Washing machine and control method thereof

A control method and technology for washing machines, which are applied to control devices of washing machines, other washing machines, washing devices, etc., can solve problems such as washing 3-4 kg, unclean washing, contact friction of internal components of washing machines, etc. Friction-avoiding, high-reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

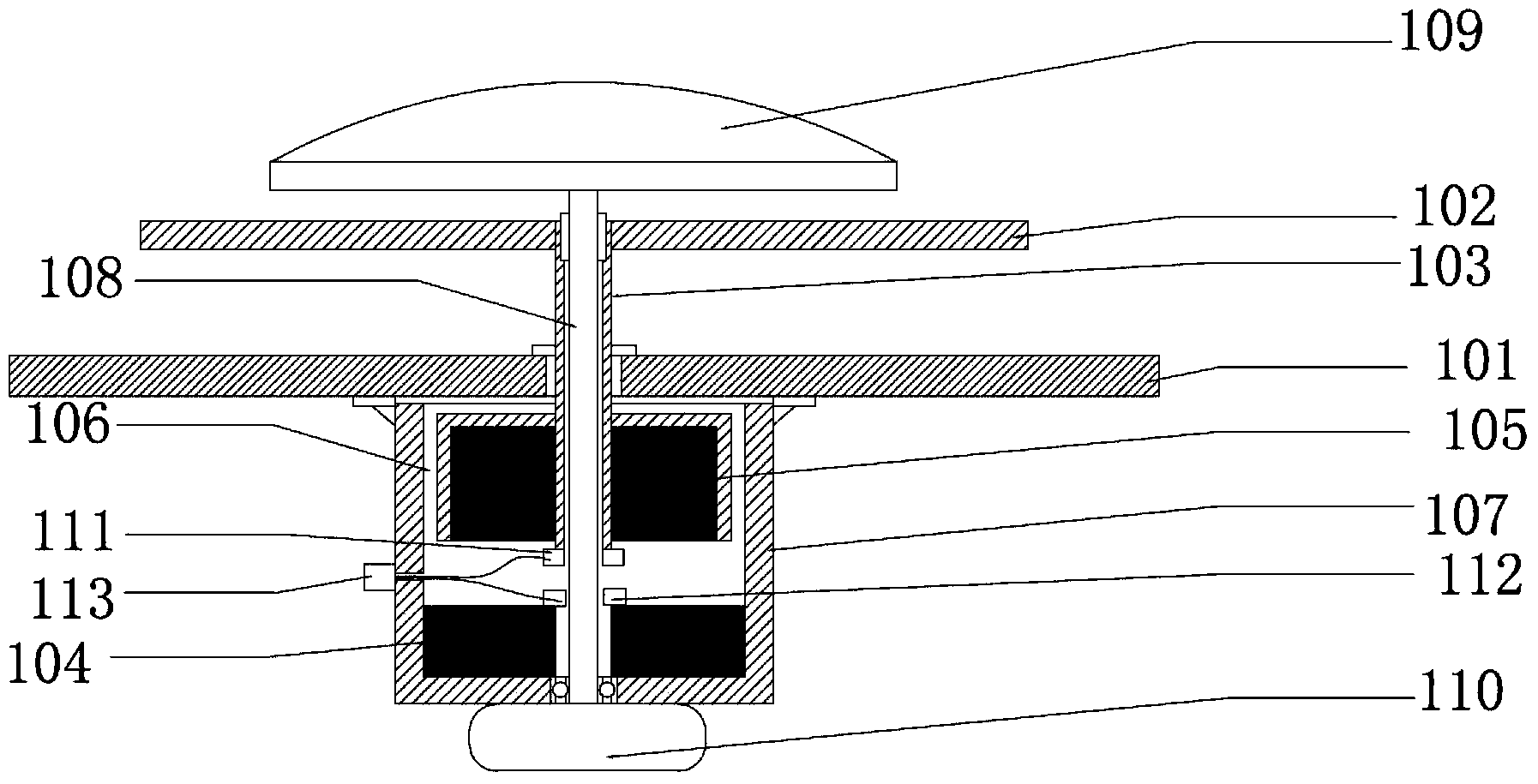

[0011] Such as figure 1 As shown, a washing machine includes an inner cylinder 102 and an outer cylinder 101, and also includes two magnets arranged in cooperation with the outer cylinder 101 and the inner cylinder 102. The inner cylinder 102 is suspended in the outer cylinder 101 by the repulsive force between the two magnets, and the two magnets A detection component for monitoring the distance between the two is arranged between them.

[0012] The inner cylinder 102 is suspended in the outer cylinder 101 by the repulsive force between the two magnets, so that the inner cylinder 102 has almost no mechanical contact with the outer cylinder 101 during rotation, thereby effectively reducing friction and reducing noise.

[0013] In addition, clothes and water are housed in the inner cylinder 102 during the washing process, and the inner cylinder 102 sinks under the action of gravity, and the magnets arranged in cooperation with the inner cylinder 102 will also sink. If there are...

