Carbon material penetrated asphalt sintering method

A sintering method and carbon material technology, applied in the sintering field of carbon material pitch infiltration, can solve the problems of many internal voids, low electrical conductivity, easy arcing, etc., and achieve the effects of uniform texture, high electrical conductivity and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

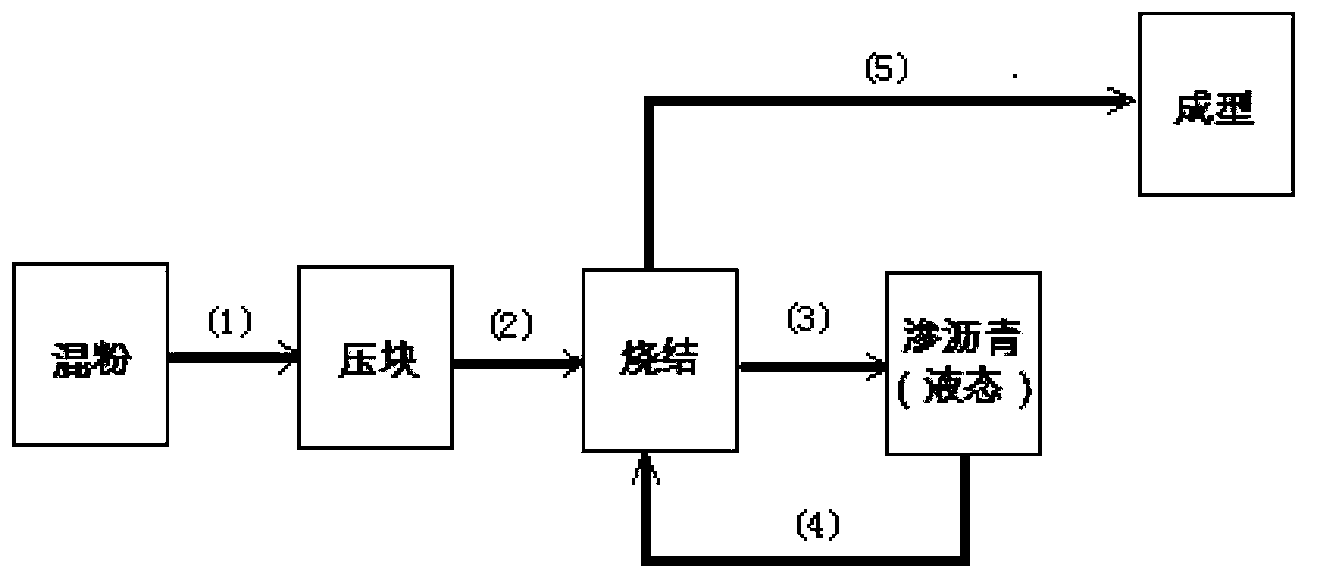

[0020] Such as figure 1 Shown, a kind of carbon material asphalt sintering method comprises the following steps:

[0021] (1): Mix material A;

[0022] (2): Briquetting the mixed material A;

[0023] (3): Sintering the compacted material A;

[0024] (4): Infiltrating the sintered carbon material into material B and sintering;

[0025] The present invention also includes step (5): repeating step (4) several times.

[0026] The material A is carbon powder or a composite material containing carbon molecules or a combination thereof. The material B is asphalt or a material containing asphalt.

[0027] The present invention adopts multiple sintering technology, various carbon materials are mixed, pressed and formed, after one sintering, liquid pitch is infiltrated, and when the pitch fills the inner space, it is sintered again. The structure fusion makes the voids in the material smaller. According to the requirements of different application occasions, it can be infiltrated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com