Flat dripping head

A flat, dripper technology, applied in the field of agricultural water-saving irrigation equipment, can solve the problems of destroying the characteristics of the dripper flow channel, not having the ability to resist rolling, and blocking the flow of the dripper, achieving uniform layout, significant anti-clogging ability, Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

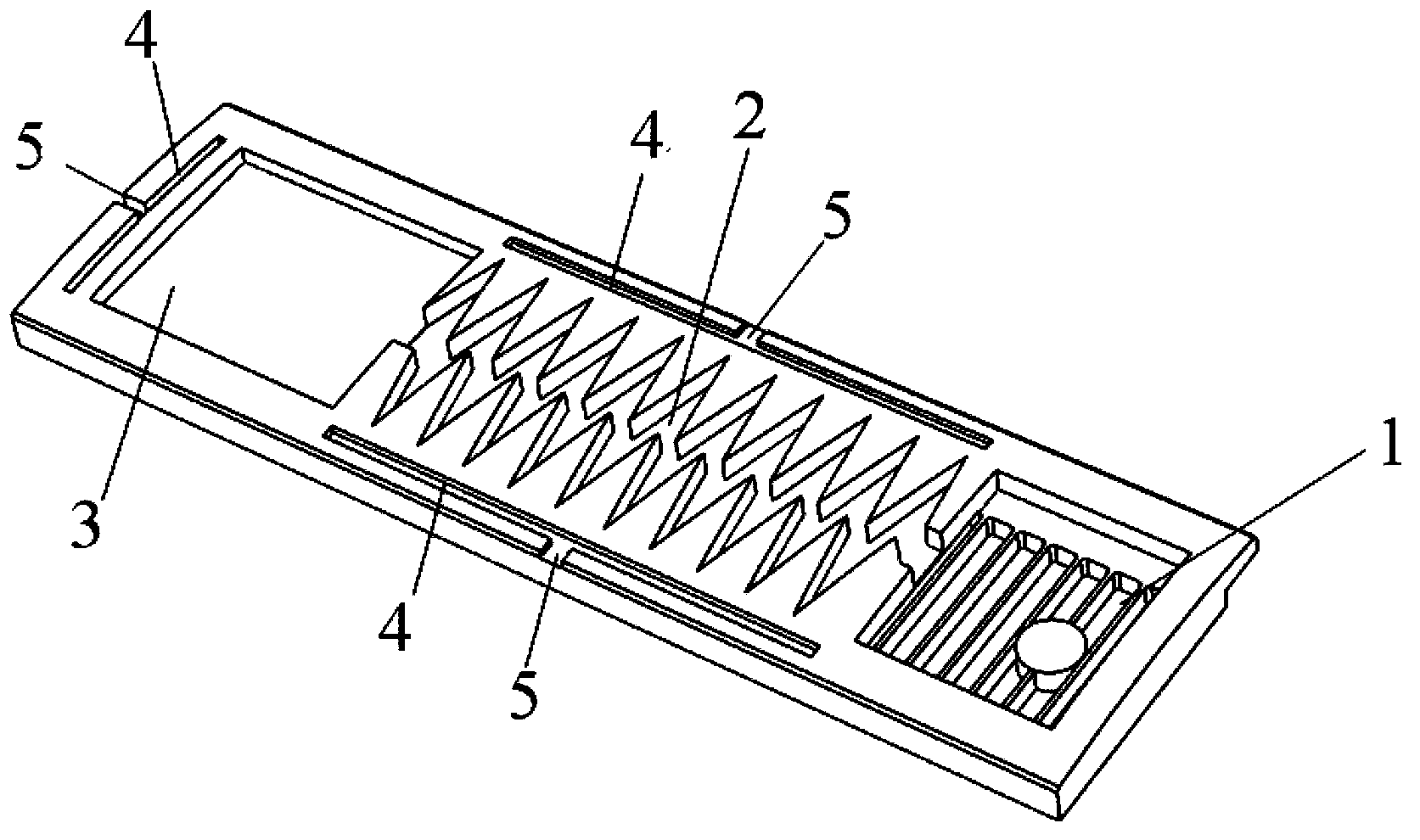

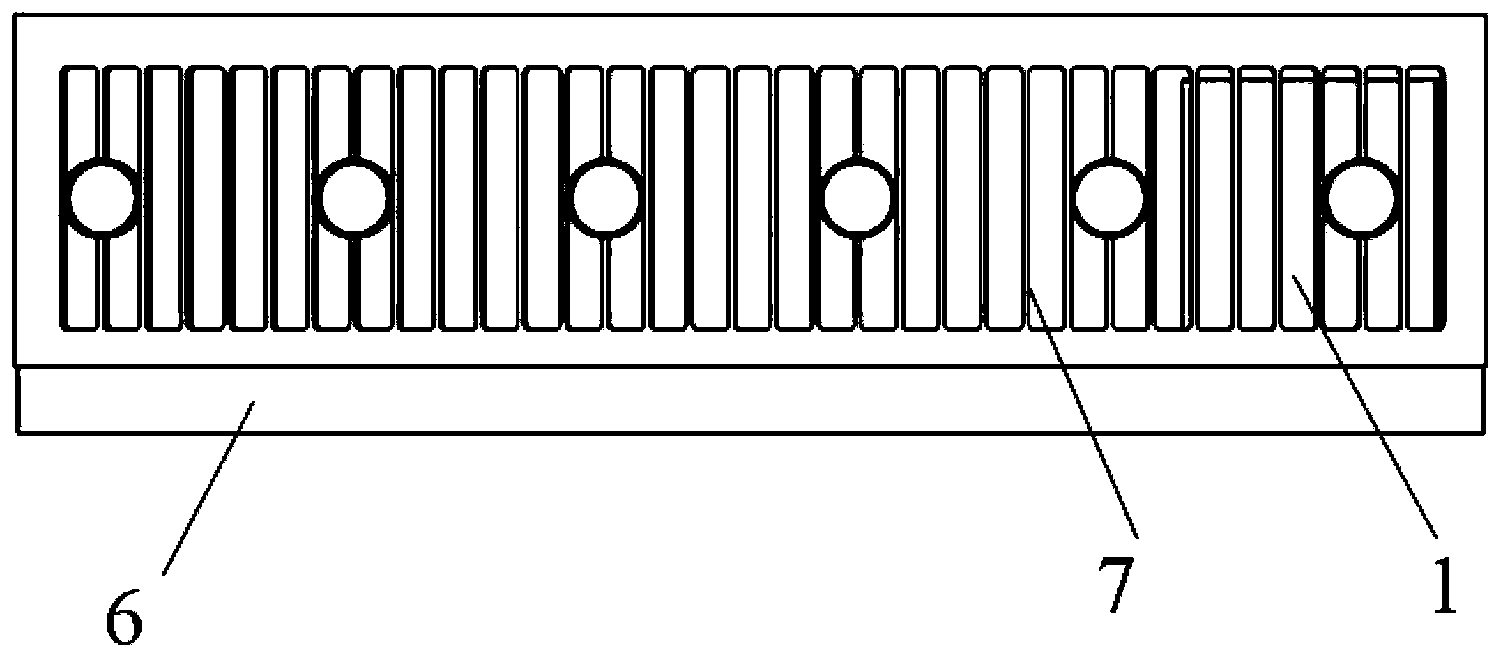

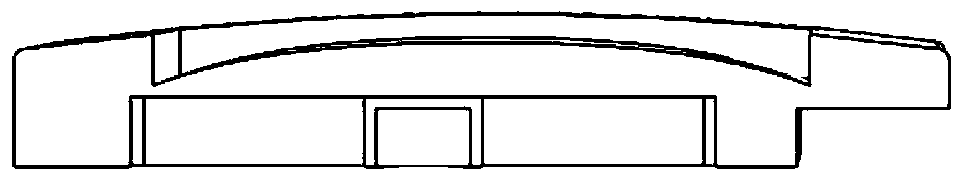

[0015] Such as Figure 1-Figure 3 As shown, a flat dripper, which is a flat and long integrated structure, is provided with a water inlet filter window 1 at one end of its adhesive surface, and a narrow, long and sharply turning tooth-shaped flow channel 2 is adjacent to the water inlet filter along the length direction. The window setting, the water inlet filter window 1 is relatively large, which ensures that the water inlet filter window 1 will not be blocked, thereby ensuring the stability of the water intake. The toothed flow channel 2 is designed to be narrow, long and sharply turning. The internal water flow is always kept at high speed, no sediment will be deposited, and the entire channel is kept unobstructed.

[0016] The tooth-shaped flow channel 2 is connected with the water inlet of the water inlet filter window 1, the water outlet of the tooth-shaped f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com