Embodiment 2

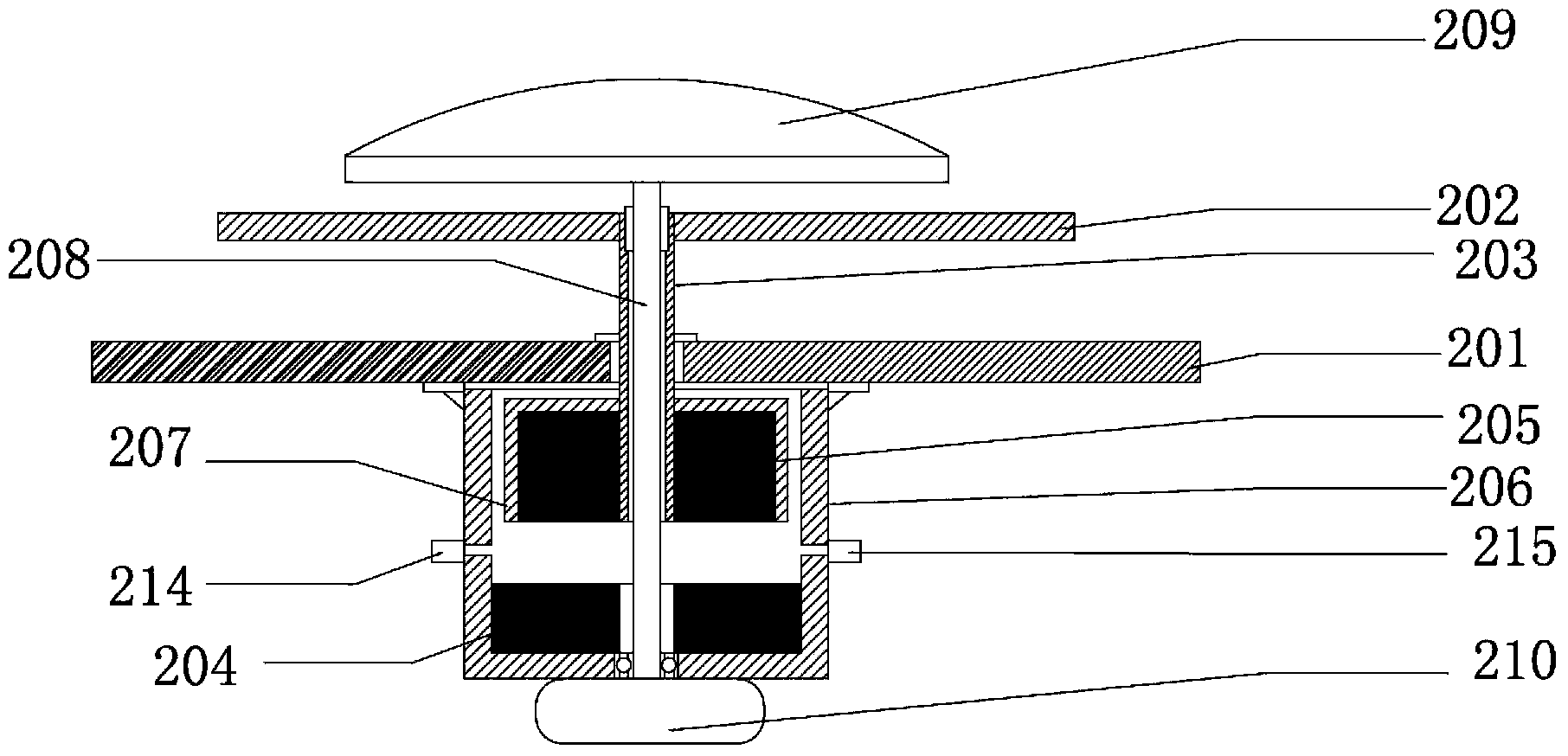

[0030] Such as figure 2 As shown, the washing machine provided in this embodiment includes an inner cylinder 202, an outer cylinder 201, and two magnets arranged in cooperation with the outer cylinder 201 and the inner cylinder 202. The inner cylinder 202 is suspended in the outer cylinder through the repulsive force between the two magnets. A detection component for monitoring the contact between the magnets is arranged.

[0031] The structure of the washing machine provided in this embodiment is roughly the same as that in Embodiment 1. The detection component is connected to the alarm device. The bottom of the inner cylinder 202 is provided with a hollow connecting shaft 203 for supporting the inner cylinder 202. The hollow part of the connecting shaft 203 is provided with a pulsator shaft. 208, one end of the pulsator shaft 208 passes through the bottom of the inner cylinder 202 and is coaxially connected with the pulsator 209, and the other end of the pulsator shaft 208 ...

Embodiment 3

[0039] This embodiment provides a washing machine control method, including: monitoring the distance between two magnets arranged in cooperation with the outer cylinder and the inner cylinder through a detection component, wherein the inner cylinder is suspended in the outer cylinder by the repulsive force between the two magnets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com