Device for synchronously processing hole and hole plug

A technology for processing holes and power devices, applied in metal processing equipment, wood processing appliances, drilling/drilling equipment, etc., can solve problems such as the difficulty of lasting stability of fixed objects, user troubles, and difficulty in grasping the size and shape of wood strips.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

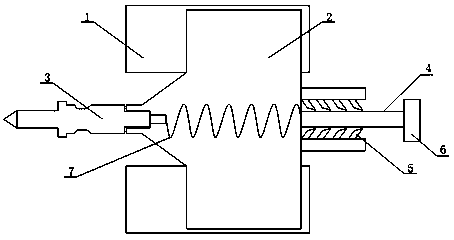

[0012] Such as figure 1 Shown: The embodiment of the present invention provides a device for processing holes and hole plugs at the same time, including a machine base 1, a power device fixed on the machine base 1. The power device here is preferably a motor, in order to take into account both convenience and cost. The gearbox of the gearbox 2 connected to the motor is preferably a high-torque gearbox and needs two output ends. One output end of the gearbox 2 is provided with a drill 3 on the shaft, and the other output end of the gearbox 2 is connected with a circle. Cylindrical slicing device, the slicing device is composed of the feed wooden strip 4 and a cutting knife whose blade is closely attached to the periphery of the feed wooden strip 4, in order to ensure that the wooden strip material can be efficiently processed while drilling through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com