Creep-resistant long glass fiber reinforced polypropylene material and preparation method and application thereof

A polypropylene material and long glass fiber technology, applied in the field of long glass fiber reinforced polypropylene material and its preparation, can solve the problems of only focusing on material processing, mechanical and thermo-oxidative aging properties, and unable to provide material creep resistance, etc. Achieve the effect of avoiding uneven dispersion of glass fiber, highlighting mechanical properties and impact resistance, and uniform flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Example 1: Preparation of creep-resistant long glass fiber reinforced polypropylene material and its use in front-end frame of automobile

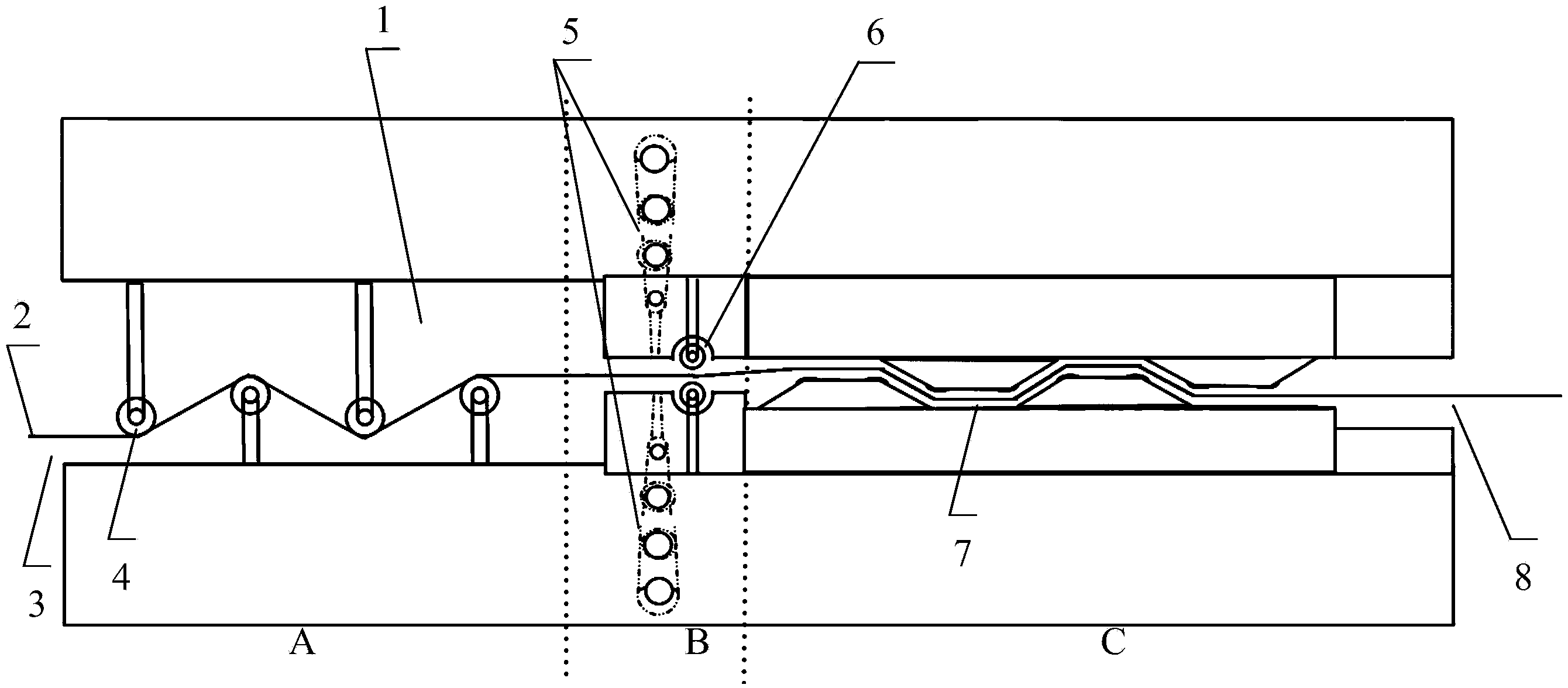

[0056] Prepare the materials according to the formula described in Table 1. The cross-section diagram of the impregnation head is shown in figure 1 , where A is the glass fiber pre-dispersion area, B is the resin double-sided infiltration glass fiber area, C is the glass fiber redispersion area, 1 is the impregnation channel, 2 is the long glass fiber, 3 is the inlet, 4 is the tension roller, 5 Channel for distributing both sides of resin, 6 for calender roll, 7 for glass fiber redispersion channel, 8 for outlet. Weigh the other components except the long glass fiber according to their dosage ratio, after mixing evenly, add the twin-screw extruder with the length-to-diameter ratio of 48:1, melt and knead at the temperature of 220-250°C, extrude and inject Resin double-sided distribution flow channel 5; continuous long glass fiber ...

Embodiment 2

[0060] Example 2: Preparation of creep-resistant long glass fiber reinforced polypropylene material applied to automobile sunroof frame

[0061] Materials were prepared according to the formula described in Table 2. Weigh the other components except the long glass fiber according to their dosage ratio, mix them evenly, add them into a twin-screw extruder with a length-to-diameter ratio of 40:1, melt and knead at a temperature of 250-350°C, extrude and inject The resin double-sided distribution flow channel 5; the continuous long glass fiber 2 enters the impregnation flow channel 1 from the entrance 6 of the glass fiber pre-dispersion area A, passes through the tension roller 4, and enters the resin double-sided infiltration glass fiber area B, and the upper and lower two sides After the side-injected resin is in contact, it passes through the calender roller 6 and enters the glass fiber redispersion zone C, where it is further impregnated in the glass fiber redispersion flow c...

Embodiment 3

[0064] Example 3: Preparation of creep-resistant long glass fiber reinforced polypropylene material applied to electric tool base

[0065] Materials were prepared according to the formulations described in Table 3. Weigh the other components except the long glass fiber according to their dosage ratio, mix them evenly, add them into a twin-screw extruder with a length-to-diameter ratio of 32:1, melt and knead at a temperature of 180-280°C, extrude and inject The resin double-sided distribution flow channel 5; the continuous long glass fiber 2 enters the impregnation flow channel 1 from the entrance 3 of the glass fiber pre-dispersion area A, passes through the tension roller 4, and enters the resin double-sided infiltration glass fiber area B, and the upper and lower two sides After the side-injected resin is in contact, it passes through the calender roller 6 and enters the glass fiber redispersion zone C, where it is further impregnated in the glass fiber redispersion flow ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com