Method for staged fracturing of well cementation casing string and tool for method

A cementing and fracturing technology, which is applied to wellbore/well valve devices, earthwork drilling, wellbore/well components, etc. It can solve the problem of cementing plugs that are difficult to replace cement slurry, sliding sleeve cementation, separation, etc. The problems such as the failure of section fracturing construction have been solved, and the implementation process has been simplified, the reliability is high, and the success rate of bumping is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

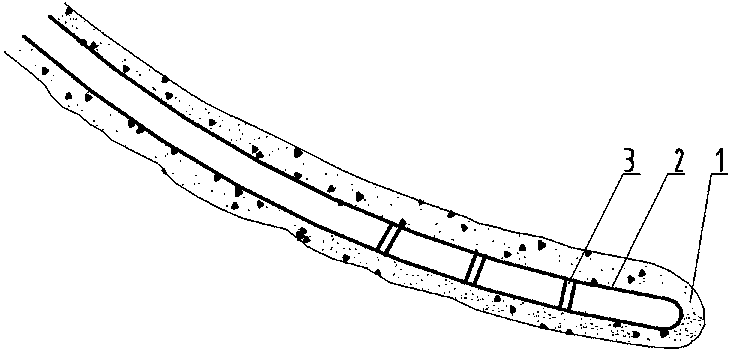

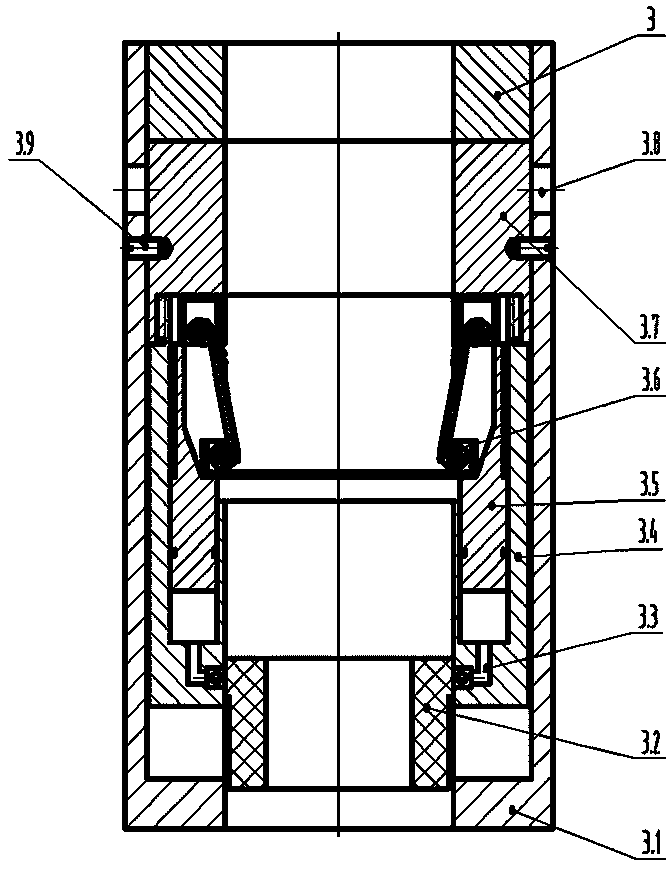

[0009] The present invention is described in detail below in conjunction with accompanying drawing: the method for staged fracturing of cementing string is: a, according to design, determine the interval that needs to be fractured in the implementation of the well, to determine the required hydraulic variable diameter ball seat sleeve sliding sleeve switch tool (3) the quantity and position; b, from the bottom of the well to the well head, arrange the hydraulic variable diameter ball seat casing sliding sleeve switch tool (3) in the order of small to large diameter after the ball seat is reduced in diameter; c, put the hydraulic pressure The variable-diameter ball seat casing sliding sleeve switch tool (3) is connected in series in the casing string (2) according to the design and goes downhole; d. When the casing is lowered to the designed depth, cement slurry is driven into the well for cementing operation, and the The casing is fixed in the formation (1), and after cementin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com