Automobile automatic dust removal device

An automotive and automatic technology, applied in the direction of exhaust devices, mufflers, engine components, etc., can solve the problems of reducing the intake air volume of the engine, increasing the intake air resistance, affecting the performance of the engine, etc., to reduce the cost and improve the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

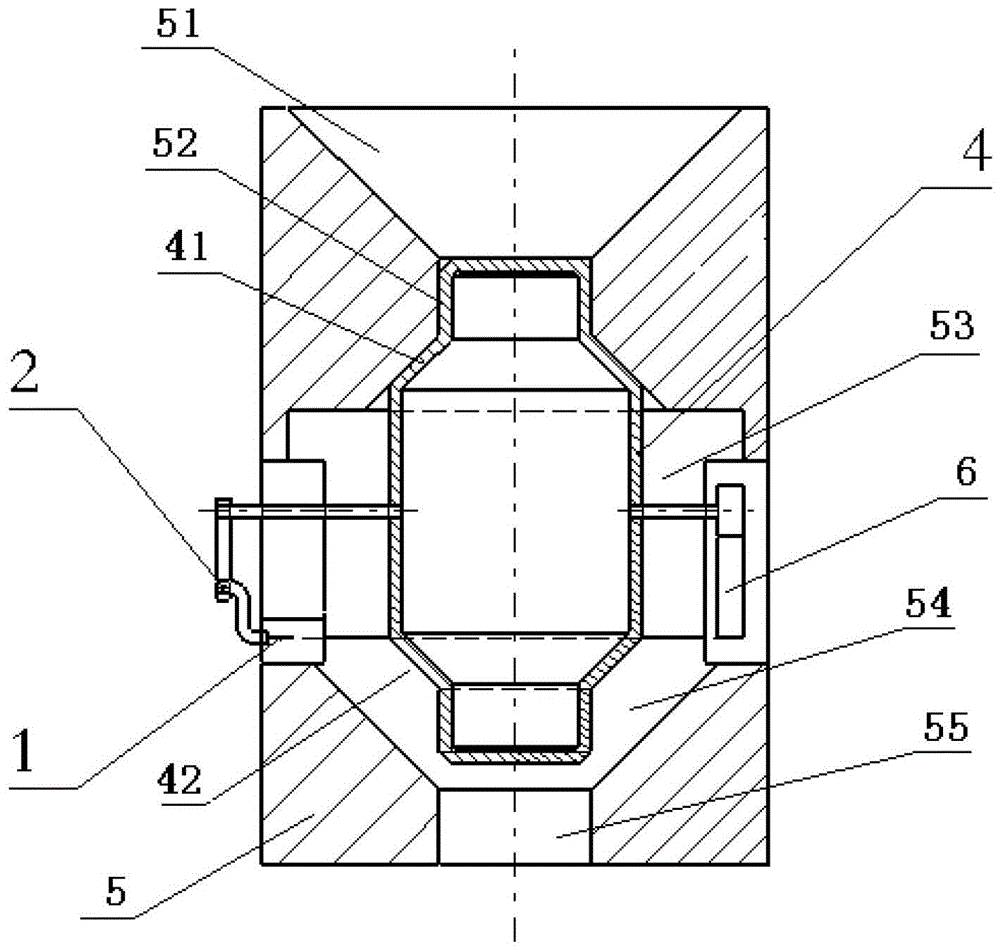

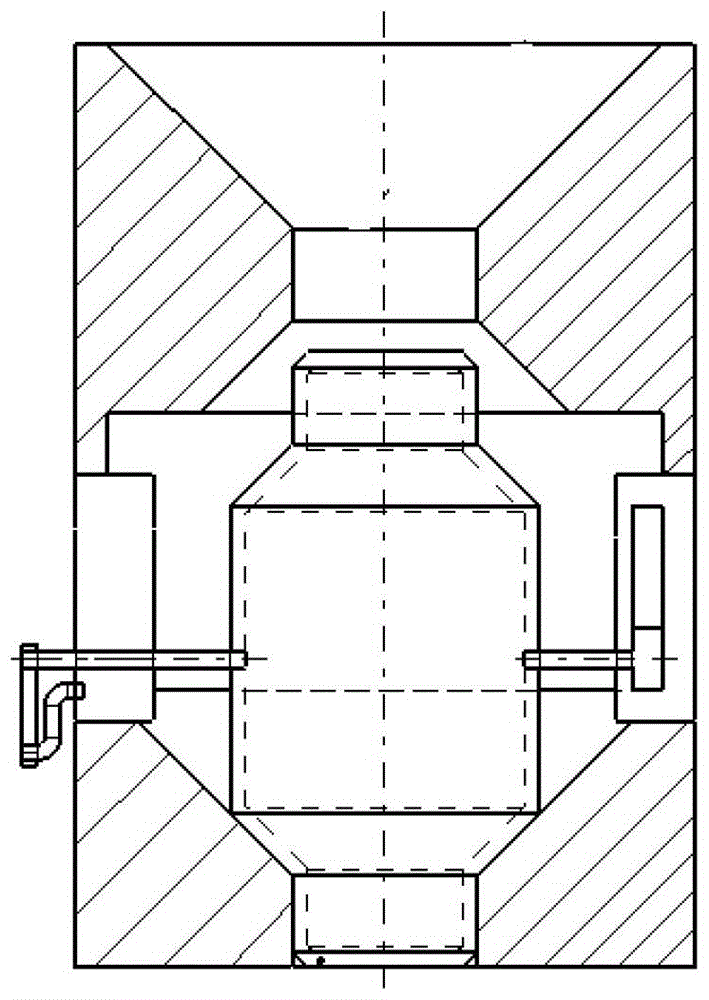

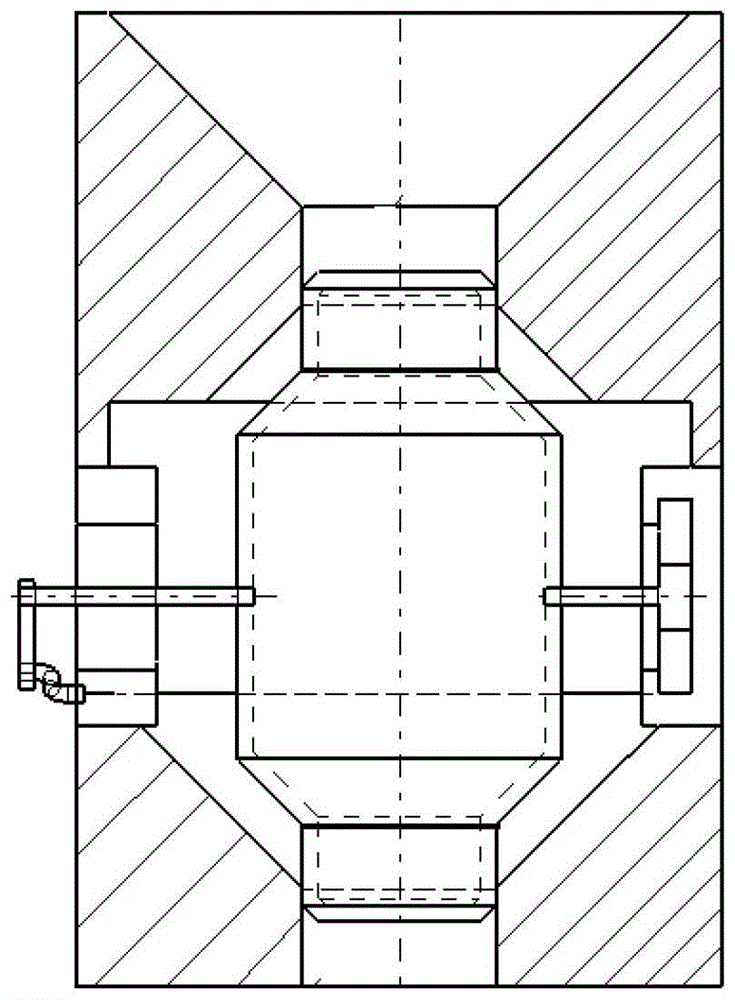

[0018] Such as figure 1 As shown, this kind of automobile automatic dust removal device includes: a housing 5, a piston 4, a motor 1 and a crank connecting rod mechanism 2. The interior of the housing 5 is provided with a temporary storage chamber 51, a dust inlet 52, a cavity 53, a dust storage chamber 54, and a dust discharge outlet 55 from top to bottom in sequence, and the piston 4 and the motor 1 are both arranged in the cavity 53. The output end of the motor is connected with the side wall of the piston 4 via a crank linkage.

[0019] In order to speed up the flow rate of dust downwards, the cross sections of the temporary storage chamber 51 and the dust storage chamber 54 are both wedge-shaped, and the lower bottom of the wedge is gradually tightened to communicate with the dust inlet and the dust outlet respectively. In order to form a better sealing effect, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com