Sectional continuous floating-resistant cast-in-situ hollow slab

A segmented continuous, hollow slab technology, applied in floors, building components, buildings, etc., can solve the problems of easy-to-deform installation effect, high construction cost, low construction efficiency, etc., to achieve good economy and applicability, and good installation effect. , the effect of easy installation of pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

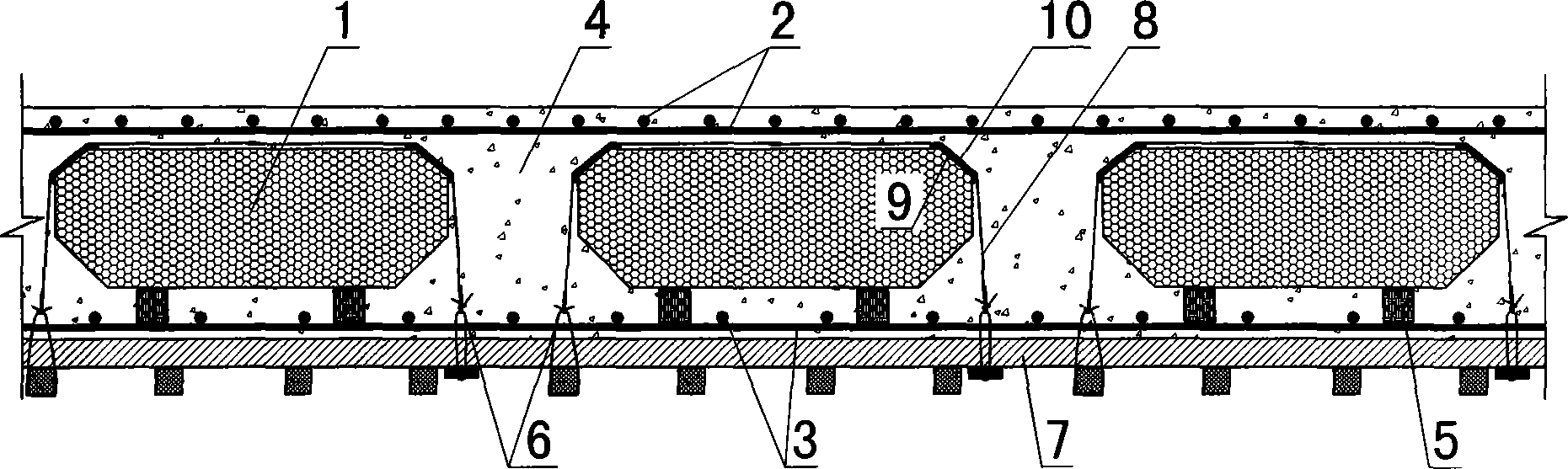

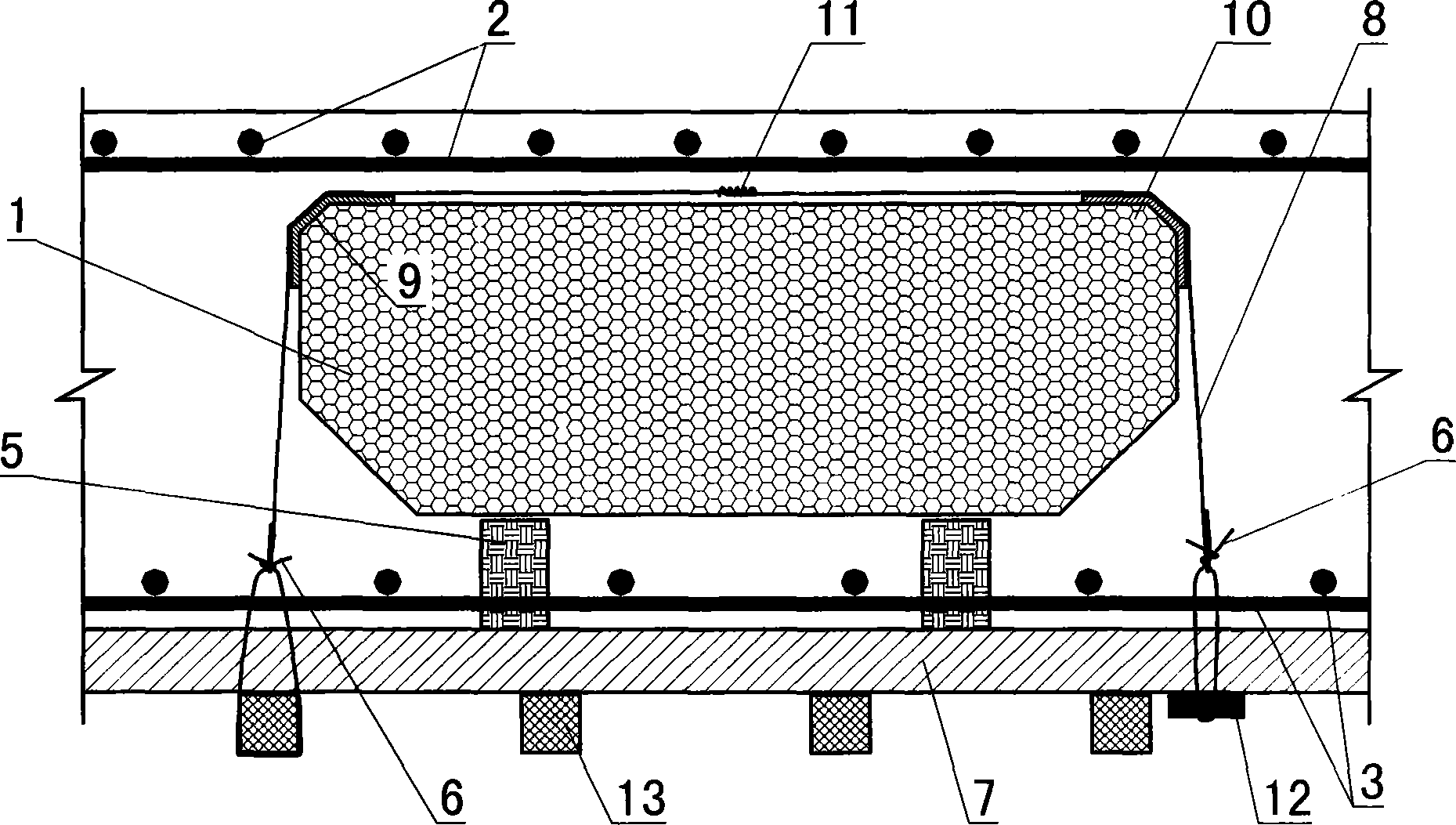

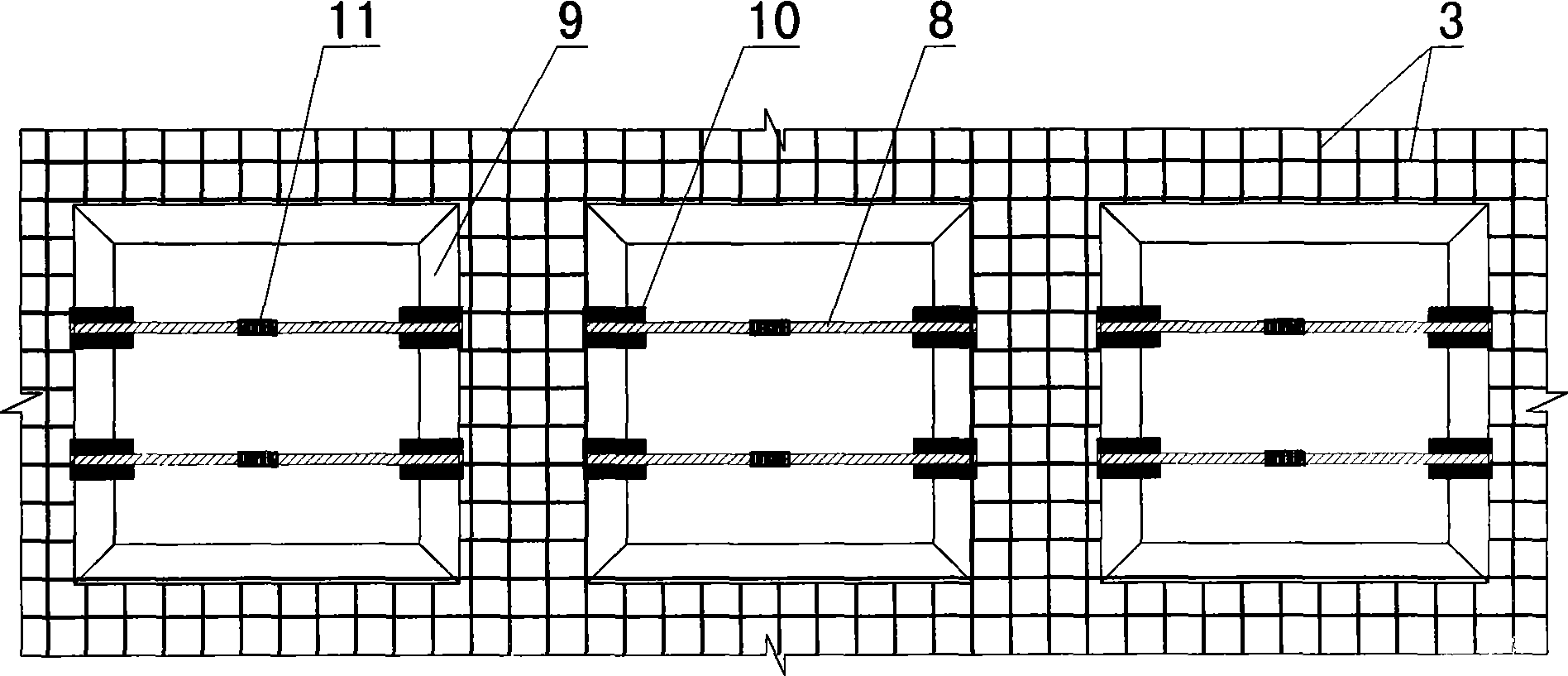

[0032] Below, refer to the attached picture , the present invention is described, and the present invention is realized in the following manner:

[0033] exist picture 1, picture 2, picture In the embodiment shown in 3, a piecewise continuous anti-floating cast-in-place hollow slab, the hollow slab includes a filling body (1), lower steel bars (3) and concrete (4), and the filling body (1) is located in the hollow slab The top of the lower steel bar (3) is permanently buried in the concrete (4), the main material of the filling body (1) is light foam material, the bottom of the filling body (1) has a positioning pad (5), and the anti-floating iron wire ( 6) Pass through the template (7), the fixing belt (8) is a non-metal strip, the cross section of the fixing belt is flat, the ratio of the width to the thickness of the fixing belt (8) is greater than or equal to 5, and the width of the fixing belt is ≥ 6mm, the fixing belt (8) bypasses the side and upper part of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com