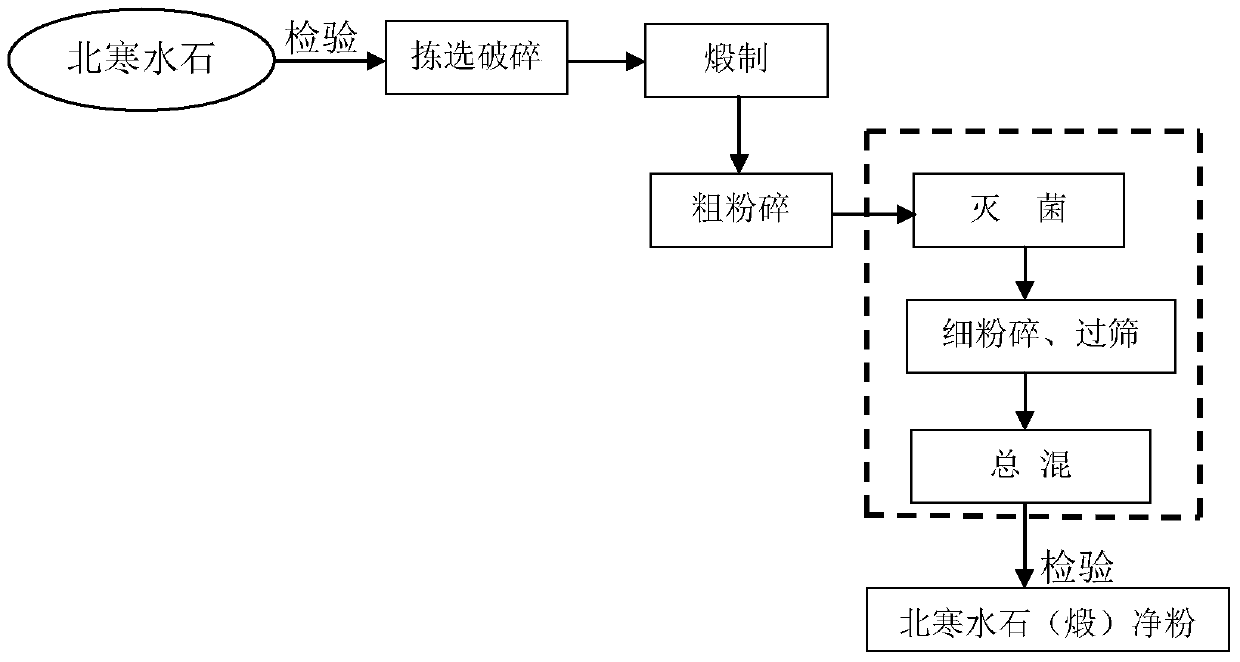

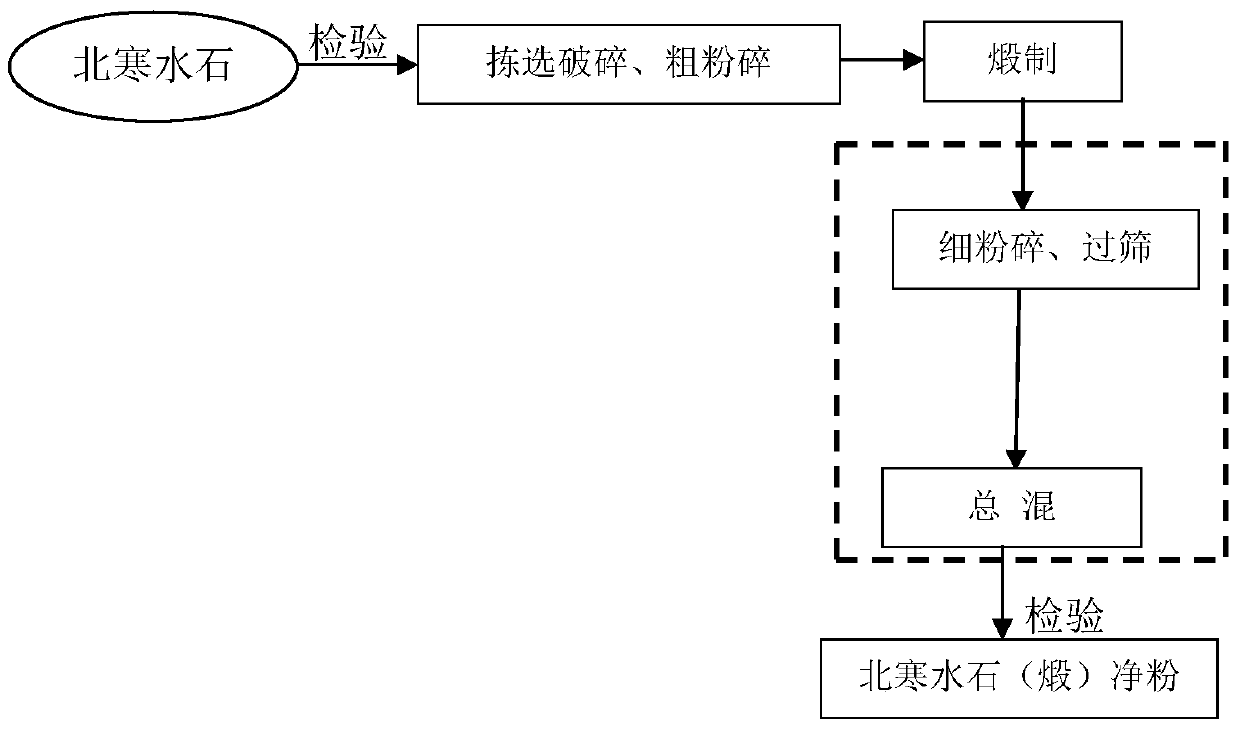

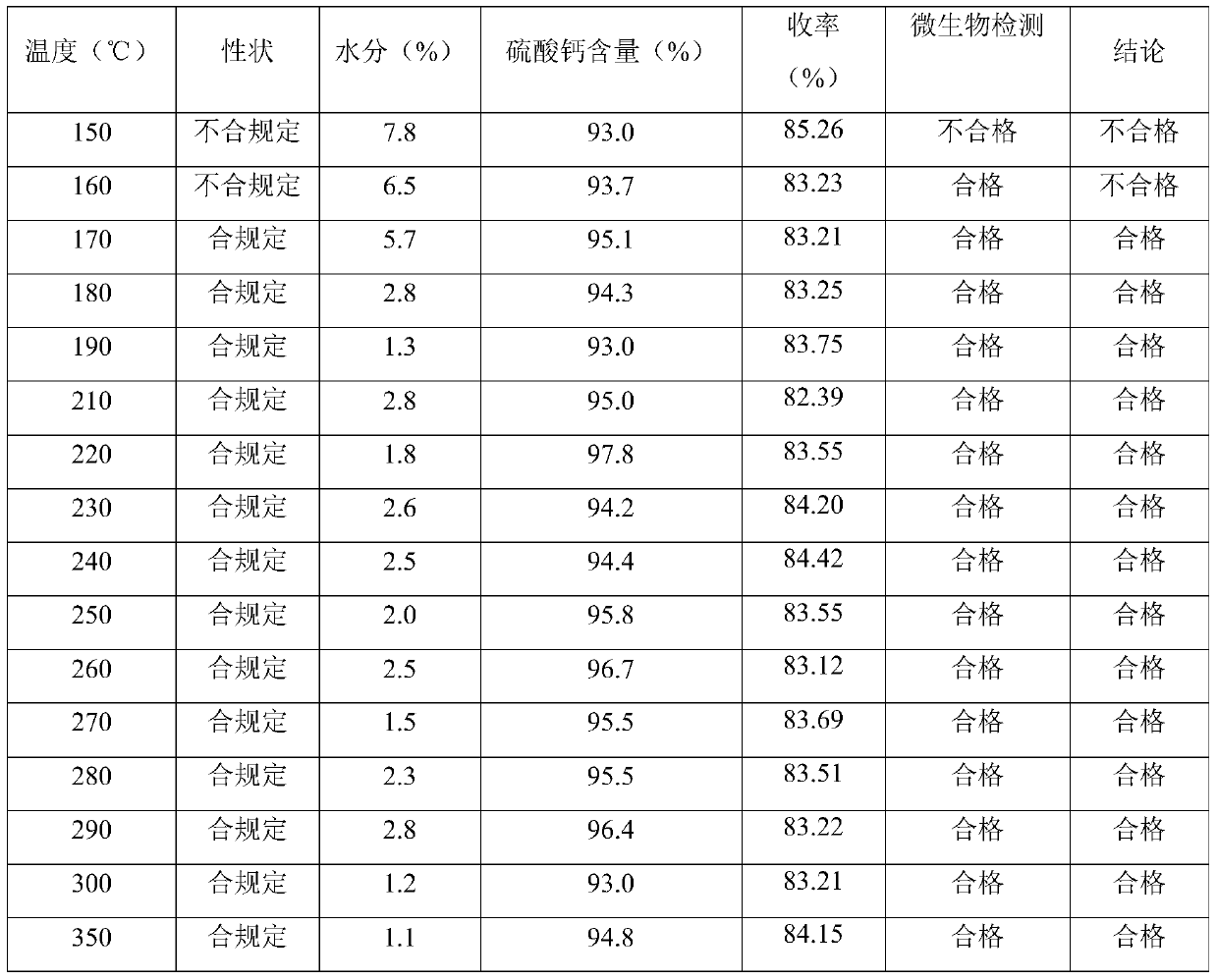

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 A kind of north cold water stone processing technology, comprises the following steps:

[0037] (1) Selection and crushing, coarse crushing: selecting and removing the impurities in the Beihan water stone, and then crushing the selected Beihan water stone into blocks with a diameter less than or equal to 1cm, and the size of the block medicines is basically the same; The Beihanshui stone is put into the traditional Chinese medicine crushing machine (installing a sieve with a 7.0mm aperture) for pulverization;

[0038] (2) Calcining: Put the pulverized Beihan water stone in a tunnel oven, set the temperature at 170°C, and calcining for 3 hours;

[0039] (3) Fine crushing: Pour the Beihan water stone powder cooled to room temperature into a pulverizer (80 mesh screen installed) for pulverization;

[0040] (4) Sieving: transfer the pulverized Beihan water stone powder to a powder sieving machine (with a 80-mesh sieve installed) for sieving, and the coarse par...

Embodiment 2

[0042] Embodiment 2 A kind of north cold water stone processing technology, comprises the following steps:

[0043] (1) Selection and crushing, coarse crushing: selecting and removing the impurities in the Beihan water stone, and then crushing the selected Beihan water stone into blocks with a diameter less than or equal to 1cm, and the size of the block medicines is basically the same; The Beihanshui stone is put into the traditional Chinese medicine crushing machine (installing a sieve with a 7.0mm aperture) for pulverization;

[0044] (2) Forging: Put the crushed Beihan water stone into the tunnel oven (set in the partition wall between the general area and the clean area, with a door on the side of the general area and the side of the clean area), set the temperature at 170 ℃, forging for 4 hours; since the cleanliness of the clean area is much higher than that of the general area, the tunnel oven is set in the partition wall between the general area and the clean area, an...

Embodiment 3

[0048]Embodiment 3 A kind of north cold water stone processing technology, comprises the following steps:

[0049] (1) Selection and crushing, coarse crushing: selecting and removing the impurities in the Beihan water stone, and then crushing the selected Beihan water stone into blocks with a diameter less than or equal to 1cm, and the size of the block medicines is basically the same; The Beihanshui stone is put into the traditional Chinese medicine crushing machine (installing a sieve with a 7.0mm aperture) for pulverization;

[0050] (2) Forging: Put the crushed Beihan water stone into the tunnel oven (set in the partition wall between the general area and the clean area, with a door on the side of the general area and the side of the clean area), set the temperature at 170 ℃, forging for 5 hours; once forged through, the fire cannot be stopped in the middle, to prevent the phenomenon of sandwiching;

[0051] (3) Fine crushing: Pour the Beihan water stone powder cooled to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com